Method for preparation of organic calcium nutrient soil by municipal sludge

A technology of municipal sludge and organic calcium, which is applied in the fields of organic fertilizer, sewage/sludge fertilizer, dehydration/drying/concentrated sludge treatment, etc., to achieve the effect of good nutrient soil quality, low cost and little secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

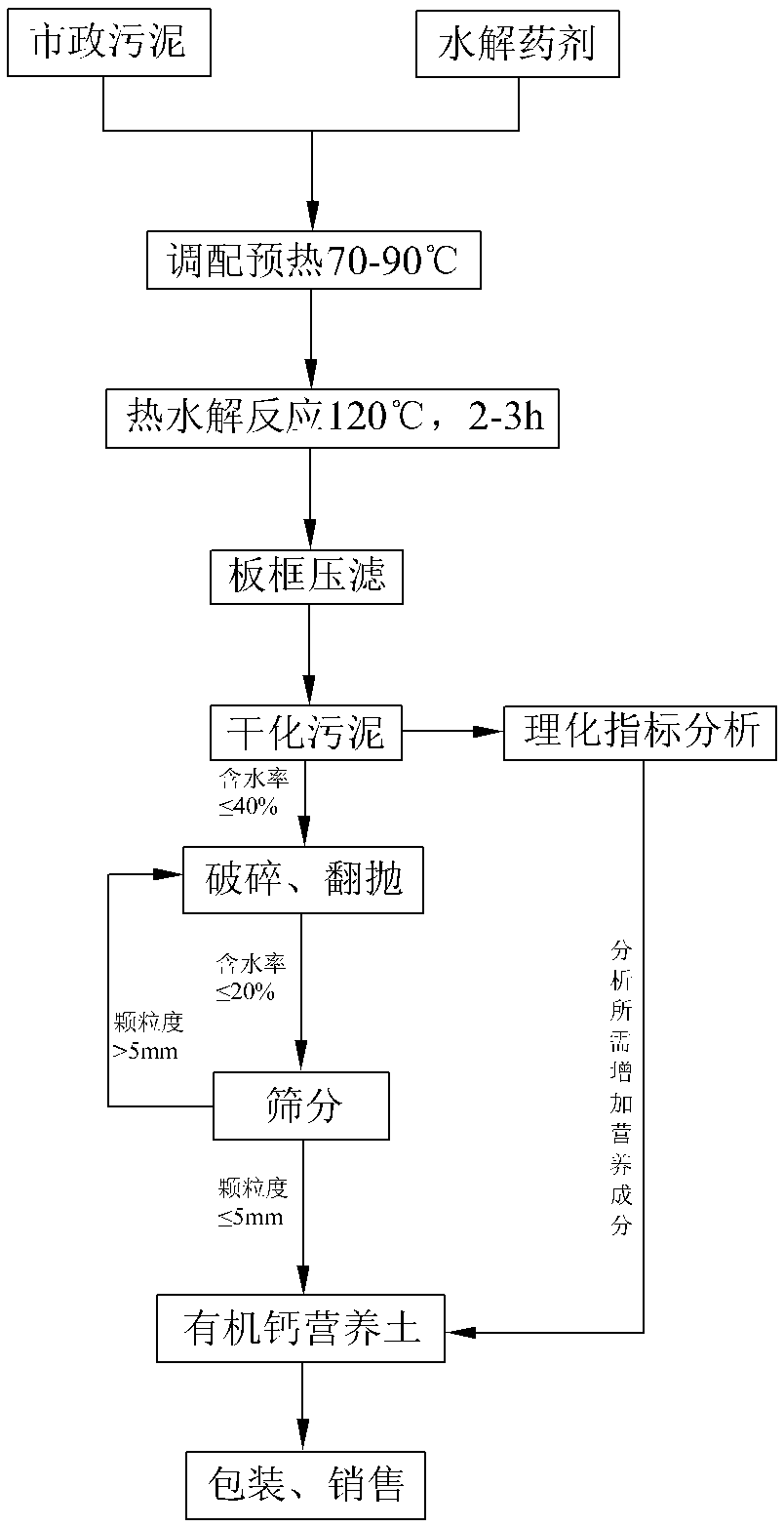

[0021] Such as figure 1 Shown, a kind of method that municipal sludge prepares organic calcium nutrient soil:

[0022] (1) After the municipal sludge (collected from Shanxi Sewage Treatment Co., Ltd.) is collected, it is prepared together with the hydrolysis agent and preheated to 70°C, and the thermal hydrolysis reaction is carried out at a temperature of 123°C, and the temperature is kept at 123°C for 3 hours; The hydrolysis agent is quicklime, and the proportion of quicklime added is 20% of the dry weight of the sludge; after the thermal hydrolysis treatment, the municipal sludge will destroy the microbial cell wall, and release the protein and water in the bacteria gelatin, which is convenient for step (2) pressing and dehydration.

[0023] (2) After thermal hydrolysis treatment, the treated municipal sludge directly enters the plate-and-frame filter press without adding any conditioning agents, and is squeezed through the plate-and-frame filter press to obtain a moisture ...

Embodiment 2

[0030] The difference between the method of Example 2 and the method of Example 1 is that the addition ratio of quicklime is 22.5% of the dry weight of the sludge, the deployment preheating temperature is 90°C, the thermal hydrolysis reaction temperature is 120°C, and a constant temperature of 120°C is maintained for 2 Hour.

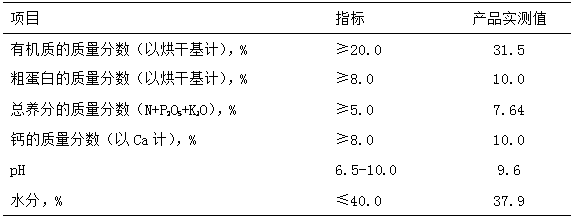

[0031] In step (3), the moisture content of the dried sludge is 38.2%, the pH value is 9.8, the calcium content is 11.3%, the organic matter content is 32.5%, the crude protein content is 10.3%, and the total nutrient content is 7.73%, which meet the standard requirements.

Embodiment 3

[0033] The difference between the method of Example 3 and the method of Example 1 is that the addition ratio of quicklime is 18% of the dry weight of the sludge, the deployment preheating temperature is 80°C, the thermal hydrolysis reaction temperature is 125°C, and the constant temperature of 125°C is kept at 2.5°C. Hour.

[0034] In step (3), the moisture content of the dried sludge is 39.0%, the pH value is 8.6, the calcium content is 9.4%, the organic matter content is 30.9%, the crude protein content is 9.8%, and the total nutrient content is 7.52%, which meet the standard requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com