A kind of solid composite for lubricating flame retardant system and its preparation and application method

A compound and system technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve problems such as poor impact resistance, odor, shrinkage, etc., achieve good extreme pressure resistance, simple process, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] See Table 1 for the formula and dosage of the solid compound for lubrication of the flame retardant system in this example.

[0044] The consumption of each raw material component in the present embodiment of table 1

[0045] components Mass percent (wt%) Polypropylene Wax 70.1 Molybdenum disulfide 2.6 Organic Kaolin 1.5 magnesium hydroxide 10.3 graphite 5.0 polyphosphate 7.5 Zinc stearate 2.0 Titanate coupling agent 1.0

[0046] The solid compound for the lubrication of the flame retardant system of the above formula is prepared according to the following method:

[0047] (1) Material mixing

[0048] Each solid powder that has been weighed comprises lubricant (polypropylene wax), lubricating aid (molybdenum disulfide), flame retardant (organic kaolin, magnesium hydroxide, graphite and polyphosphate), modifier ( Zinc stearate) and coupling agent (titanate coupling agent) are mixed and poured into a high-sp...

Embodiment 2

[0060] See Table 2 for the formula and dosage of the solid compound for lubrication of the flame retardant system in this embodiment.

[0061] The consumption of each raw material component of table 2 present embodiment

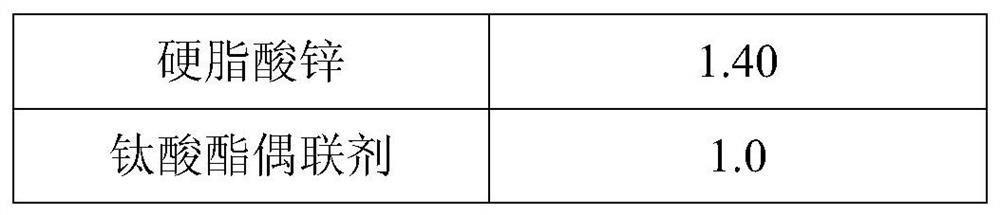

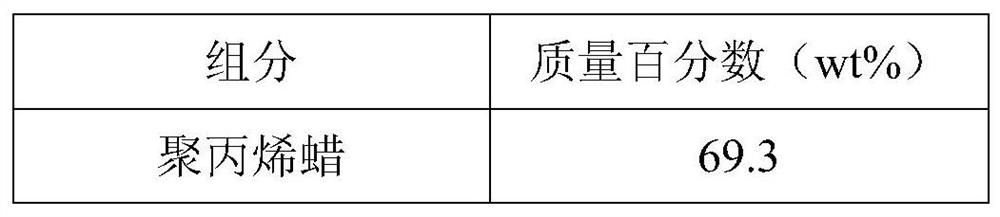

[0062]

[0063]

[0064] The solid compound for the lubrication of the flame retardant system of the above formula is prepared according to the following method:

[0065] (1) Material mixing

[0066] Each solid powder that has been weighed comprises lubricant (polyethylene wax), lubricating aid (molybdenum disulfide), flame retardant (organic kaolin, magnesium hydroxide, graphite and polyphosphate), modifier ( Zinc stearate) and coupling agent (titanate coupling agent) are mixed and poured into a high-speed pulverizer to pulverize and mix;

[0067] (2) Melt dispersion

[0068] Pour the mixed materials into a beaker, then place the beaker in an electric heating mantle, control the digital display temperature at 140°C, and heat to melt. Turn on the di...

Embodiment 3

[0078] See Table 3 for the formula and dosage of the solid compound for lubrication of the flame retardant system in this example.

[0079] The consumption of each raw material component in the present embodiment of table 3

[0080]

[0081]

[0082] The solid compound for the lubrication of the flame retardant system of the above formula is prepared according to the following method:

[0083] (1) Material mixing

[0084] Each solid powder that has been weighed comprises lubricant (polypropylene wax), lubricating aid (molybdenum disulfide), flame retardant (organic kaolin, magnesium hydroxide, graphite and polyphosphate), modifier ( zinc stearate) and coupling agent (silane coupling agent) are mixed and poured into a high-speed pulverizer to pulverize and mix;

[0085] (2) Melt dispersion

[0086] Pour the mixed materials into a beaker, then place the beaker in an electric heating mantle, control the temperature at 180°C, and heat to melt. Turn on the disperser, rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com