High adhesion thermal ink jet ink

A thermal inkjet, ink composition technology, applied in inks, household appliances, applications, etc., can solve the problems of long drying time and poor adhesion of inks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This example illustrates an embodiment of a thermal inkjet ink composition using methyl ethyl ketone as a solvent. The materials used in the preparation of the inkjet ink compositions, their amounts in percent and formulation numbers are listed in Table 1 below. Nobel DHX 3-4 is a nitrocellulose resin with a weight average molecular weight of about 42,000. Joncryl 682 is a styrene / acrylic copolymer with a weight average molecular weight of about 1700. Ad Pro MTS is a sulfonamide modified epoxy polymer with a weight average molecular weight of about 1700. K-Plast 1022 is a urethane polymer with a weight average molecular weight of about 7500. DC Silicone resin is a silicone resin with a weight average molecular weight of about 2500. Poly-4-hydroxystyrene resin is a branched polymer with a weight average molecular weight of about 2500. Paraloid B-66 is an acrylic polymer with a weight average molecular weight of about 70,000.

[0061]

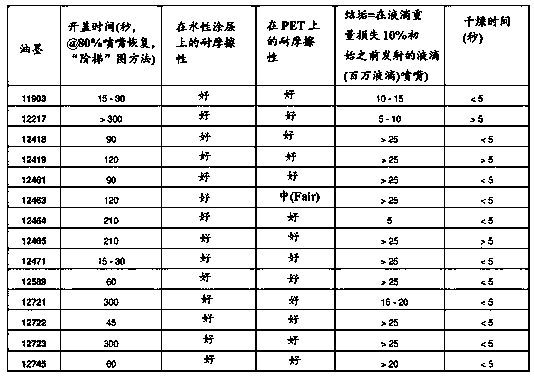

[0062] Table 2 shows the av...

Embodiment 2

[0066] This example illustrates an embodiment of a thermal inkjet ink composition using an ethanol-based solvent. The materials used in the preparation of the inkjet ink compositions, their amounts in percent and formulation numbers are listed in Table 3 below. Nobel DLX 3-5 is a nitrocellulose resin available from Nobel Enterprises. Mowital LPB 16H is a polyvinyl butyral resin available from Kuraray America.

[0067] table 3

[0068]

[0069] Table 4 shows the % drop weight loss for the ink formulations in Table 3 measured as previously described as a function of the number of drops fired per nozzle. It can be seen that Formulations 6259, 6271 and 6322 are sufficiently resistant to fouling to be able to fire at least 10 million drops per nozzle in a thermal inkjet printer without a drop weight loss of more than 10%.

[0070] Table 4

[0071]

Embodiment 3

[0073] This example illustrates an embodiment of a thermal inkjet ink composition using a mixture of ketone and alcohol based solvents. The materials used in the preparation of the inkjet ink compositions, their amounts in percent and formulation numbers are listed in Tables 5-8 below.

[0074] table 5

[0075]

[0076] Table 6

[0077]

[0078] Table 7

[0079]

[0080] Table 8

[0081]

[0082]

[0083] The Composite Adhesion Score is the average of the Rub Adhesion Test and Scratch Adhesion Test scores. The image was printed on a BOPP film substrate commercially used to wrap confectionery. Friction adhesion was tested as follows. A controlled-weight rub tester was constructed using a conventional technique glue rub tightly covered by a thin leather-suede material. A 1 kg steel weight is fixed to the bottom of the covered eraser. A leather surface with a constant 1.0 x 0.5 inch contact area was then brought into contact with 1 inch of the printed code i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com