Tungsten diselenide and metal vertical schottky junction self-driven photoelectric detector and preparation

A photodetector, tungsten diselenide technology, applied in photovoltaic power generation, circuits, electrical components and other directions, can solve the problems of increased device cost, complex doping process, long response time, etc., to suppress reverse current, expand effective Lighting area, effect of suppressing increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

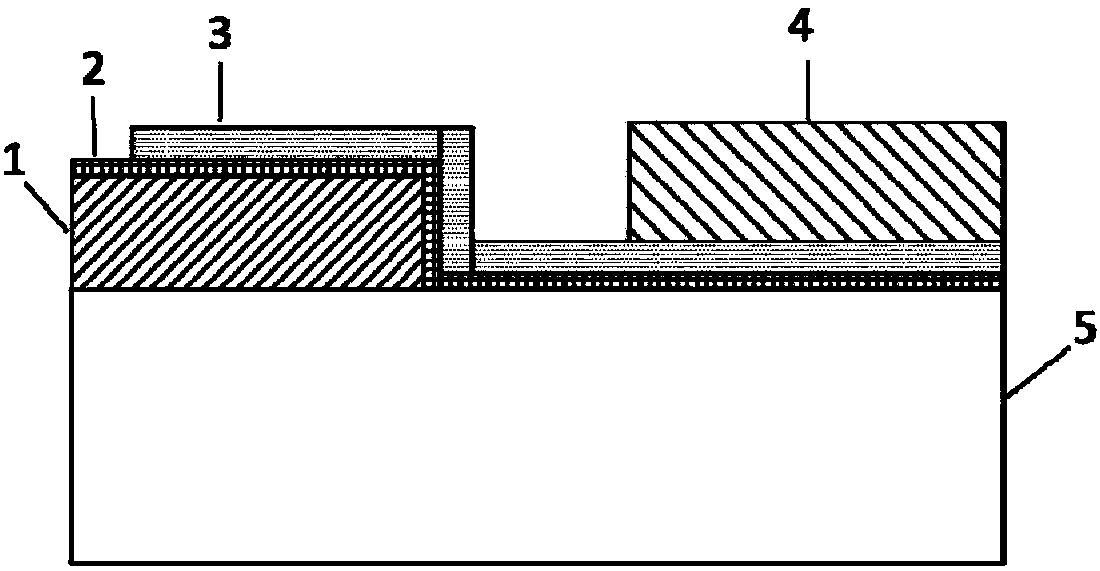

Embodiment 1

[0045] Tungsten diselenide and metal vertical Schottky junction self-driven photodetector, including source aluminum electrode, tunneling layer Al2O3, mechanically exfoliated 3nm thick tungsten diselenide, drain palladium electrode, insulating substrate silica. The aluminum electrode has a thickness of 20 nanometers; the aluminum oxide has a thickness of 0.5 nanometers; and the palladium electrode has a thickness of 30 nanometers. The specific preparation steps of the photodetector are as follows: first, put the insulating substrate silicon dioxide into three solutions of acetone, ethanol, and deionized water for 15 minutes, take it out, and dry it with nitrogen; then, use thermal evaporation or electron The aluminum electrode was evaporated on the silicon dioxide by beam evaporation; then, the tunneling layer aluminum oxide was deposited on the aluminum electrode by atomic layer deposition technology; again, the tungsten diselenide was transferred to the tunneling layer; fina...

Embodiment 2

[0047]Tungsten diselenide and metal vertical Schottky junction self-driven photodetector, including source aluminum electrode, tunneling layer Al2O3, mechanically exfoliated 1 nm thick tungsten diselenide, drain palladium electrode, insulating substrate silica. The titanium electrode has a thickness of 20 nanometers; the aluminum oxide has a thickness of 0.3 nanometers; and the palladium electrode has a thickness of 50 nanometers. The specific preparation steps of the photodetector are as follows: first, put the insulating substrate silicon dioxide into three solutions of acetone, ethanol, and deionized water for 15 minutes, take it out, and dry it with nitrogen; then, use thermal evaporation or electron The titanium electrode was evaporated on the silicon dioxide by beam evaporation; then, the tunneling layer aluminum oxide was deposited on the titanium electrode by atomic layer deposition technology; again, the tungsten diselenide was transferred to the tunneling layer; fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com