High melt strength styrenic resin composition and preparation method thereof

一种苯乙烯类树脂、高熔体强度的技术,应用在高熔体强度苯乙烯类树脂组合物及其制备领域,达到厚度均匀、好加工性、降低生产难度和投资成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

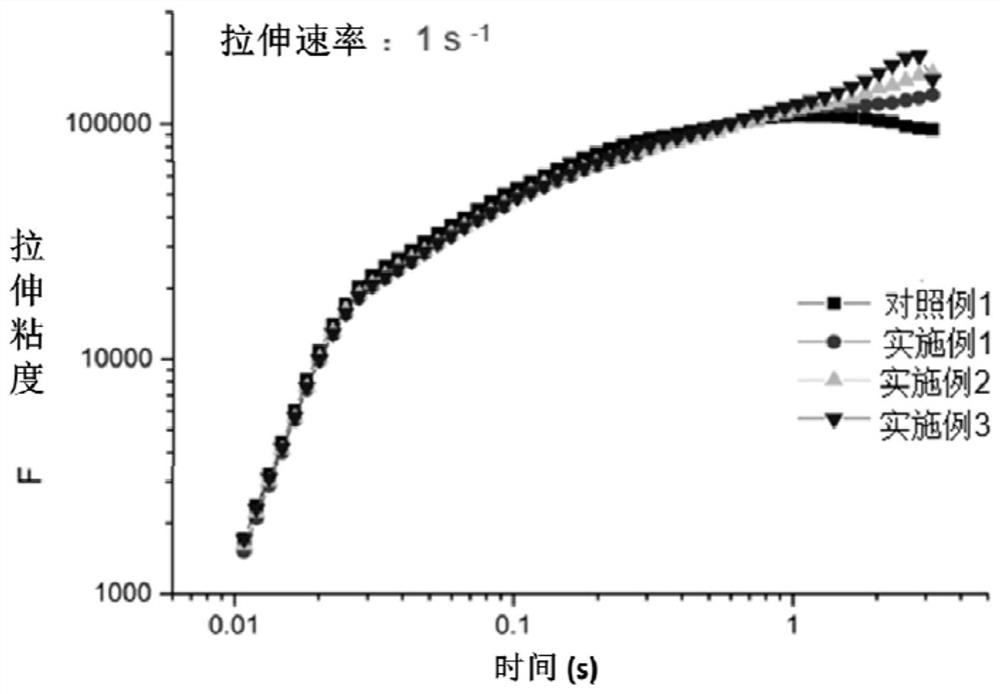

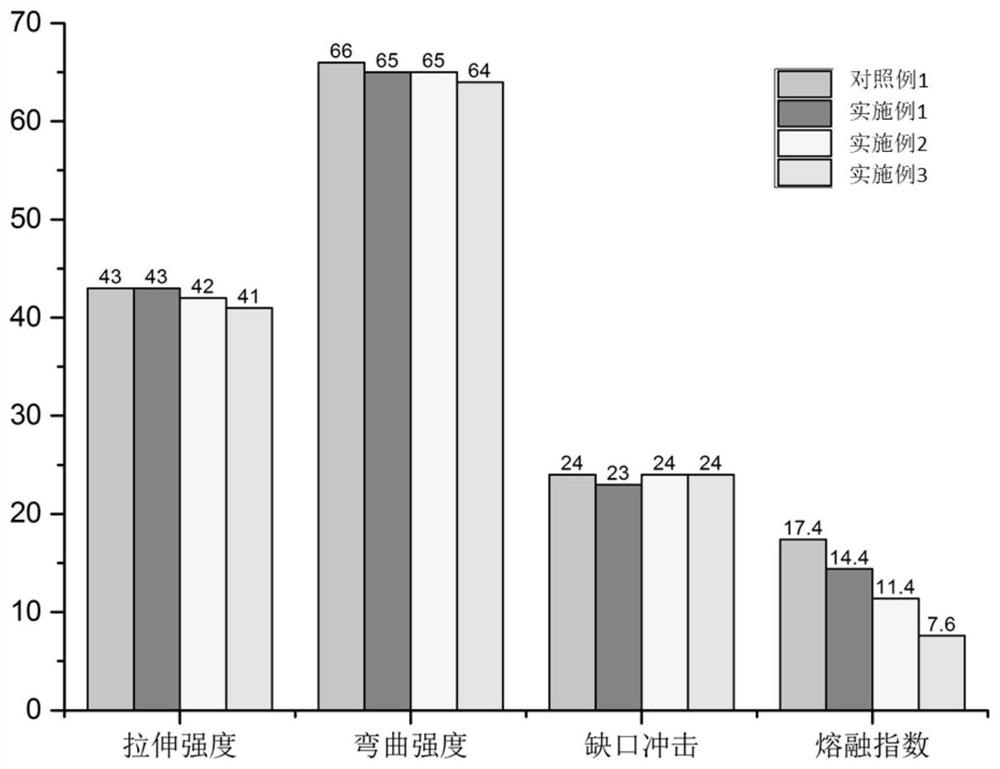

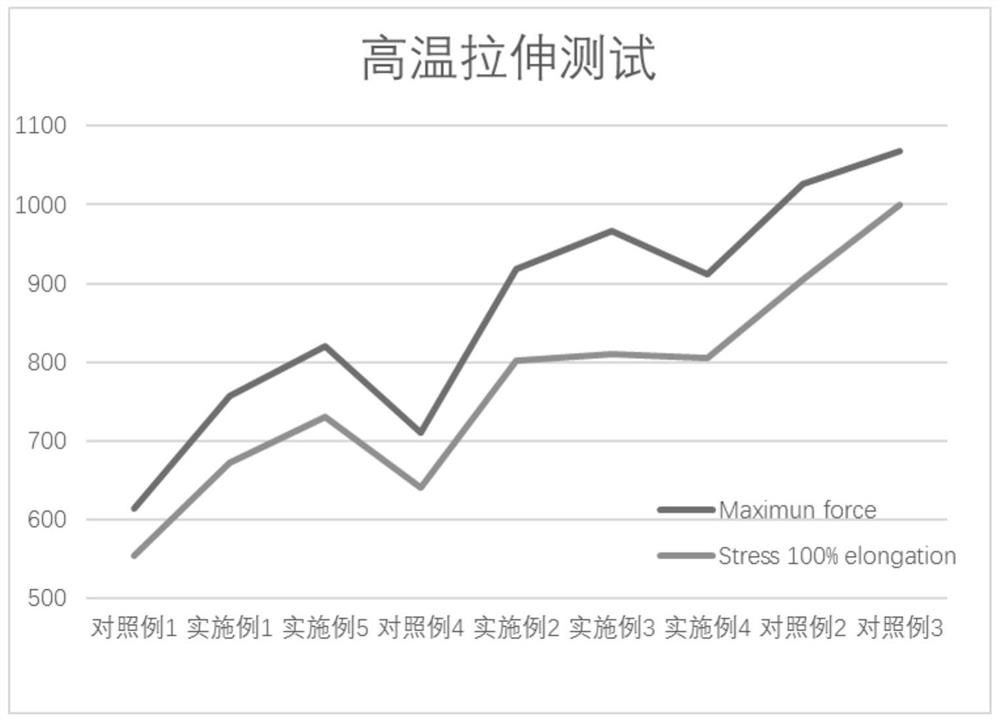

[0031] The formula table of table 1 embodiment and comparative example

[0032] Material Example 1 Example 2 Example 3 Example 4 Example 5 Comparative example 1 Comparative example 2 Comparative example 3 Comparative example 4 High rubber powder 180 50 50 50 50 30 50 50 50 30 AS-128L 50 50 50 50 40 50 50 50 50 PC 1100 30 30 Tackifier 10 20 30 20 10 50 70 TAF 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretching rate | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com