Electric wheelchair hub motor

A hub motor and electric wheelchair technology, which is applied in the direction of electric components, brake actuators, gear transmission mechanisms, etc., can solve the problems of inability to guarantee the mechanical brake mechanism, inconvenient movement, and inappropriateness, and achieve simple manufacturing, convenient processing, and small size. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

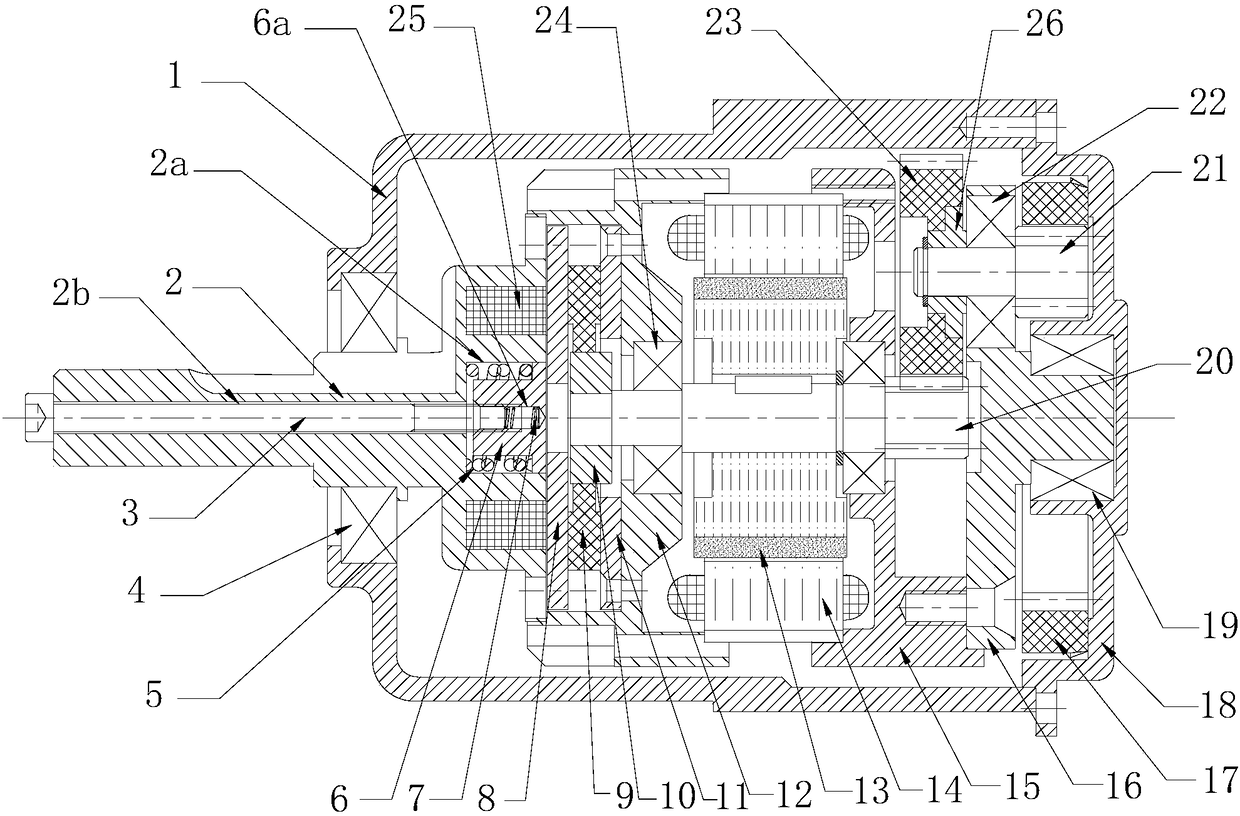

[0029] Example: Combined figure 1 The hub motor of this electric wheelchair provided by the present invention is described in detail as follows:

[0030] This electric wheelchair hub motor has a large shaft 2 fixed to the wheelchair bracket, a hub body mounted on the shaft 2 through a shaft bearing 4 rotation, a motor body and a planetary reduction mechanism arranged in the hub body, and the motor body It includes the motor casing fixed to the inner end of the large shaft 2, the stator and rotor 14, 13 arranged in the motor casing, and the output shaft fixed to the rotor 13 and protruding from the motor casing. The output shaft is connected to the wheel hub through the planetary reduction mechanism The inner ring gear 17 on the inner wall of the body is connected in transmission.

[0031] Specifically, such as figure 1 As shown, the hub body in this embodiment includes a hub shell 1 and a hub end cover 18 fixed to the hub shell 1. The hub shell 1 is rotatably assembled on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com