Automatic test method and system of Venturi air valve

An automated test and Venturi technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of high technical personnel requirements, low testing efficiency, high false detection rate, etc., and achieve excellent performance , reduce the knowledge threshold and the number of testers, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

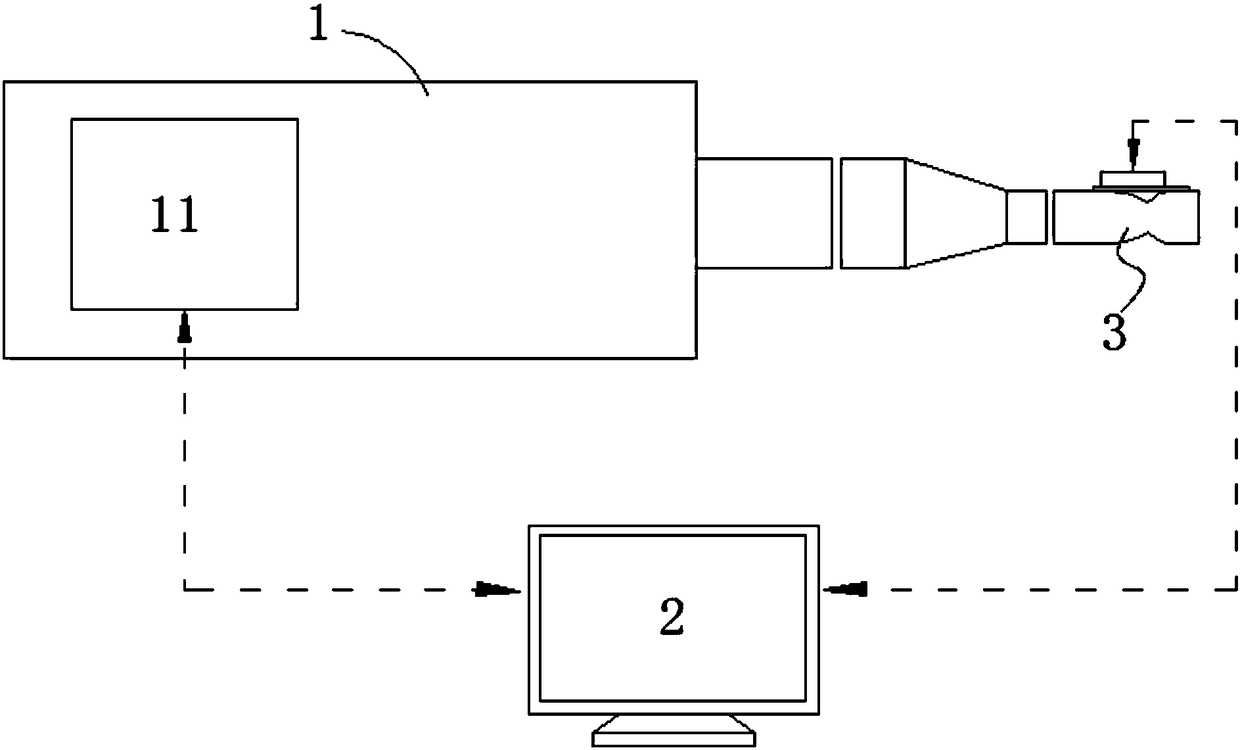

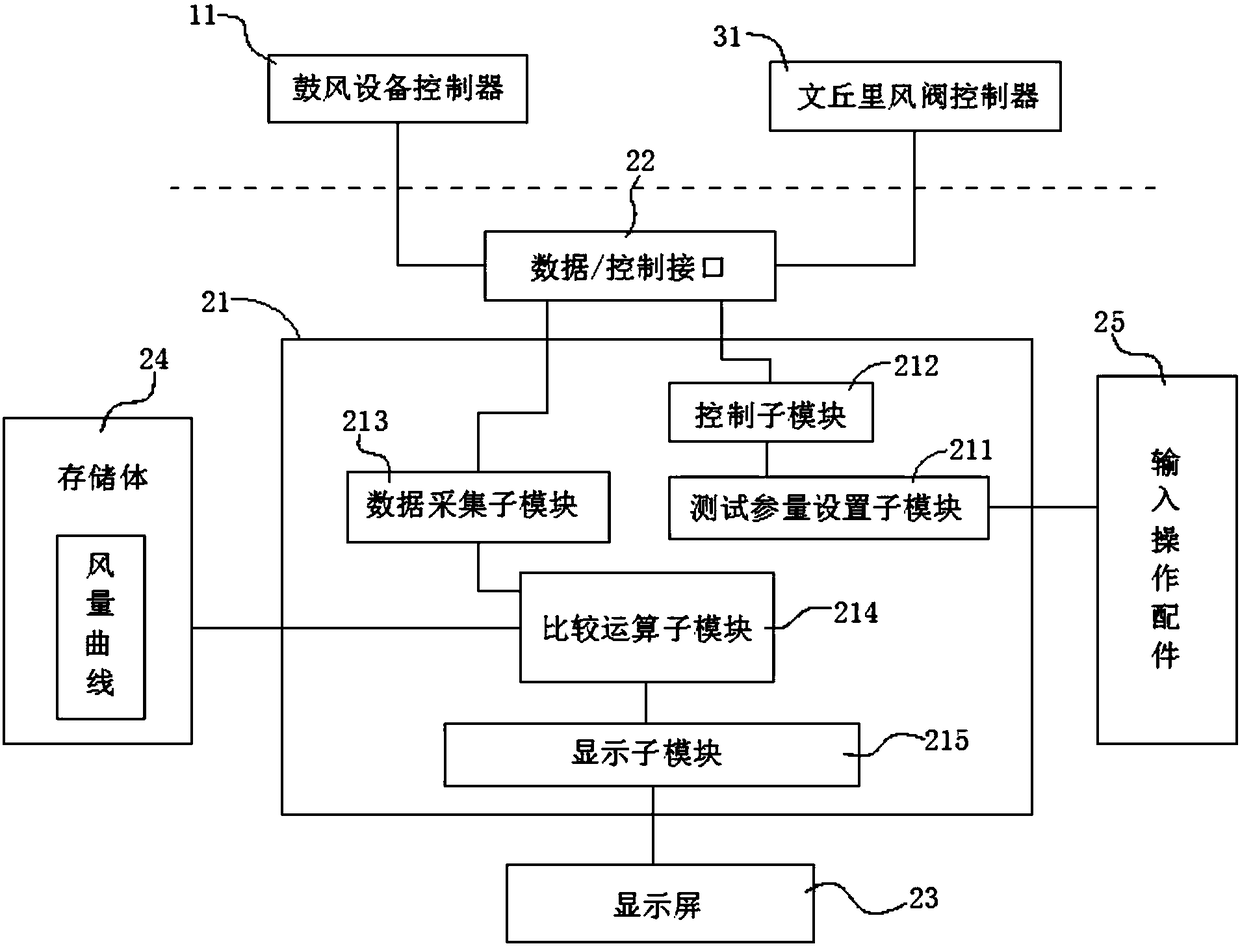

[0022] Attached as follows figure 1 and 2 , to further describe the application scheme:

[0023] An automatic testing method for a Venturi damper, characterized in that it comprises:

[0024] Data recording steps, specifically:

[0025] Set several stroke recording points in the full stroke of the Venturi damper to be tested, run the Venturi damper and obtain real-time air volume data when it reaches the stroke recording point, and form a relationship between the current stroke recording point and the real-time air volume data;

[0026] Verification steps, specifically:

[0027] Run the Venturi damper according to the set ventilation volume values, and obtain the real-time travel position under the current air volume value, and compare the real-time travel position with the travel record point corresponding to the current air volume value in the above association, and calculate the error Value and remind or alarm according to the error value.

[0028] In the data recordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com