Device and method for preparing a liquid polymer misture

A technology of liquid polymers and blends, applied in applications, household appliances, household components, etc., can solve the problems of changing the appearance of the final product, insufficient homogenization of polyol compounds, product rejection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

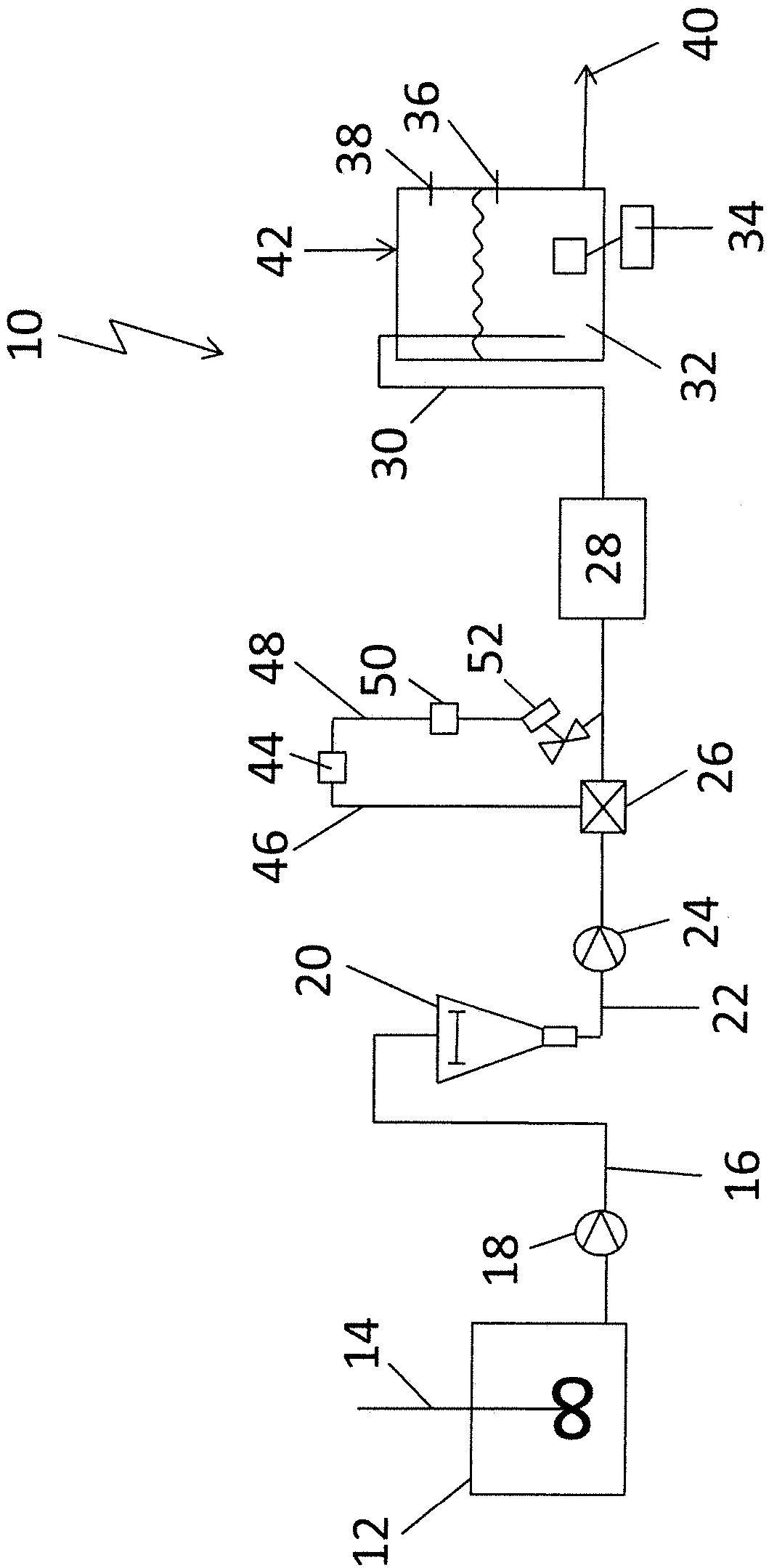

[0018] In the drawing, a plant 10 is shown for the preparation of polyol compounds representing reactive polymers for polyurethane system materials for the production of roof openings for motor vehicles The plastic foam edge of the sliding roof cover of the system.

[0019] The device 10 comprises a storage container 12 in which the polyol compound can be stored and which is provided with an agitator 14 in order to eliminate any stratification of the polyol compound caused by storage. The storage container 12 is connected to a degassing device 20 formed by a vacuum fan via a duct 16 in which a supply pump 18 is arranged. An outlet duct 22 is connected to a vacuum fan, in which outlet duct 22 a further supply pump 24 and a mass flow meter 26 are arranged, and which leads to a homogenization unit 28 formed by a toothed colloid mill. A dosing valve 52 is arranged at the line 16 upstream of the homogenization unit 28, via which dosing valve 52 additive gas can be added to the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com