Intelligent visual flexible line system based on industrial robot

An industrial robot and intelligent vision technology, applied in the field of intelligent vision flexible line system, can solve problems such as poor flexibility, waste of manpower and material resources, and poor scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

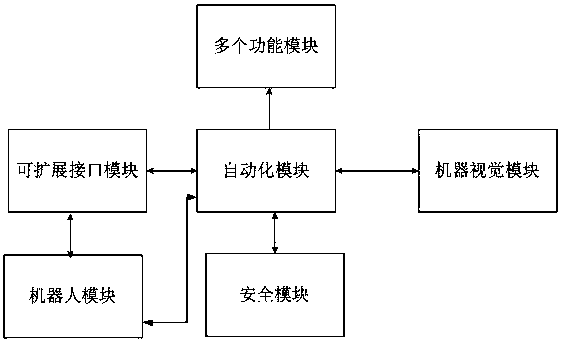

[0017] Those skilled in the art understand that, as mentioned in the background technology, the traditional industrial robot application in the prior art can only be customized for each product for robot motion trajectory and robot control program, and cannot adapt to changes in automated assembly lines. Robots have poor scalability and flexibility, and can only be specially made for special needs, which greatly wastes manpower and material resources. The present invention provides an intelligent vision flexible line system based on industrial robots to solve the above problems, which is convenient for customers to carry out secondary development, teaching and research and other purposes. In order to make the above objects, features and beneficial effects of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] figure 1 It is a structural diagram of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com