Graphene variable current electrothermal film

A variable current, graphene technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts and other directions, can solve the problems of safety hazards, high resistance of carbon strips, and easy to cause serious consequences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

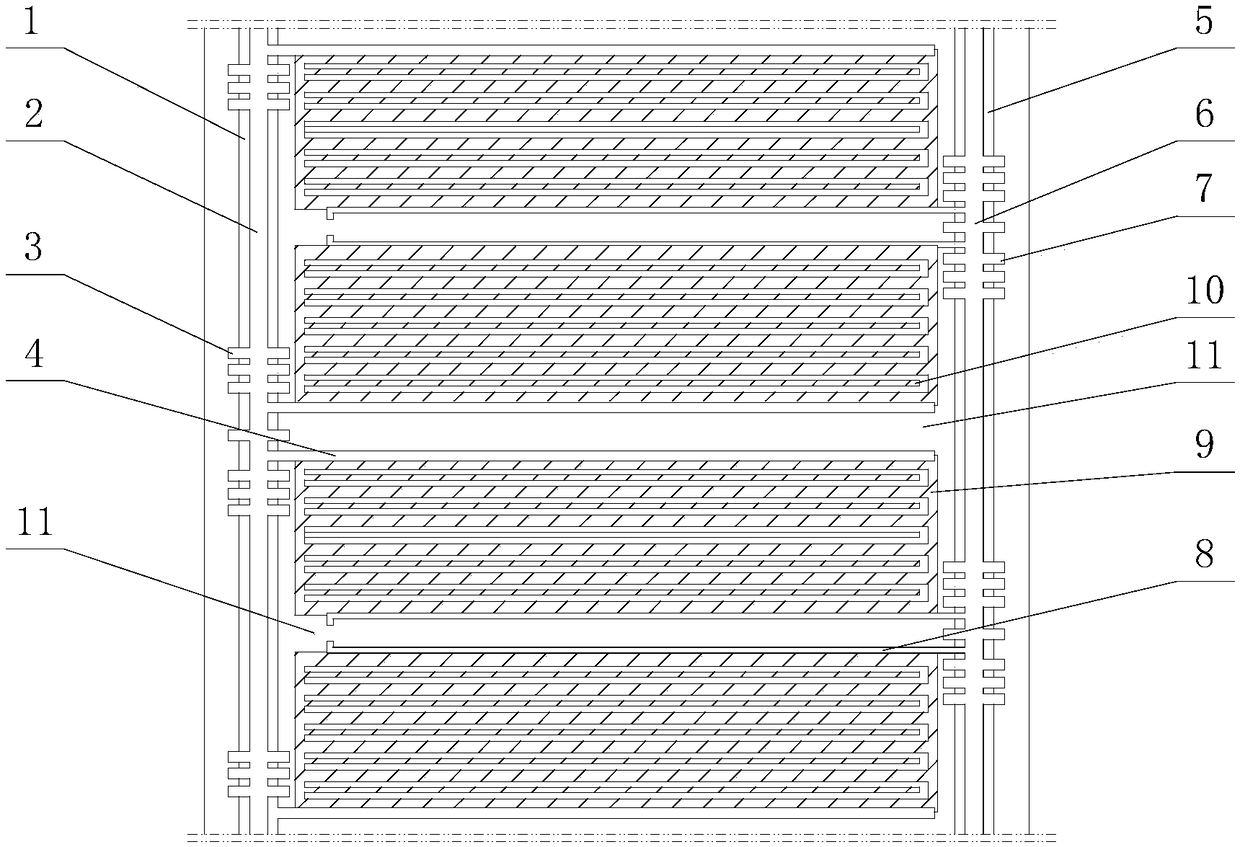

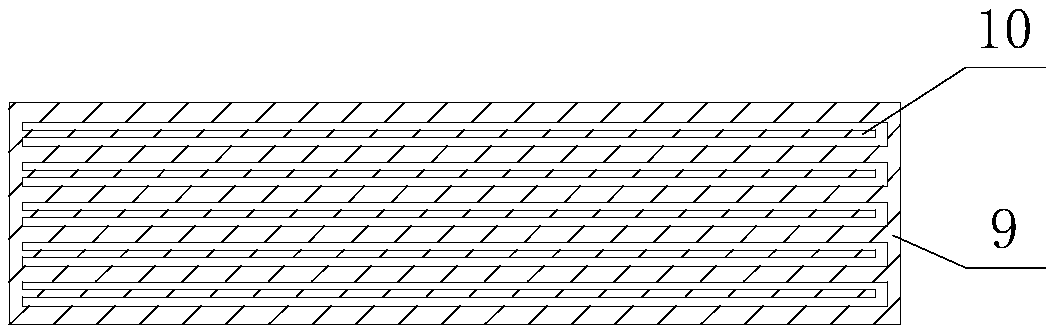

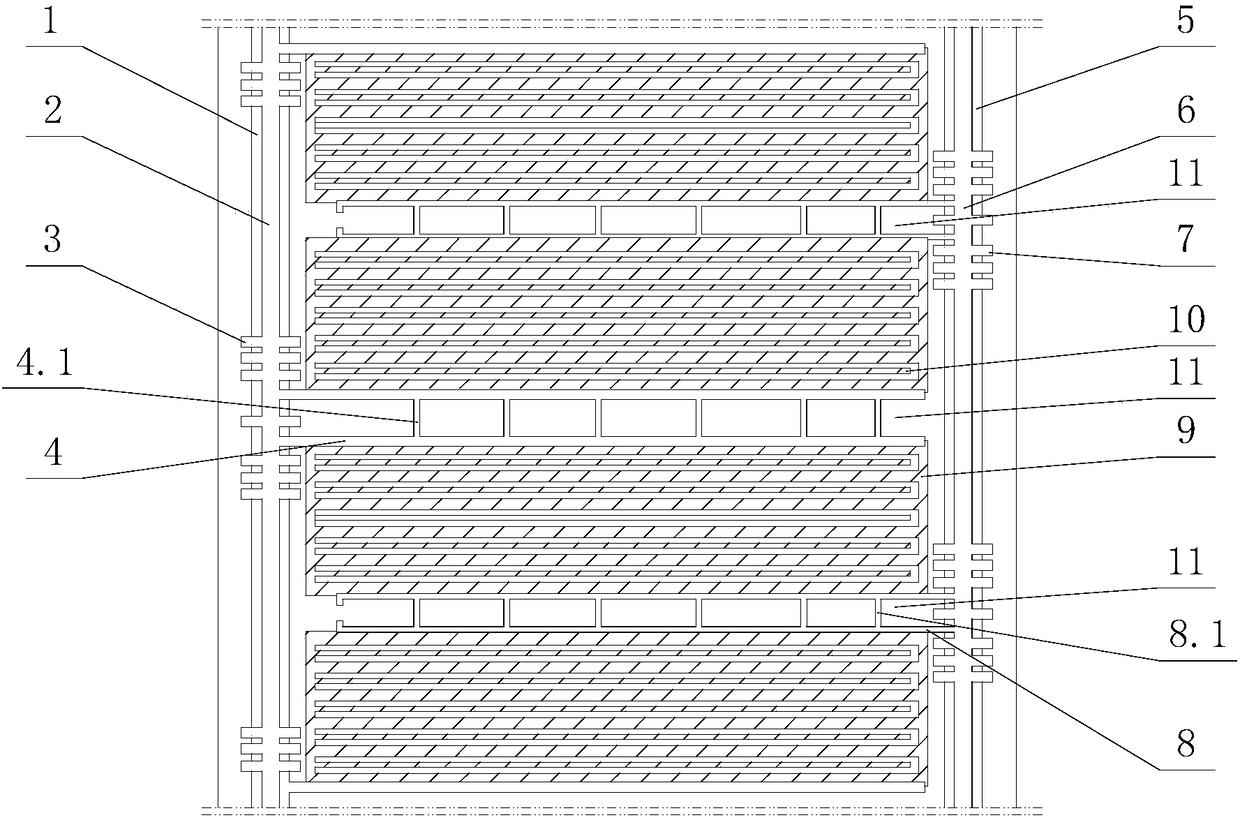

[0044] see Figure 1-Figure 3 , the graphene variable current electric heating film, the graphene variable current electric heating film includes a heating unit, each heating unit includes a carbon heating area 9 and a silver paste current-carrying bar arranged on the first base film, and is arranged on the For the copper foil busbar on the second base film, the carbon heating zone 9 is arranged in the middle of the first base film, and the silver paste busbar is arranged around the carbon heating zone 9 and is electrically connected to the carbon heating zone 9; The first base film is covered on the second base film, the copper foil current carrying bar is crimped on the silver paste current carrying bar and is electrically connected with the silver paste current carrying bar, and the copper foil current carrying bar is arranged on both sides of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com