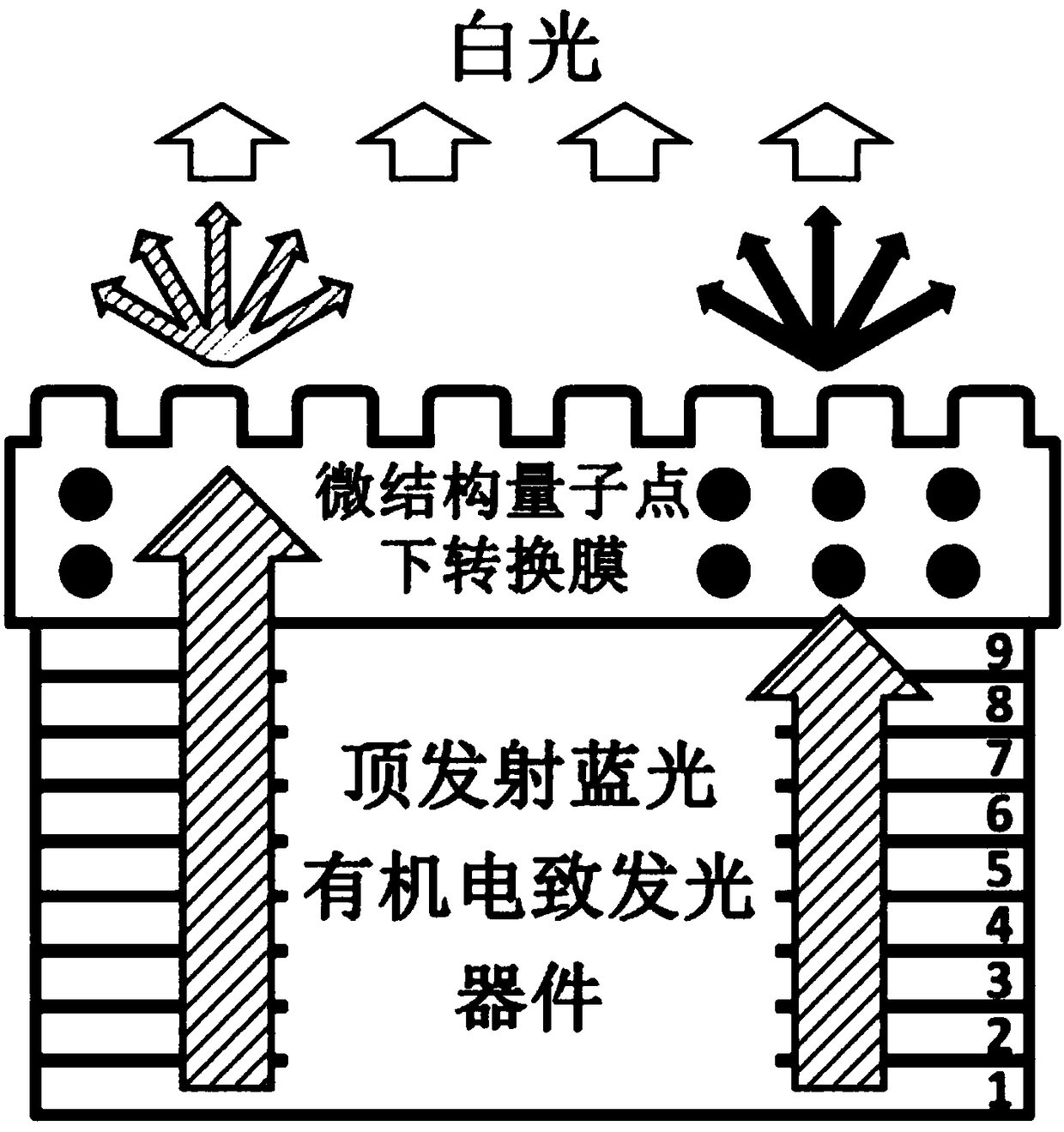

Top emitting white light organic electroluminescent device and its preparation method

An electroluminescent device, top emission technology, applied in the direction of electric solid device, semiconductor/solid-state device manufacturing, electrical components, etc. problem, to achieve the effect of improving light extraction, improving conversion efficiency, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

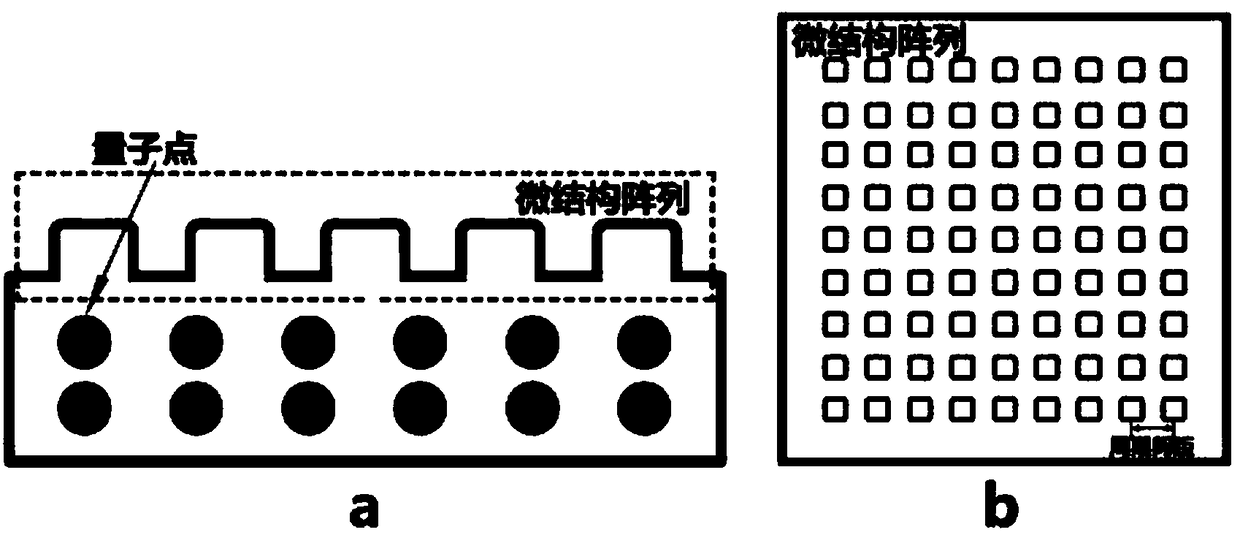

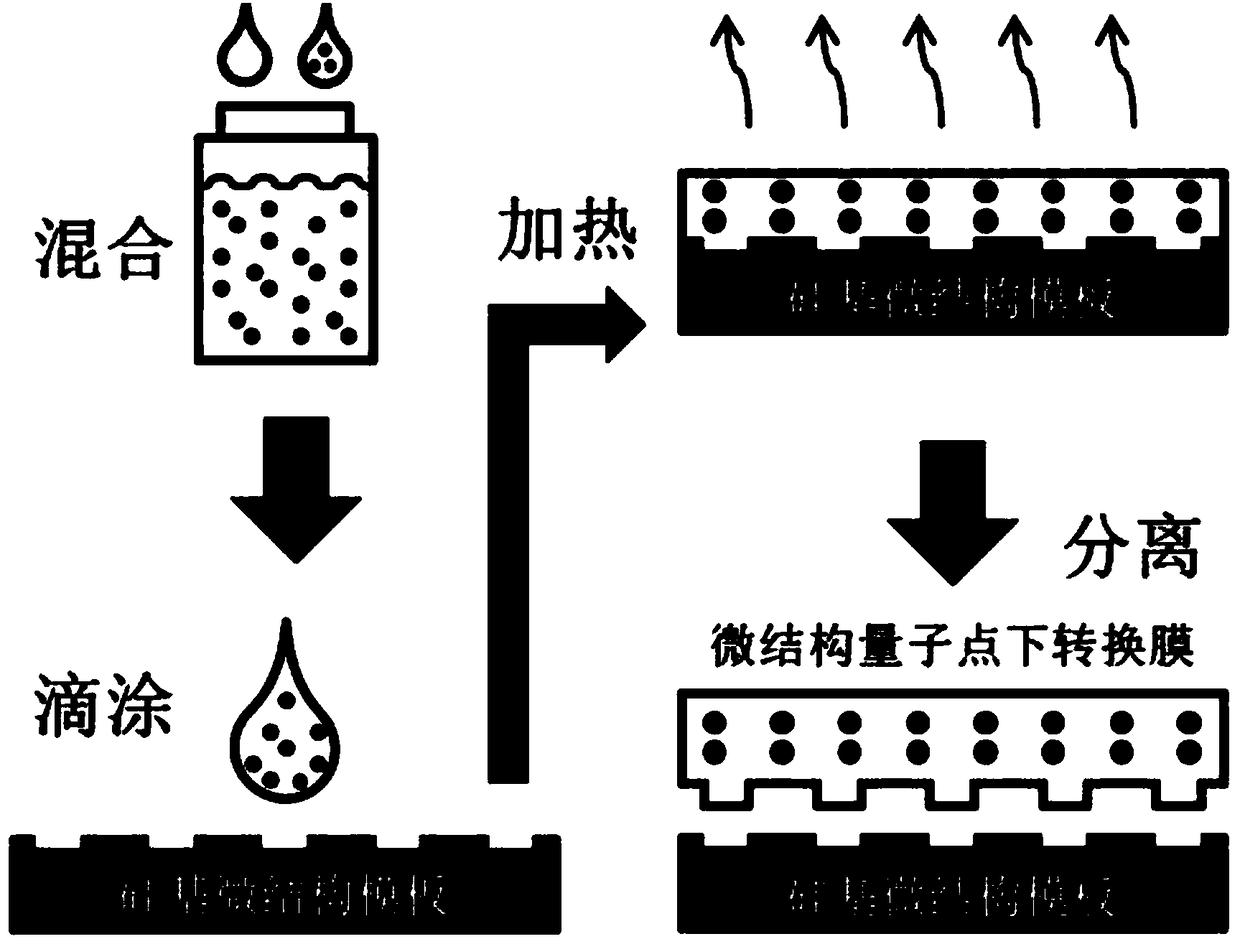

Embodiment 1

[0041] A microstructure quantum dot down-conversion film with a micro-cylindrical array on the surface was prepared by using a silicon-based microstructure template, with a thickness of 1 mm. Among them, CdSe / ZnS red light quantum dots with a light emission band of 630nm are used as the down-conversion material, and PMMA is used as the polymer host material. The microcolumns in the array have a diameter of 20 μm, a height of 5 μm, and a periodic pitch of 40 μm. Fabrication of Structure Glass Substrate / Ag(100nm) / MoO by Vacuum Evaporation 3 (3nm) / TAPC(40nm) / TCTA(5nm) / TCTA: Firpic(25nm) / TmPyPB(50nm) / Liq(2nm) / Sm(20nm) / TAPC(60nm) top-emitting blue light device, in which the light-emitting layer TCTA : The doping ratio of Firpic is 8:1. A top-emitting white light organic electroluminescent device is prepared by covering the microstructure quantum dot down-conversion film on the above-mentioned top-emitting blue light device. The detailed preparation process is as follows:

[004...

Embodiment 2

[0051] For comparison, a planarized quantum dot down-converting film was prepared using a common silicon wafer with a thickness of 1 mm and no pattern on its surface. CdSe / ZnS quantum dots with a luminescence wavelength of 630nm are used as the down-conversion material, and PMMA is used as the polymer host. The fabrication process of the planarized quantum dot down-conversion film is the same as that of the microstructure quantum dot down-conversion film in Example 1 except that the silicon-based template used is different. Prepare the same structure as glass substrate / Ag(100nm) / MoO by vacuum evaporation 3 (3nm) / TAPC(40nm) / TCTA(5nm) / TCTA: Firpic(25nm) / TmPyPB(50nm) / Liq(2nm) / Sm(20nm) / TAPC(60nm) top-emitting blue light device, in which the light-emitting layer TCTA : The doping ratio of Firpic is 8:1. A planarized quantum dot down-conversion film is covered on the top-emitting blue light device to prepare a top-emitting white light organic electroluminescent device. The detail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com