System for rapidly recovering ammonia nitrogen in high ammonia nitrogen wastewater of livestock

A recycling system, high ammonia nitrogen technology, applied in animal husbandry wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of difficult cleaning, high cost, small applicability, etc. consumption, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

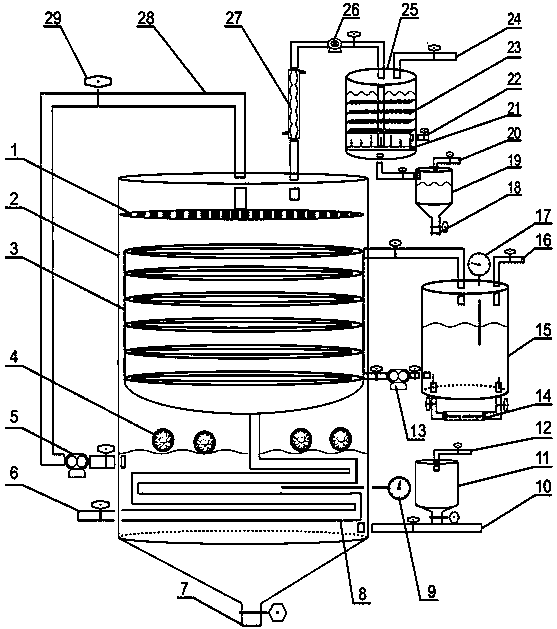

[0026] Example: Rapid ammonia nitrogen recovery system for pig wastewater.

[0027] 1) Pig wastewater flows into the wastewater tank through the inlet, and the volume of the wastewater is about 1 / 3 of the volume of the tank; and the pH value is adjusted to 10.0 by 2mol / L sodium hydroxide solution.

[0028] 2) Heat the water temperature of the pool to about 50°C through the heat exchanger, and send the hot water to the hot water pipe of the waste water tank through the water pump for recycling.

[0029] 3) The waste water is transported to the porous sprinkler (80 mesh) through the water pump, so that the generated water droplets collide with the hot water pipe, alternating cold and hot, and destroy the balance of ammonia in the water.

[0030]4) Use a vacuum pump to extract the ammonia gas released from the wastewater to improve the removal rate of ammonia gas.

[0031] 4) The high tower contains analytically pure phosphoric acid, the concentration of the magnesium chloride s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com