Concrete low-water-absorption protecting agent, preparation method and application method thereof

A low water absorption, protective agent technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of coating deformation and falling off, lack of air permeability, and inability to protect concrete for a long time, achieve simple production equipment and improve durability. The effect of sex and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An ultra-low water absorption concrete protective agent prepared by the following method:

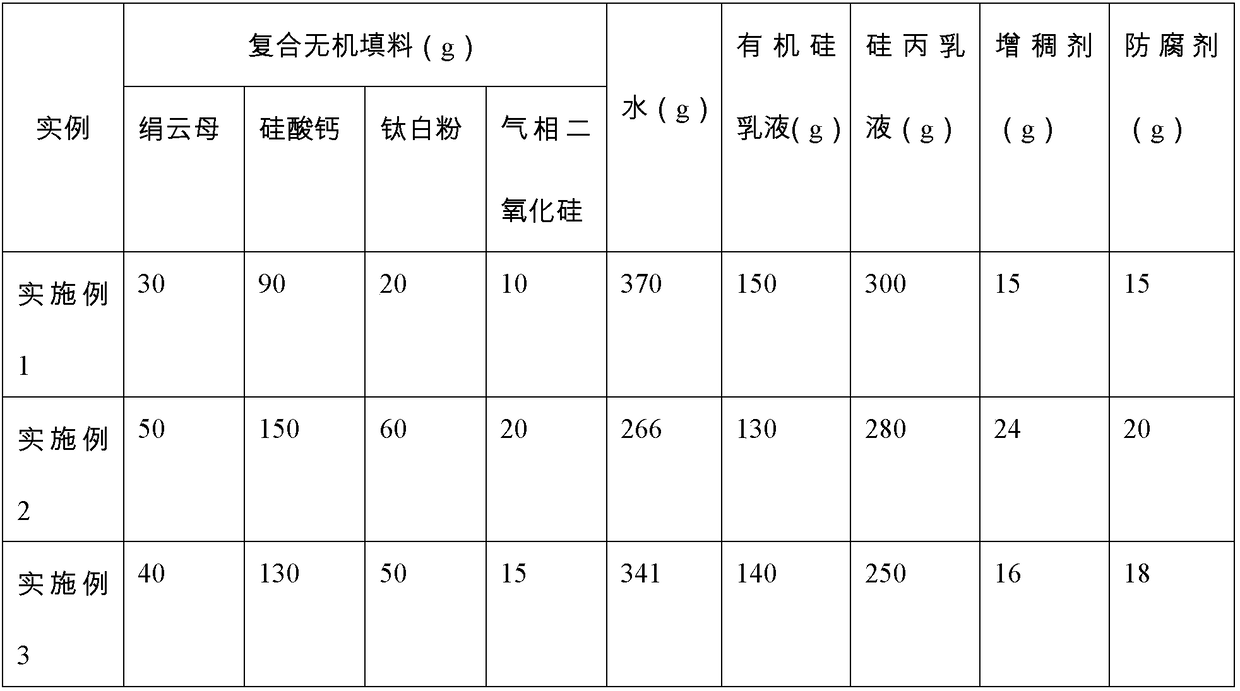

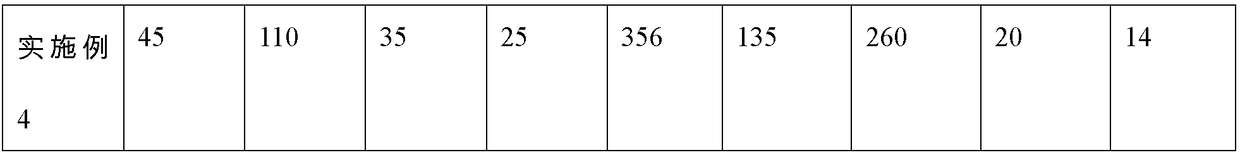

[0024] (1) Make ingredients according to Table 1.

[0025] (2) Mix 150g of the composite inorganic filler and add it to water to disperse at a high speed of 1000 rpm for 80 minutes, then reduce the dispersion speed to 600 rpm, and then add silicone emulsion BS43N150g and silicone acrylic emulsion A-79 ( B) 300g, 15g of thickener hydroxyethyl cellulose, 15g of MV preservative, and stirring for 40 minutes, you can get an ultra-low water absorption concrete protective agent.

[0026] Performance Testing:

[0027] Coated on the surface of concrete, the water absorption rate (48h) is 93% lower than the reference specimen; the artificial weather resistance (5000h) is apparently intact; the water resistance (192h) is apparently intact.

Embodiment 2

[0029] An ultra-low water absorption concrete protective agent prepared by the following method:

[0030] (1) Make ingredients according to Table 1.

[0031] (2) Mix 280g of the composite inorganic filler and add it to water to disperse at a high speed of 1200 rpm for 70 minutes, then reduce the dispersion speed to 500 rpm, and then add silicone emulsion BS45130g and silicone acrylic emulsion A-79 ( B) 280g, 24g of hydroxyethyl cellulose thickener, 20g of MV preservative, etc., stir for 50 minutes, and then you can get a super low water absorption concrete protective agent.

[0032] Performance Testing:

[0033] Coated on the surface of concrete, the water absorption rate (48h) is 85% lower than the reference specimen; the artificial weather resistance (5500h) is apparently intact; the water resistance (192h) is apparently intact.

Embodiment 3

[0035] An ultra-low water absorption concrete protective agent prepared by the following method:

[0036] (1) Make ingredients according to Table 1.

[0037] (2) Mix 235g of the composite inorganic filler and add it to water and disperse at a high speed of 1100 rpm for 75 minutes, then reduce the dispersion speed to 550 rpm, and then add silicone emulsion BS43N140g and silicone acrylic emulsion A-79 ( B) 250g, 16g of hydroxyethyl cellulose thickener, 18g of MV preservative, and stirring for 55 minutes, you can get a super-low water absorption concrete protective agent.

[0038] Performance Testing:

[0039] Coated on the surface of concrete, the water absorption rate (48h) is 94% lower than the reference specimen; the artificial weather resistance (5000h) is apparently intact; the water resistance (192h) is apparently intact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com