Full recovery process and control method of converter steelmaking gas based on nitrogen compensation

A technology of converter steelmaking and full recovery, which is applied in metal processing, waste gas treatment, manufacturing converters, etc., and can solve unseen problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

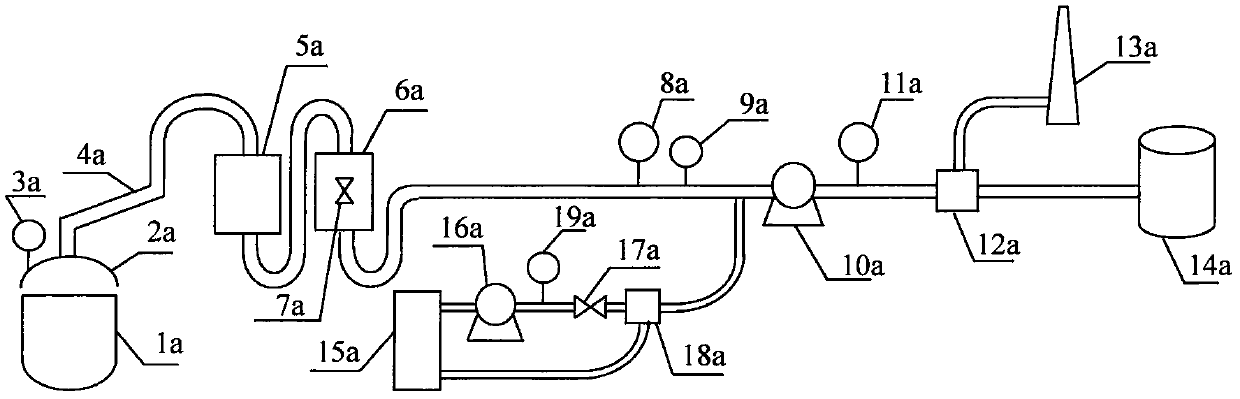

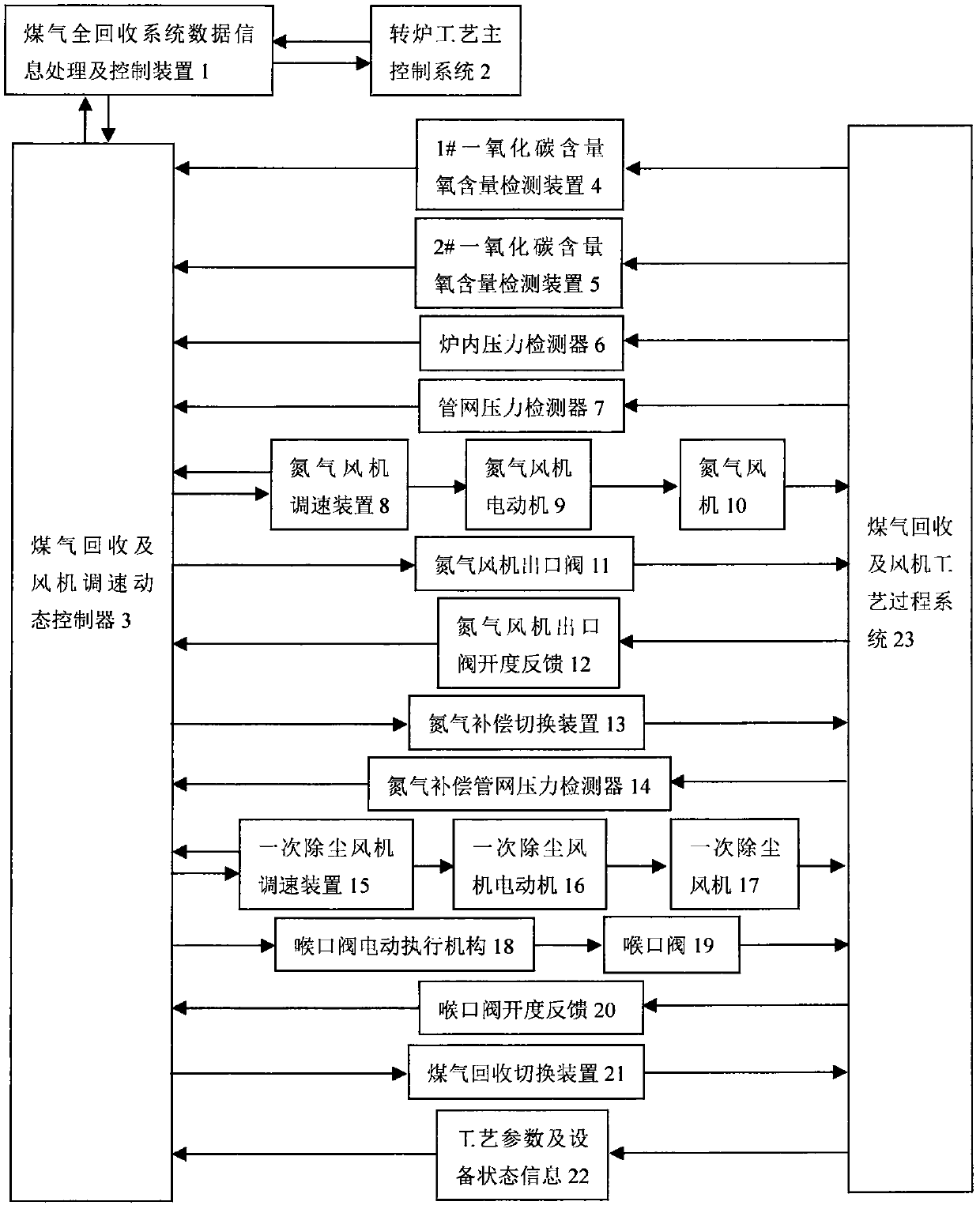

Embodiment Construction

[0012] Regarding the analysis of the current coal gas recovery situation, the general recovery conditions currently used are CO content ≥ 35% and oxygen content ≤ 2%. The process associated with gas recovery is usually divided into three stages in the converter smelting process, called the pre-combustion period. , Gas payback period and post-burn period. Taking a 120-ton converter as an example, the converter smelting cycle is about 35-40 minutes, of which the oxygen blowing smelting time is about 15 minutes, divided into the pre-burning period about 3 minutes, the gas recovery time about 10 minutes, and the post-burning period about 2 minutes; non-smelting time About 20-25min. In other words, the current gas recovery time is about 10 minutes, and the gas is not recovered at the time of about 3 minutes in the pre-burning period and about 2 minutes in the post-burning period, but is ignited and released through the chimney. The reason why the gas in the pre-burning period is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com