Cathode catalysis membrane coupled membrane-free microbial fuel cell for coking wastewater treatment system

A cathode catalysis and coking wastewater technology, which is applied in biochemical fuel cells, biological water/sewage treatment, electrochemical and biological combined treatment, etc., can solve problems such as poor water quality of microbial fuel cell effluent, difficult treatment of coking wastewater, complex process flow, etc. Achieve the effect of reducing process operation cost, improving effluent water quality and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

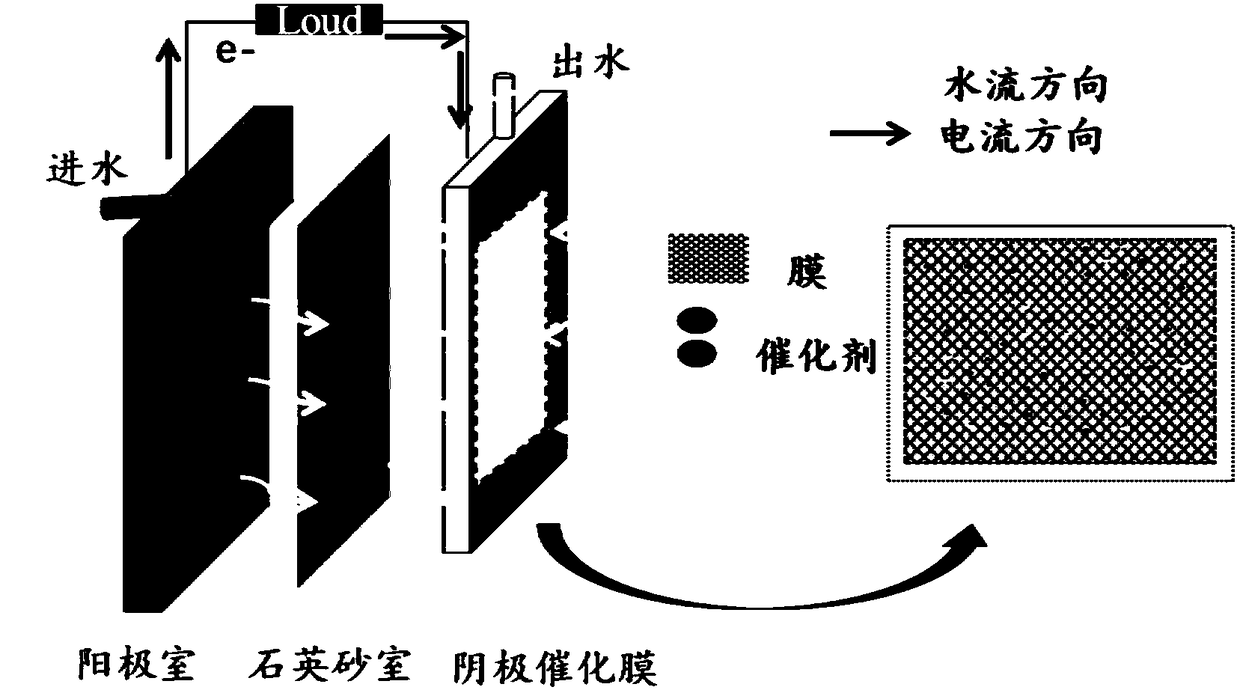

[0022] (1) Cathode TiO 2 / PVDF catalytic membrane preparation: TiO 2 (15wt%) and carbon nanofibers (25wt%) were added to PVDF (10wt%) DMF casting solution, after 6h stirring, ultrasonic degassing for 30min, carbon nanofiber cloth as substrate, coating thickness of 300μm, TiO is obtained after 12h phase transformation 2 / PVDF catalytic membrane cathode.

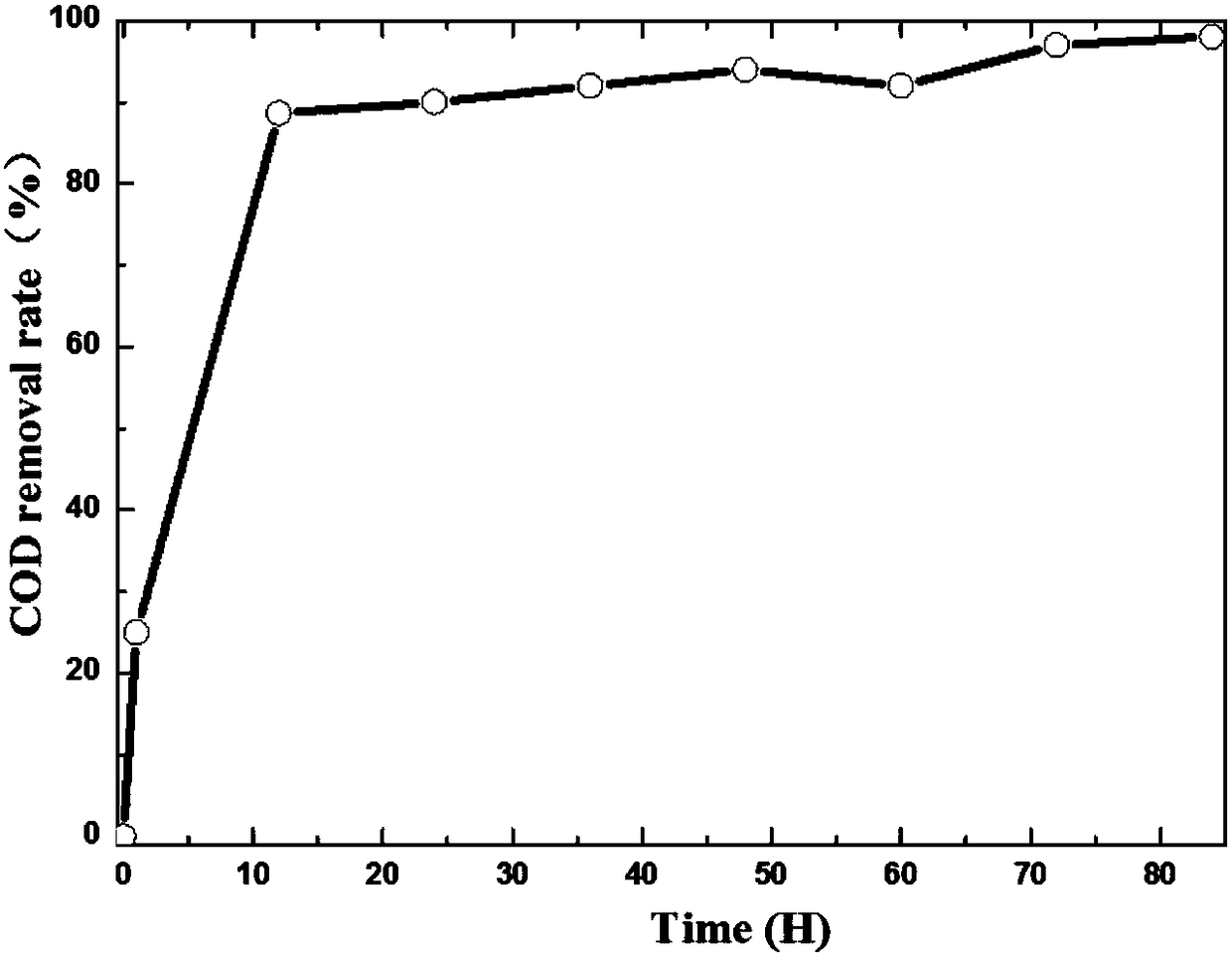

[0023] (2) Membrane-free microbial fuel cell coupled with cathode catalytic membrane system to treat low-concentration coking wastewater operation: the anode chamber is filled with activated carbon particles loaded with electricity-producing microorganisms (filling degree 85%), and the carbon rod is a conductive anode inserted into the activated carbon particles. Airtight low-concentration coking wastewater (COD about 200mg / L); the middle chamber filled with quartz sand between the two chambers replaces the proton exchange membrane; the above catalytic membrane is installed in a rectangular membrane module (double-sided), and the ...

Embodiment 2

[0025] (1) Cathode TiO 2 / Preparation of PVDF catalytic membrane: Same as described in Example 1.

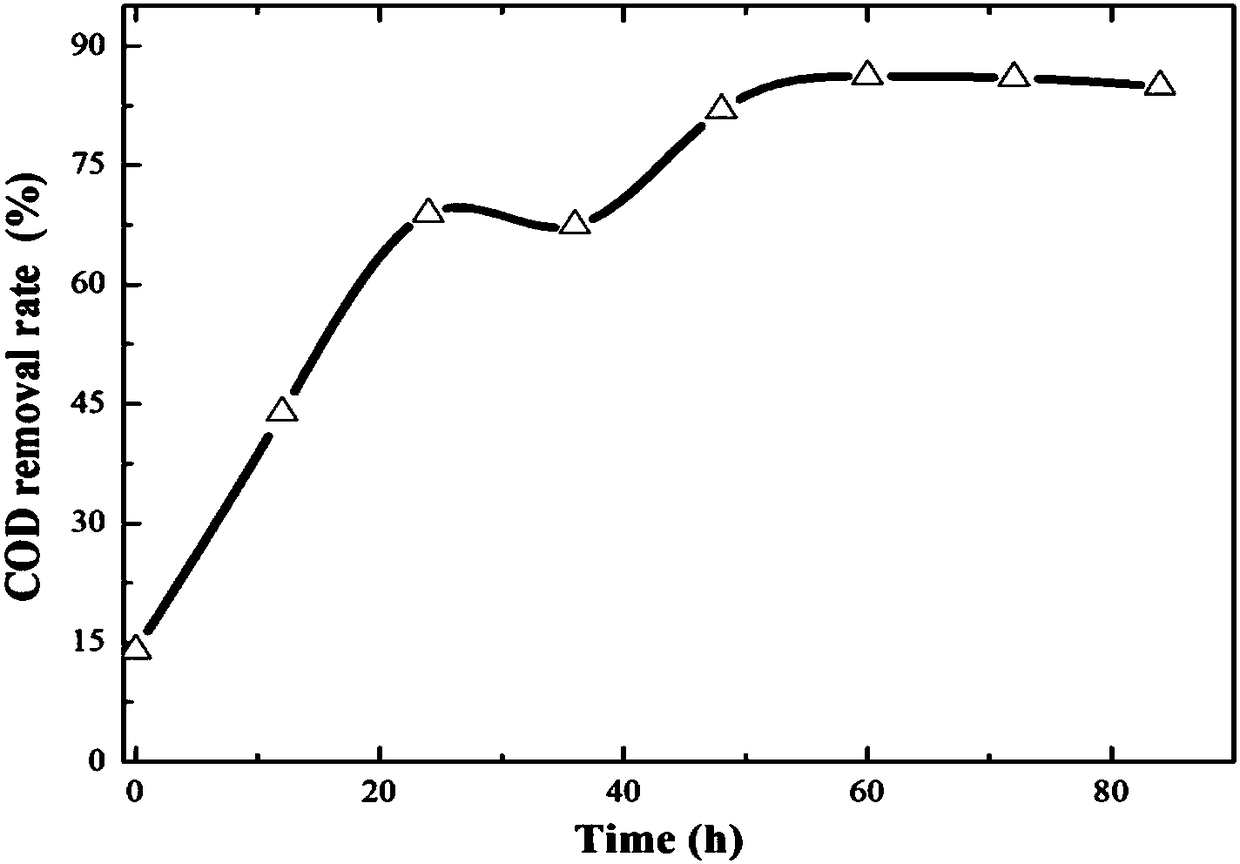

[0026] (2) Membrane-free microbial fuel cell coupled with cathode catalytic membrane system to treat high-concentration coking wastewater operation: the anode chamber is filled with activated carbon particles loaded with electricity-producing microorganisms (filling degree 85%), and the carbon rod is a conductive anode inserted into the activated carbon particles. Airtight low-concentration coking wastewater (COD about 2000mg / L); the middle chamber filled with quartz sand between the two chambers replaces the proton exchange membrane; the above-mentioned catalytic cathode membrane is installed in a rectangular membrane module (double-sided), and the bottom of the cathode chamber is exposed Air provides oxygen for electronic activation of oxygen to generate free radicals; the water from the top of the cathode membrane module is pumped by a pump, and the anode and cathode are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com