Cut-in oxygen purification device

A technology of oxygen and lifting devices, which is applied in the field of cut-in oxygen purification devices, can solve the problems of low oxygen purity and achieve the effects of improved purification effect, long residence time and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

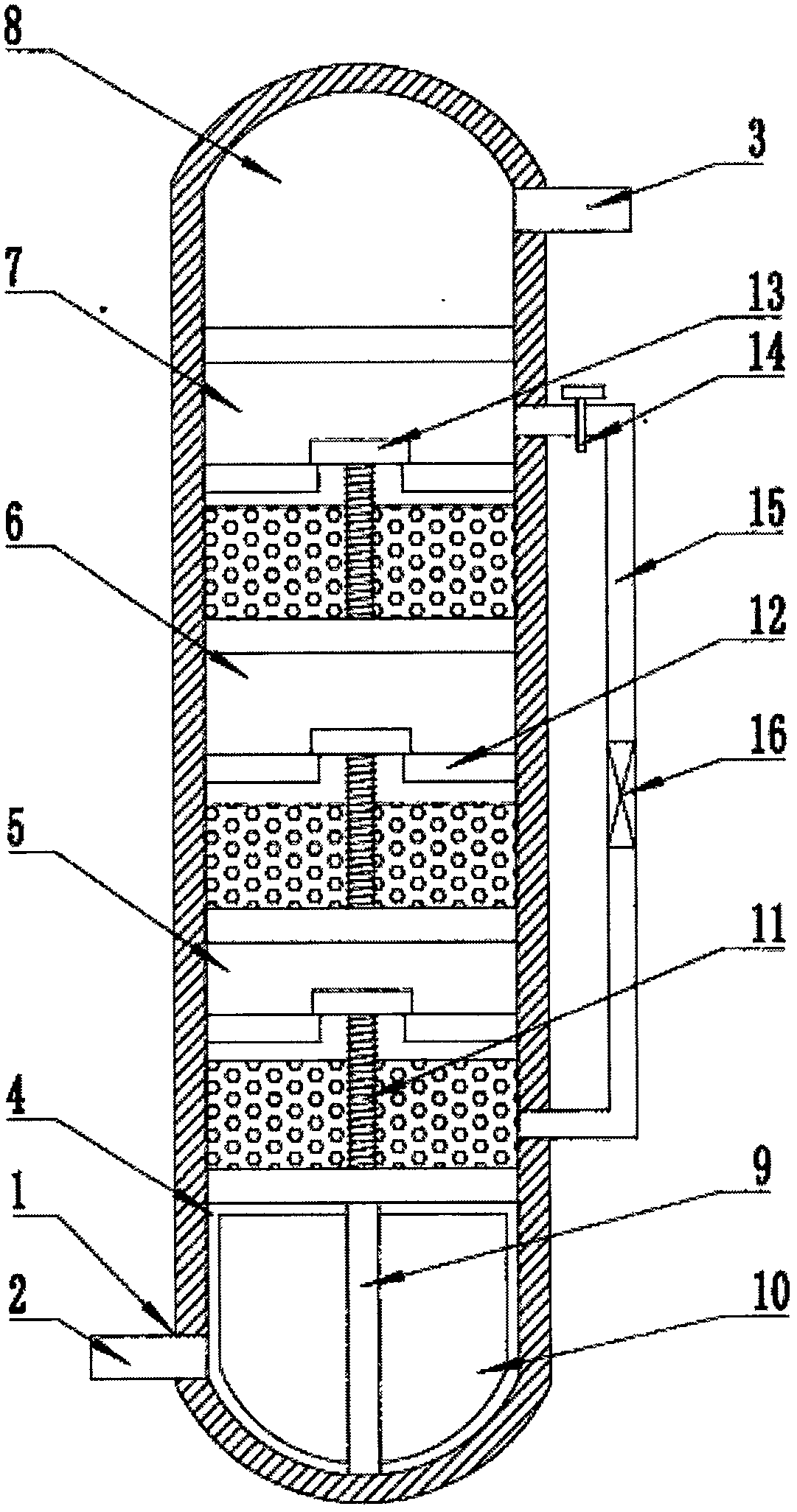

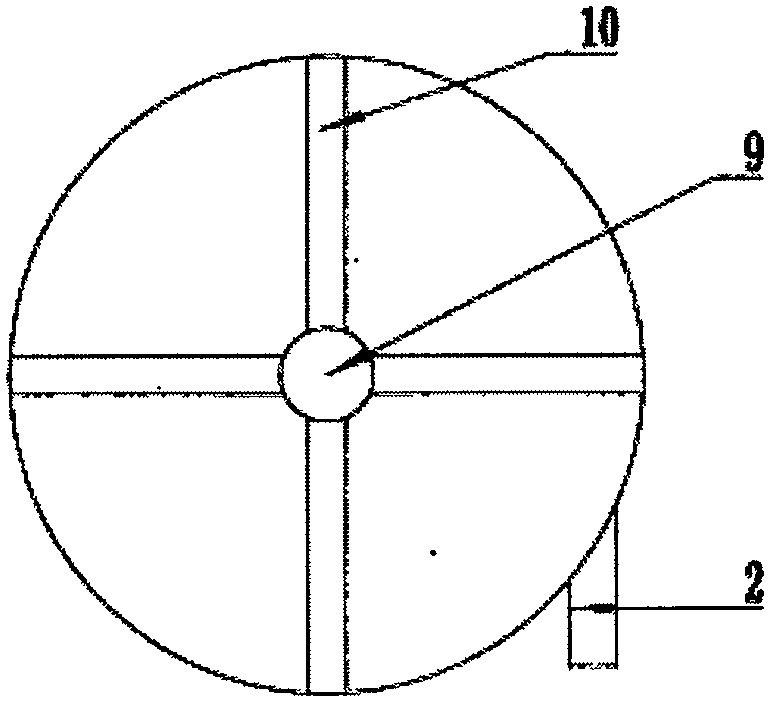

[0019] see Figure 1-2 , a cut-in type oxygen purification device, including a device body 1; the device body 1 is mainly composed of an air inlet 2, an air outlet 3, a swirling flow area 4, a drying area 5, a carbon dioxide removal area 6, and a nitrogen catalytic adsorption area 7 and a buffer zone 8; the device body 1 is sequentially provided with a swirl zone 4, a drying zone 5, a carbon dioxide removal zone 6, a nitrogen catalytic adsorption zone 7 and a buffer zone 8 from bottom to top, and the inside of the drying zone 5 is filled with calcium oxide Particles, the carbon dioxide removal zone 6 is filled with sodium peroxide particles, and the nitrogen catalytic adsorption zone 7 is filled with PU-8 catalytic adsorbent; the bottom of the left side wall of the device body 1 is provided with an air inlet 2, and the air inlet and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com