Thermomagnetic device for spray molding of decorative balls

A decorative ball and plastic spraying technology, which is applied in the direction of spraying devices, electrostatic spraying devices, spray booths, etc., can solve the problem that the thickness of the paint layer on the surface of the magnetic decorative ball is difficult to ensure uniformity, the thickness of the surface paint layer is difficult to ensure uniformity, and the consumption of plastic powder is large. And other problems, to achieve the effect of easy to ensure uniform thickness of surface paint layer, wide range of weight, and small consumption of plastic powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

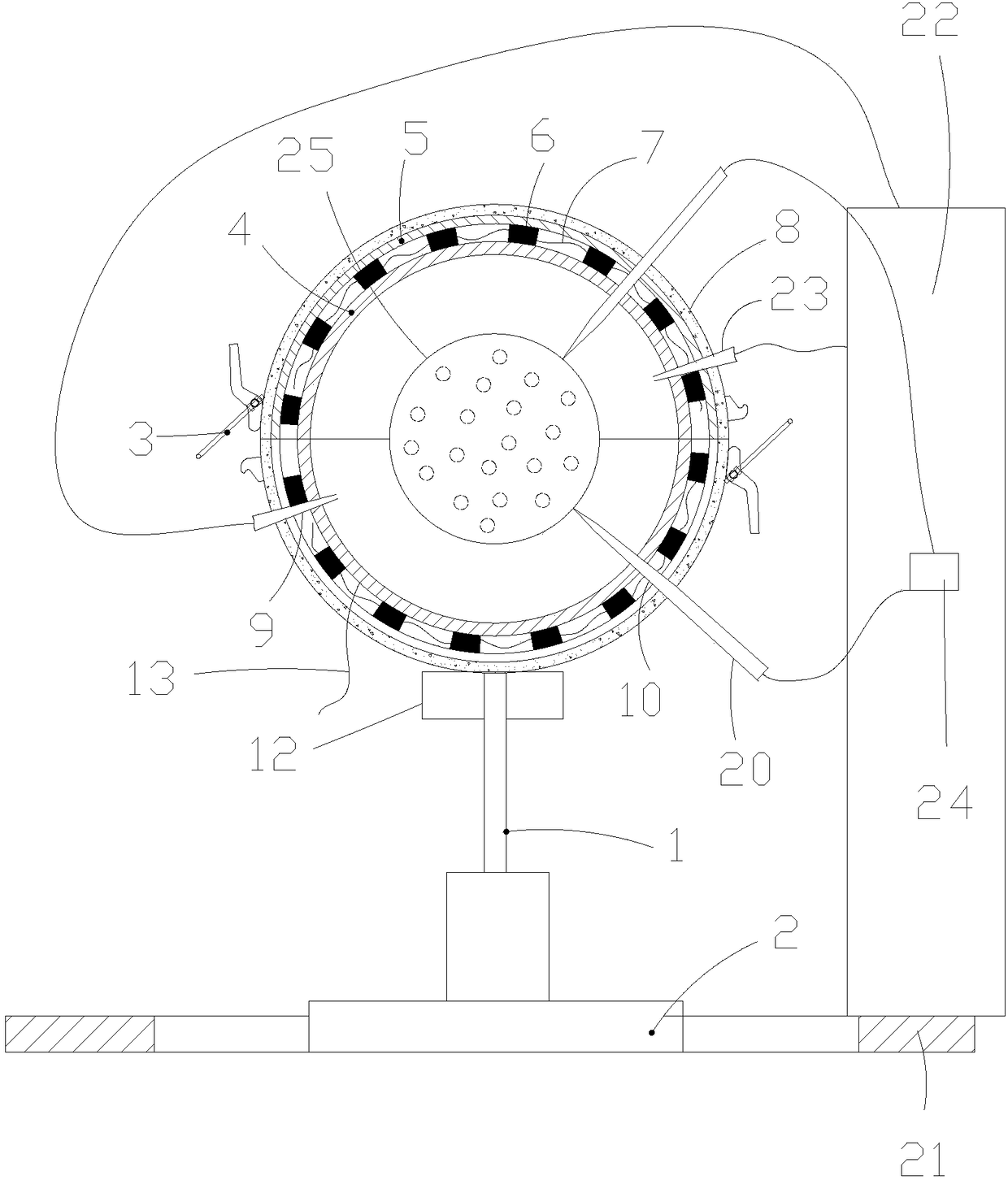

[0014] Example. A thermal-magnetic device for spraying decorative balls, comprising a hollow sphere, a bottom plate 2 is arranged below the hollow sphere, a motor 1 is arranged on the bottom plate 2, the output shaft of the motor 1 is connected with the hollow sphere, and the hollow sphere is composed of upper and lower hemispheres The two shells are connected by a quick lock 3. The shell includes an inner shell 4 and an outer shell 5. A plurality of evenly distributed magnets 6 are arranged between the inner shell 4 and the outer shell 5. , a heating wire 7 is provided between the inner shell 4 and the outer shell 5, the outer shell 5 is covered with an insulation layer 8, the shell is provided with a spray gun hole 9 and a conductive hole 10, and a needle bar 20 is arranged in the conductive hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com