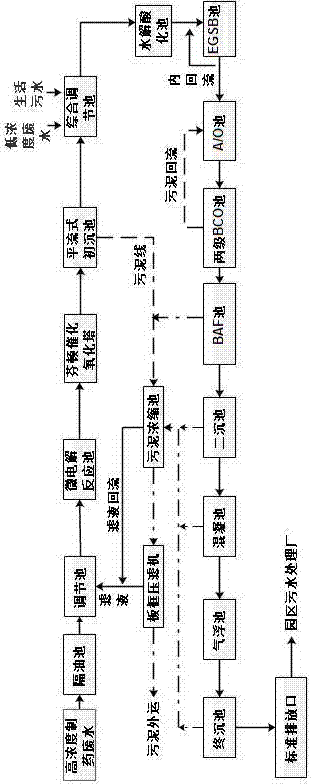

Pharmaceutical wastewater technology using microelectrolysis-Feton-EGSB (expanded granulate sludge bed)-A/O (anaerobic/aerobic)-BCO (biological contact oxidizing)-BAF (biological aeration filtering)-coagulation treatment

A technology of pharmaceutical wastewater and micro-electrolysis, applied in the field of environmental science and engineering, can solve the problems of high operating costs and difficult discharge standards, and achieve the effects of reducing treatment load, increasing concentration and saving pharmaceutical costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The processing capacity is 300m 3 / d of pharmaceutical wastewater (50t / d for high-concentration wastewater, 200t / d for low-concentration wastewater, and 50t / d for domestic sewage), among which the quality of high-concentration wastewater: CODCr 85000~90000mg / L, NH 3 -N 150~200mg / L, TP70~100mg / L, pH 3~6mg / L. Low concentration wastewater quality: CODCr 7000~8000mg / L, NH 3 -N 120~150mg / L, TP 30~50mg / L, pH 3~8mg / L. Domestic sewage water quality CODCr 200~400mg / L, NH 3 -N 20~30mg / L, TP 3~5mg / L, pH 7~8mg / L. The high-concentration pharmaceutical wastewater passes through the grease trap and regulating tank in turn to remove floating oil and adjust the water quality and quantity, and then is lifted by the lift pump to the iron-carbon micro-electrolytic pool. The iron-carbon electrolytic cell uses the acidity of wastewater and the potential difference between iron-carbon particles to form countless tiny primary cells to produce electrochemical reactions, and under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com