Heat transfer printing powder coating used for aluminum floor, and preparation method and application of heat transfer printing powder coating

A technology of powder coating and thermal transfer printing, which is applied in powder coating, anti-corrosion coating, polyester coating, etc. It can solve the problems of affecting the appearance and service life, the aluminum floor is easy to be scratched, and the surface hardness is low, so as to ensure stable storage properties, ensuring easy and sufficient curing, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In addition, the present invention also provides a preparation method of thermal transfer powder coating for aluminum floor, comprising the following steps:

[0046] (1) The carboxyl-terminated polyester resin and the hydroxyl-terminated polyester resin are pre-mixed in a ratio of 1:1-4:1, and then melt-extruded with a single-screw extruder, and the extrusion temperature is controlled at 90-110°C, the screw frequency is controlled at 30-50Hz, and then the extruded flakes are crushed to obtain a polyester mixture;

[0047] (2) Put the polyester mixture and other materials in the raw material into the mixing tank with crushing function according to the mass percentage of the above formula for pre-mixing, the time is 3-5 minutes;

[0048] (3) Use a twin-screw extruder to melt, knead, disperse and extrude the pre-mixed raw materials, wherein the extrusion temperature is controlled at 110-130 ° C, and the screw frequency is controlled at 30-50 Hz; pieces, broken;

[0049] (4...

Embodiment 1

[0053] Prepare the thermal transfer powder coating for aluminum floor according to the following steps:

[0054] In the first step, the carboxyl-terminated polyester resin and hydroxyl-terminated polyester resin according to the present invention are pre-mixed in a ratio of 2:1, and then melt-extruded with a single-screw extruder, and the extrusion temperature is set at 105°C , the screw frequency is set to 50Hz, and then the extruded sheet is crushed to obtain a polyester mixture;

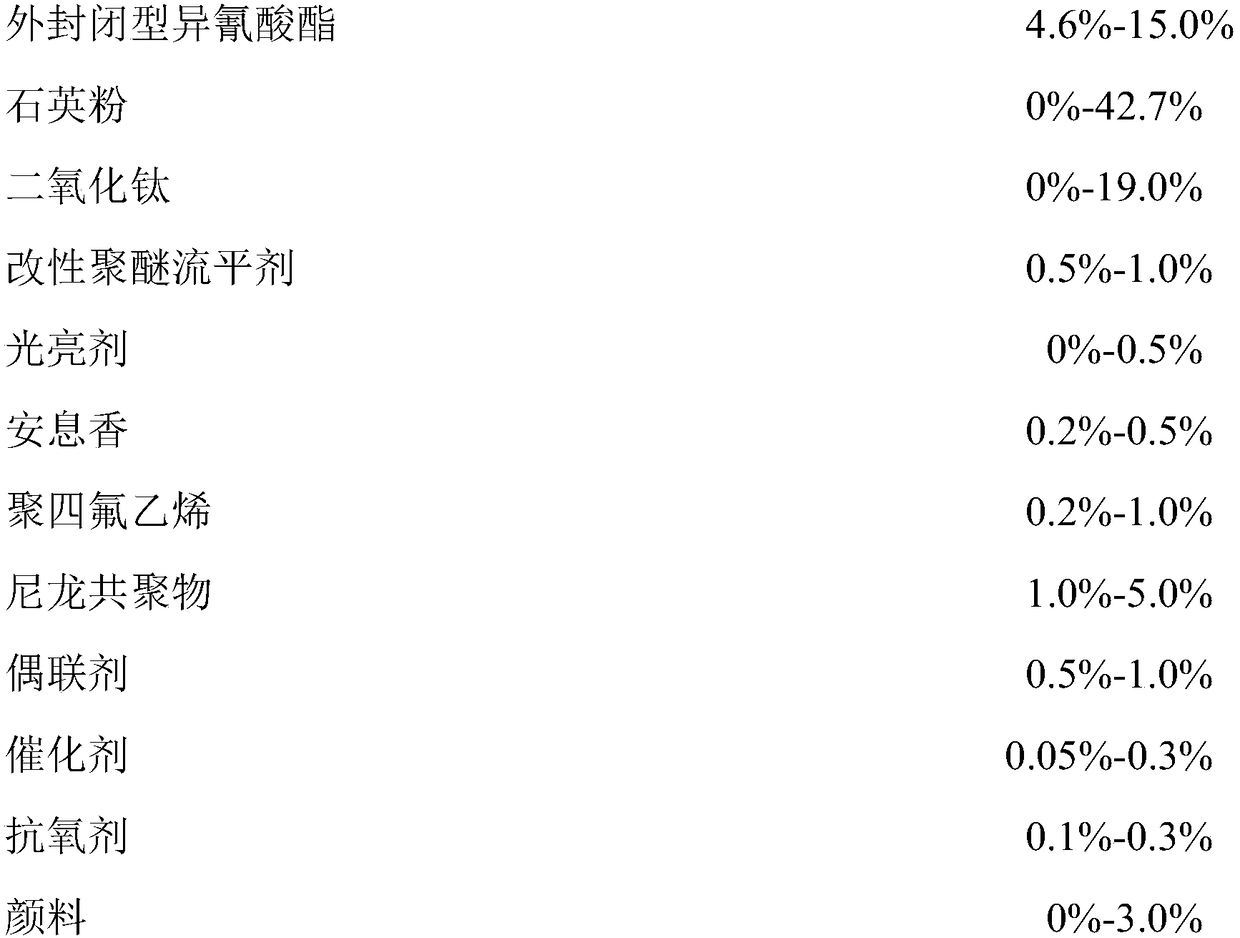

[0055] In the second step, the polyester mixture and other raw materials are put into the mixing tank with crushing function according to the mass percentage of the following formula for pre-mixing, and the time is 3-5 minutes;

[0056]

[0057] The third step is to use a twin-screw extruder to melt, knead and evenly disperse the pre-mixed raw materials and extrude them. The extrusion temperature is controlled at 120°C and the screw frequency is controlled at 35Hz; then tableting and crushing a...

Embodiment 2

[0063] Prepare the thermal transfer powder coating for aluminum floor according to the following steps:

[0064] In the first step, the carboxyl-terminated polyester resin and hydroxyl-terminated polyester resin according to the present invention are pre-mixed in a ratio of 1:1, and then melt-extruded with a single-screw extruder, and the extrusion temperature is set at 100°C , the screw frequency is set to 40Hz, and then the extruded sheet is crushed to obtain a polyester mixture;

[0065] In the second step, the polyester mixture and other raw materials are put into the mixing tank with crushing function according to the mass percentage of the following formula for pre-mixing, and the time is 3-5 minutes;

[0066]

[0067]

[0068] The third step is to use a twin-screw extruder to melt, knead and evenly disperse and extrude the pre-mixed raw materials. The extrusion temperature is controlled at 130°C and the screw frequency is controlled at 40Hz; then tableting and cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com