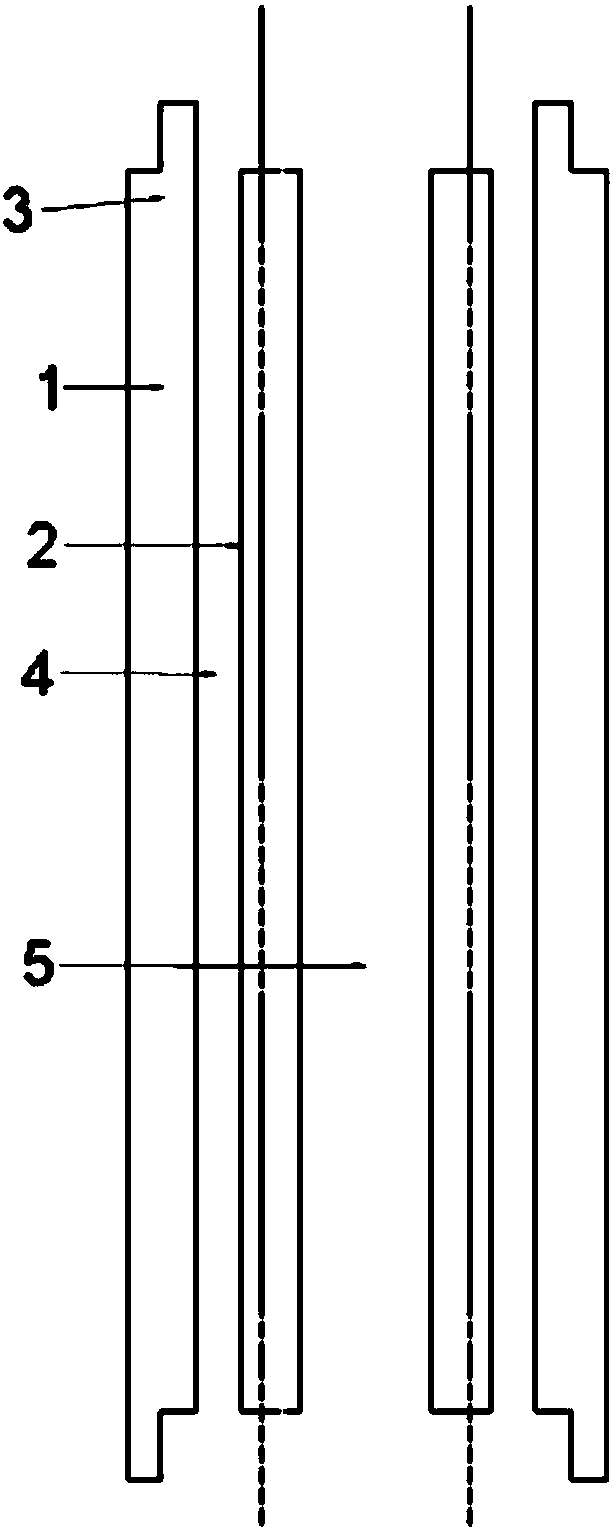

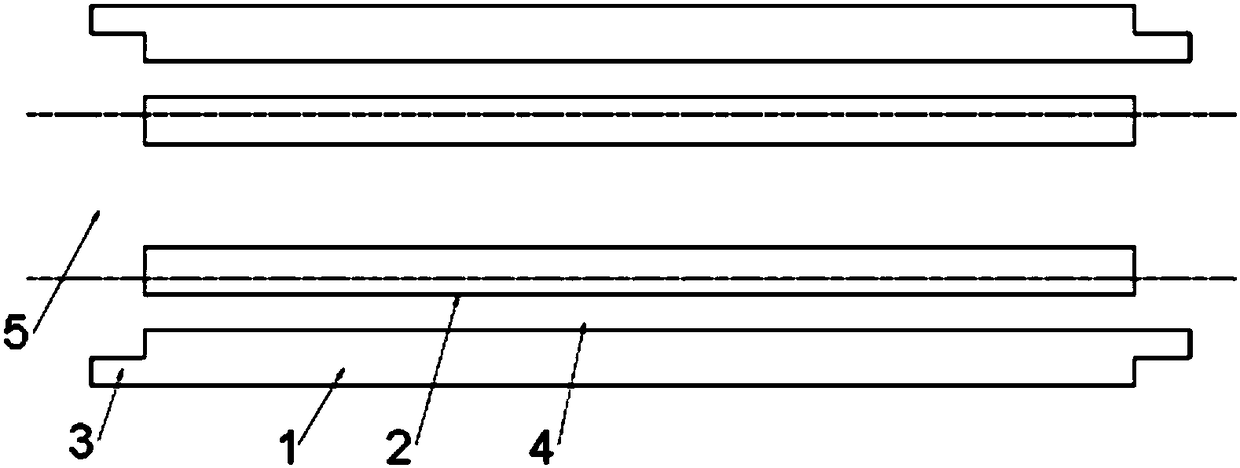

Cold area pipeline heat preservation system and testing method

A pipeline insulation and testing method technology, applied in pipeline protection, insulation, pipeline heating/cooling, etc., can solve the problems of unreliable fire insulation and difficulty in achieving expected results in tunnels in cold regions, so as to reduce energy consumption of insulation, facilitate installation and Maintenance and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0071] In order to achieve the above objectives, the implementation method of the cold zone pipeline insulation system of the present invention includes the following steps:

[0072] The first step is to investigate and investigate the on-site environmental temperature of the required insulation pipeline through field measurement and meteorological data investigation, and determine the law of environmental temperature changes along the pipeline layout direction. After investigating the temperature distribution in the direction of the pipeline, draw a temperature distribution map along the direction of the pipeline under extreme temperatures in order to determine the working range of the system; because the farther away from the opening in the tunnel and other underground spaces, the closer the temperature is to the annual average temperature. Not all pipe sections need insulation measures to avoid waste.

[0073] The second step is to calculate the heat loss in the air duct when di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com