Pulping equipment used for pulping in curvilinear disturbance type and based on curvilinear motion guiding

A bending and pulping technology, which is applied in textiles and papermaking, raw material separation, papermaking, etc., can solve the problems of low pulping efficiency and low pulp quality, so as to improve pulping efficiency, ensure homogenization, and accelerate The effect of debris decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

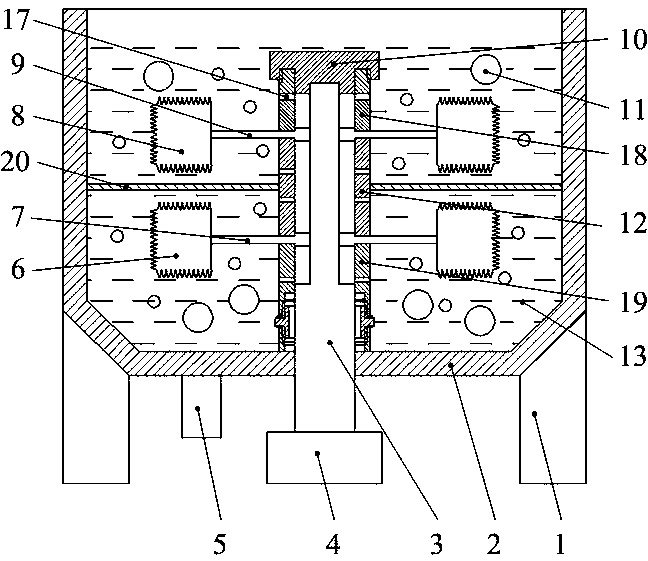

[0036] Such as figure 1 As shown, a kind of pulping equipment based on meandering-guided meandering type pulping of the present invention mainly includes a slurry generating device, a meandering guide device and a meandering pulping device, and the meandering guider is installed on the slurry generation In the device, the curved pulping device is installed on the curved guide device.

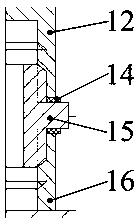

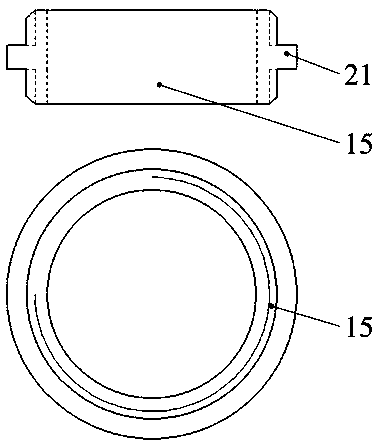

[0037]The slurry generating device is mainly composed of a material barrel 2, a slurry outlet 5 and a main shaft 3. The material barrel 2 is a cylindrical structure, and the material barrel 2 is filled with crushed material 11 and water 13. Cylinder 16, the outer side of the bottom of the material cylinder 2 is provided with a pulp outlet 5 and 4 circumferentially evenly distributed pillars 1, the main shaft 3 is installed in the middle of the material cylinder 2, and the main shaft 3 is arranged in the fixed cylinder 16, and the main shaft 3 is divided into two parts from top to bottom. The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com