Method for recycling and treating hexanoic acid in anaerobic fermentation effluent

A technology for anaerobic fermentation and fermentation broth, which is applied in the field of waste resource treatment and caproic acid recovery and treatment, and can solve problems affecting caproic acid production rate and efficiency, toxicity, and low caproic acid solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: produce caproic acid by anaerobic fermentation

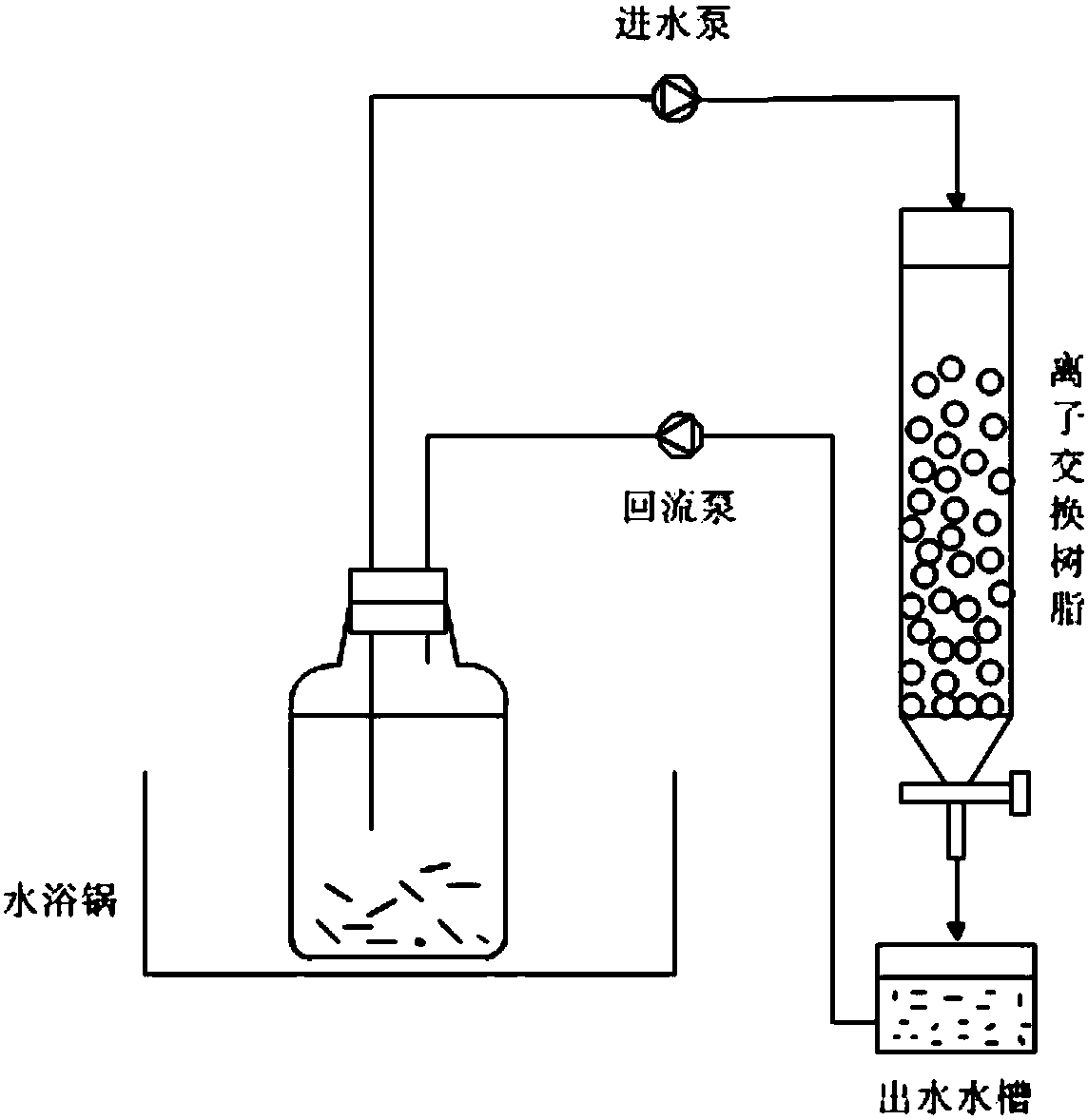

[0033] Application such as figure 1 In the experimental device shown, the anaerobic bottle was placed in a 30°C constant temperature water bath, and the reaction was carried out in a 1L anaerobic bottle. =4.56, alcohols and carboxylic acid concentrations are shown in Table 1), inoculated with 100 g of anaerobic granular sludge (the inoculated sludge was taken from a sewage anaerobic digestion tank of a food processing factory in Wuxi, and the TS was 8%). According to the electron equivalent ratio of ethanol: acetic acid + butyric acid 4:1, add anhydrous ethanol 16g L -1 as an electron donor. When the output of caproic acid is stable and does not change during the reaction, the resin column is connected at regular intervals, the fermentation liquid is pumped into the resin column through the water inlet pump, and the absorbed liquid flows into the anaerobic bottle again through the reflux pump. When the et...

Embodiment 2

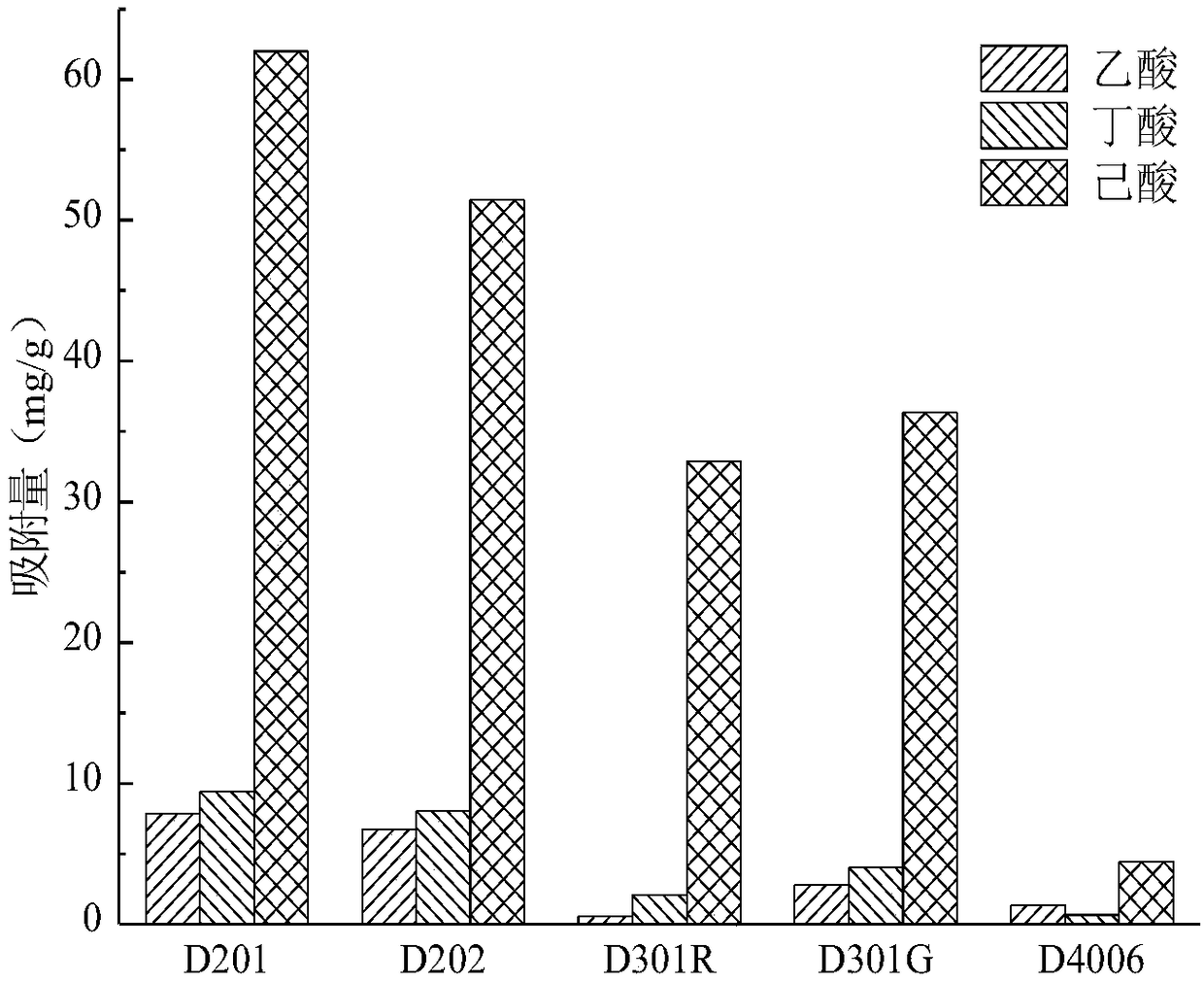

[0039] Example 2: Adsorption effects corresponding to different resins

[0040] Put the pretreated 15g resin in a 250mL Erlenmeyer flask, add 150mL simulated fermentation broth (pH7.0) at the same time, put the Erlenmeyer flask in a 30°C incubator and let it stand for 5h. After adsorption balance, take the supernatant to measure the acetic acid in it. , Butyric acid, caproic acid concentration. Five different types of resins were used to adsorb the simulated fermentation broth, and the adsorption equilibrium was as follows: figure 2 , under the same adsorption conditions, the adsorption capacity of D201 resin to acetic acid, butyric acid and hexanoic acid were 7.85, 9.42 and 62.0 mg·g respectively -1, the adsorption rates were 27.11, 31.73 and 55.41% respectively; the adsorption capacity of D202 resin to the three acids was 6.74, 8.04 and 51.44 mg·g -1 , and the adsorption rates were 24.03, 27.81, and 46.57%, respectively. These two resins meet the requirements of the resi...

Embodiment 3

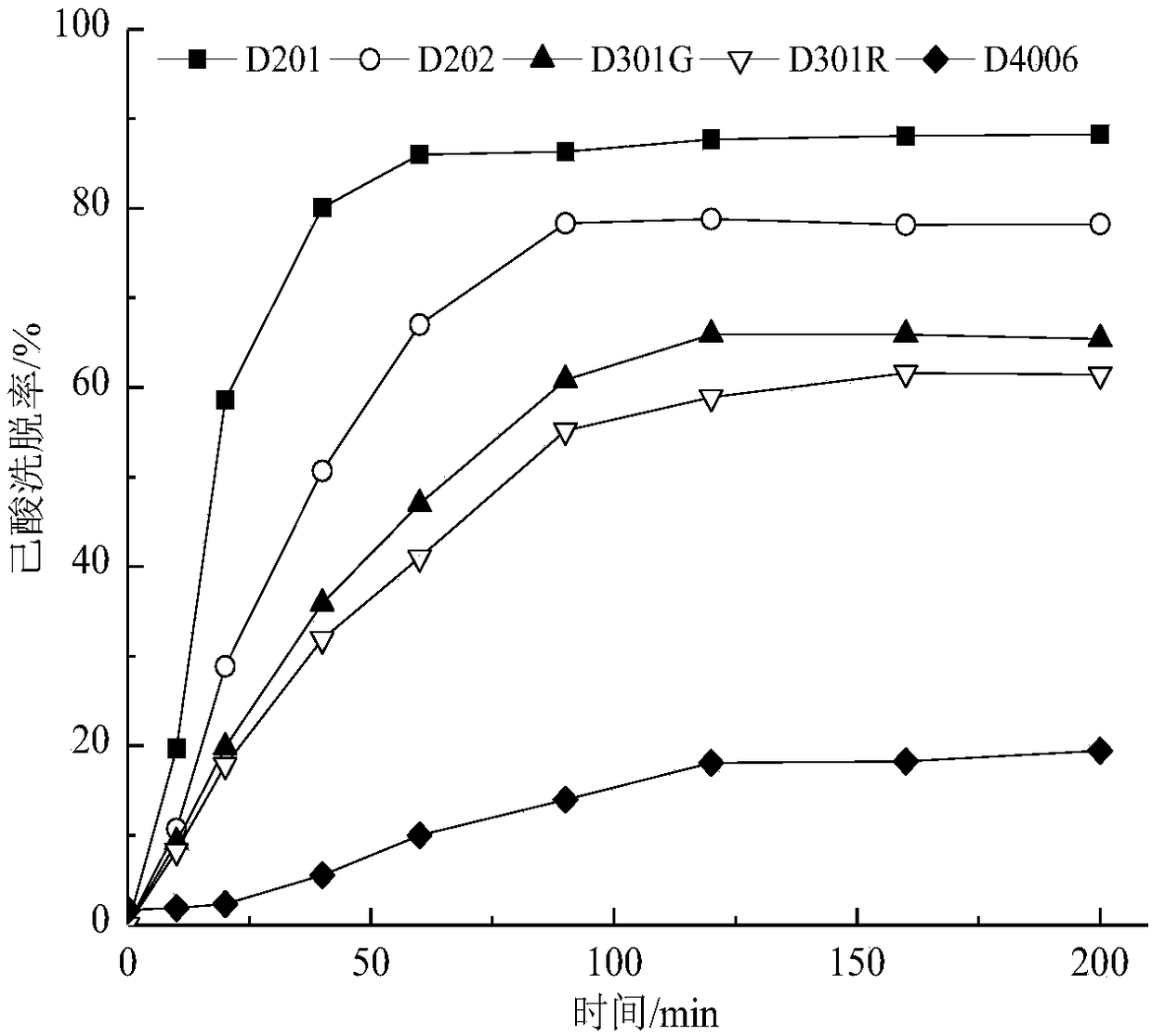

[0044] Example 3: The elution effect of resin D201 on hexanoic acid under different conditions

[0045] According to the adsorption method in Example 2, the D201 resin was adsorbed. After the adsorption equilibrium, the resin was divided into 7 parts (15g of resin per part) and put into conical flasks, and 150mL of eluent was added to each part to study the elution conditions. Figure 4 , 5 Respectively, the effects of different eluent temperature and eluent concentration on the elution efficiency of acetic acid, butyric acid and hexanoic acid in D201 resin. It can be seen from the figure that when the elution temperature is 10°C, the elution efficiency of the three acids is low; when the elution temperature is 30°C, the elution efficiency increases, and the elution efficiencies of acetic acid, butyric acid, and hexanoic acid are 95%, 86.7%, respectively. %, 90.7%; the elution efficiency was 94.9%, 85%, 90% at a temperature of 40°C, which was close to the elution rate at 30°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com