Metal substrate functional part and additional material processing preparation method thereof

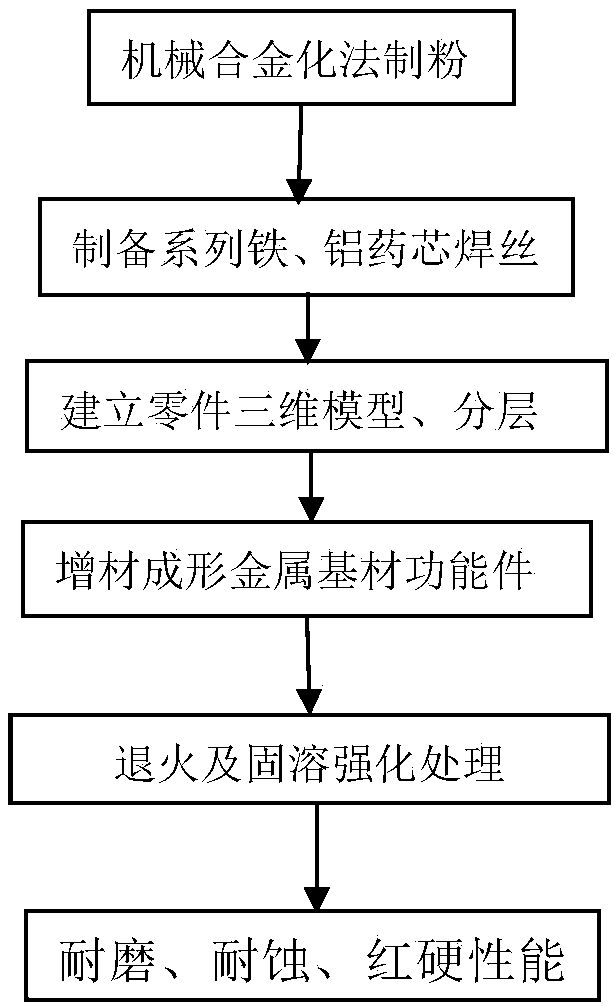

A technology of metal substrates and functional parts, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of continuous and smooth distribution of components, small size of gradient materials, and poor interlayer bonding force, etc., to achieve the elimination of macroscopic Interface, good heat resistance, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

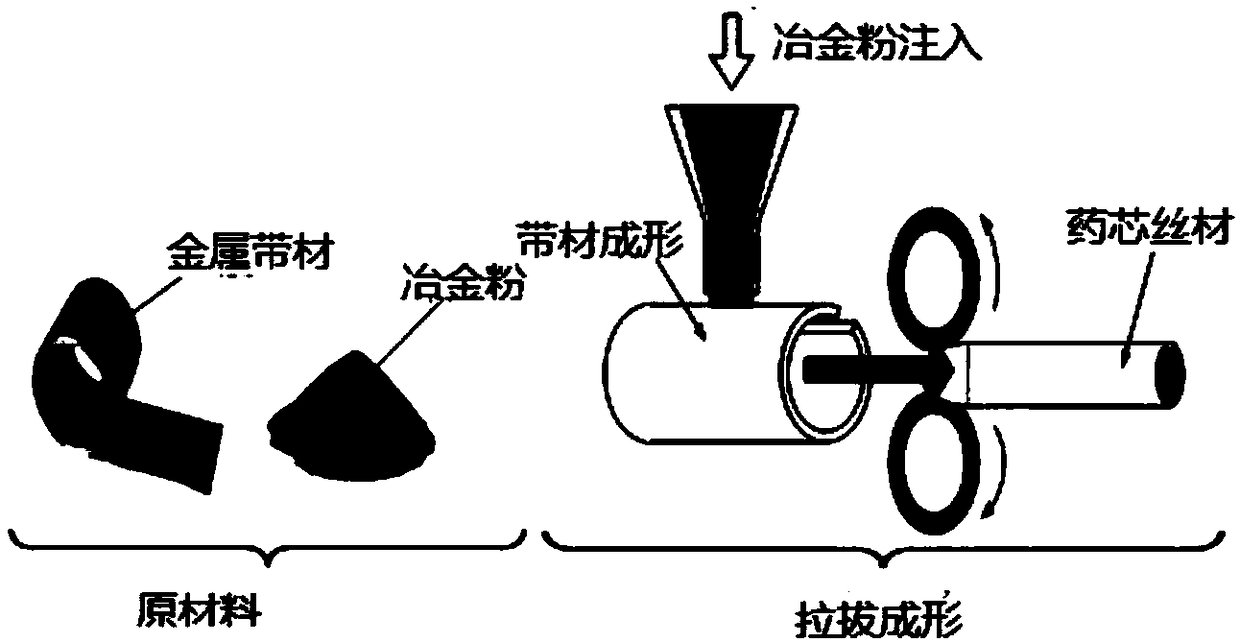

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

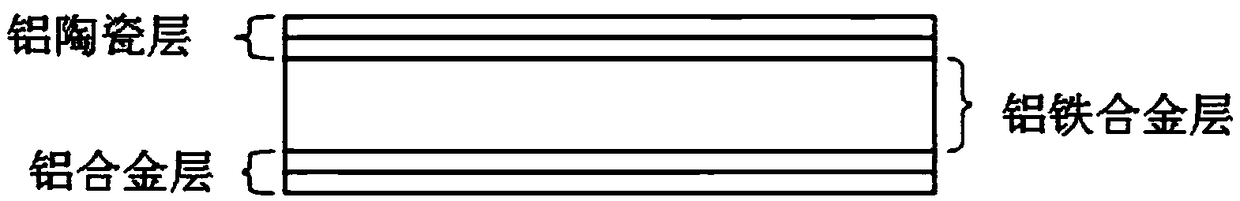

[0032] see figure 2 As shown, the present invention provides a metal substrate functional part, including an aluminum alloy layer, an aluminum-iron alloy layer and an aluminum ceramic layer, wherein the aluminum ceramic layer is coated on the aluminum-iron alloy layer, and the aluminum-iron alloy layer is coated on the aluminum alloy layer layer; the aluminum-iron alloy layer includes a plurality of aluminum-iron alloy sub-layers, and in the direction from the aluminum alloy layer to the aluminum-ceramic layer, the iron content of each layer of aluminum-iron alloy sub-layers increases layer by layer, preferably, the aluminum-ceramic layer includes A plurality of aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com