Casting method for preventing shrinkage porosity at thick large wall of casting

A technology for castings and defects, which is applied in the casting field to prevent shrinkage and porosity defects at thick and large walls of castings. Light weight, large heat capacity ratio, and the effect of solving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

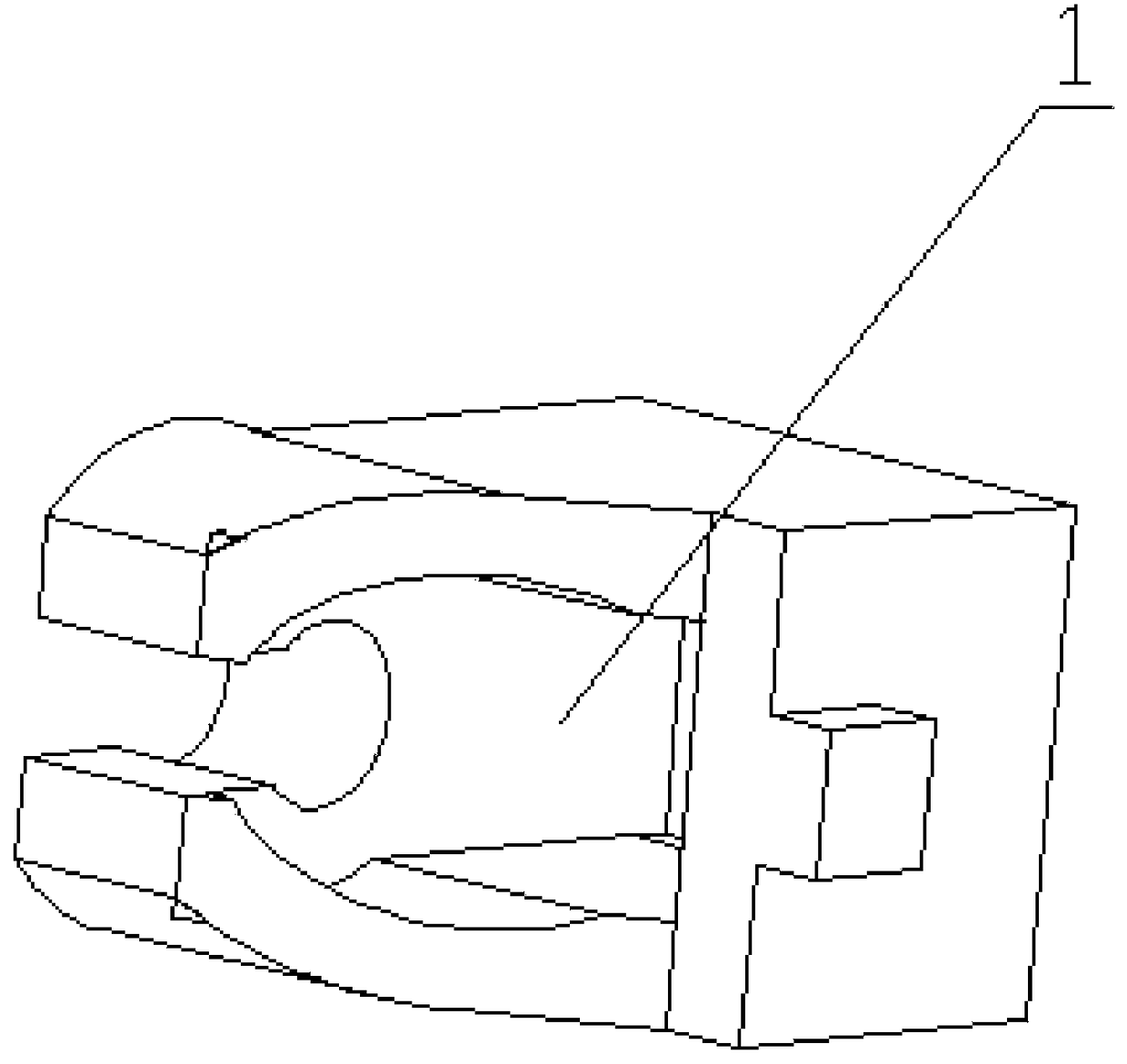

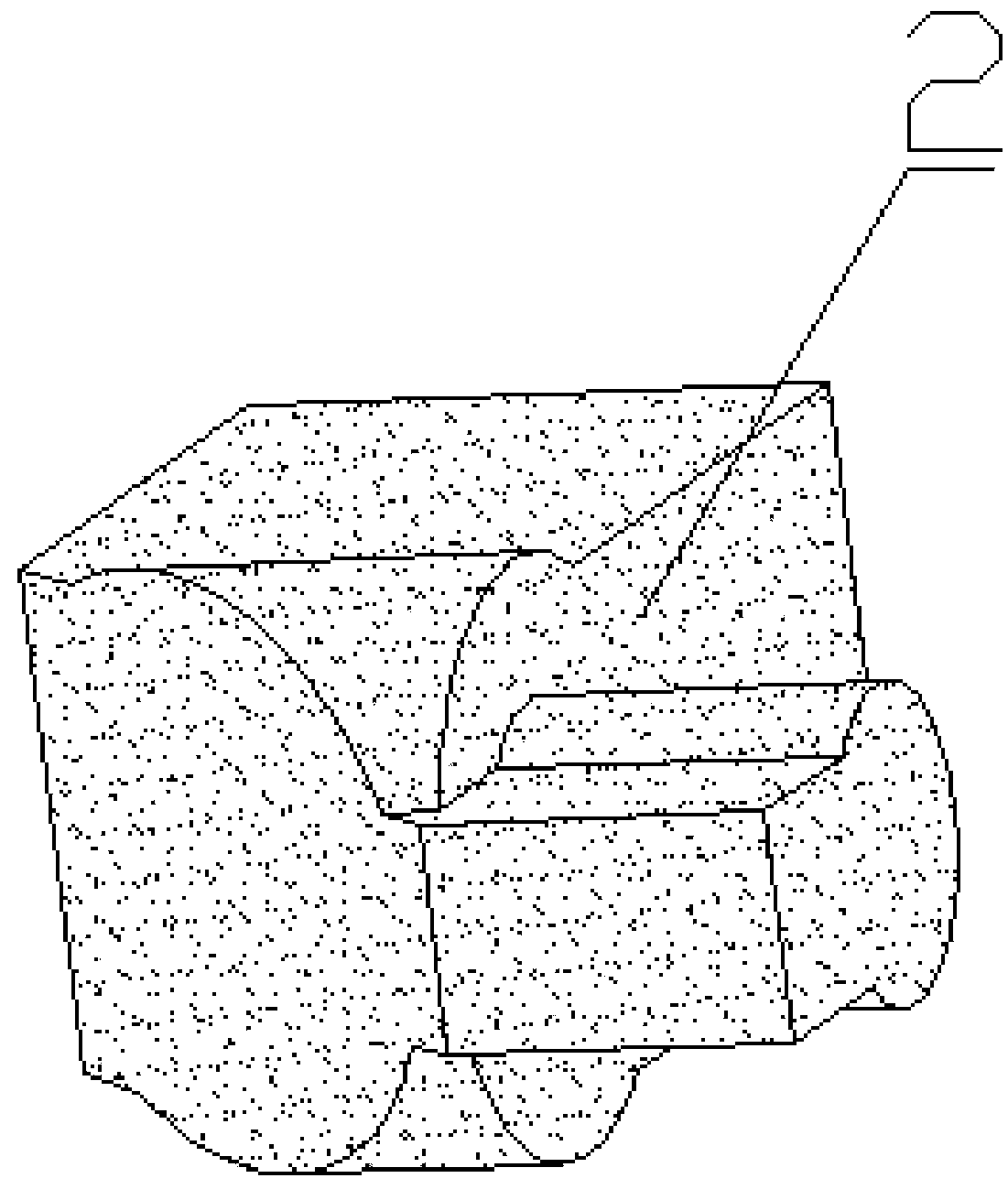

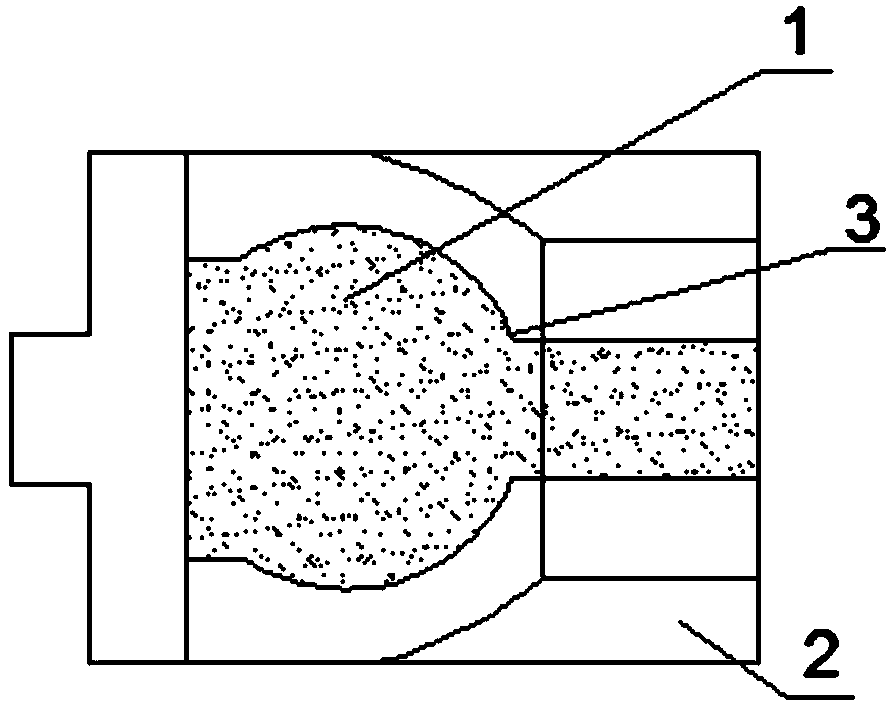

[0022] Such as Figure 1 to Figure 3 As shown, a casting method to prevent shrinkage and porosity at the thick and large wall of the casting. The casting method adopts the lost foam casting process, and the molding process adopts the vacuum negative pressure molding method. The cold iron of the chilling material is placed at the corresponding position of the lost pattern according to the requirements of the casting process, and the cold iron and the lost pattern are bonded together. The light chilling material is graphite.

[0023] When the thick and large wall of the casting is the jaw structure 1, graphite is selected as the light chilling material, and it is designed as a jaw graphite chiller 2 structure that fits with the jaw structure 1, and the jaw graphite chiller 2 and the corresponding After assembling the jaw structure 1 of the lost pattern shape, use hot melt adhesive 3 to bond the gap between the jaw graphite cold iron 2 and the lost pattern shape. After the hot me...

Embodiment 2

[0025] Such as Figure 4 to Figure 6 As shown, when the thick and large wall of the casting is a planar structure 4, graphite is selected as a light chilling material, and it is designed as a rectangular graphite chiller 5 structure. After applying and drying the lost foam pattern in sequence, the rectangular graphite The cold iron 5 is placed on the thick and large-walled planar structure 4 of the lost foam pattern according to the requirements of the casting process, and the cold iron and the lost foam pattern are bonded with the sand mold adhesive 6, and the sand mold adhesive 6 is hardened and molded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com