Super-hydrophobic and super-selfcleaning composite coating and preparation method thereof as well as selfcleaning insulator used by super-hydrophobic and super-selfcleaning composite coating

A composite coating, super self-cleaning technology, applied in anti-fouling/underwater coatings, insulators, coatings, etc., can solve the problems of high RTV stress, easy to burst, and limited life of anti-fouling products, and achieve high-strength adhesion, Excellent water spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A self-cleaning insulator, including an insulator body, the outer surface of the above-mentioned insulator body is provided with a paint coating formed by a super-hydrophobic super-self-cleaning composite coating, the thickness of the coating is 50 μm, and the super-hydrophobic super-self-cleaning composite coating is The preparation method comprises the following steps:

[0024] 1) Add 2 parts of polytetrafluoroethylene powder to 10 parts of nano-hydrophobic agent under stirring state, stir for 5 minutes to make it evenly mixed;

[0025] 2) Add 0.3 parts of polyazide silane paint to the mixed solution obtained in step 1) under stirring, stir for 5 minutes to make it evenly mixed, and then the super-hydrophobic and super-self-cleaning composite paint can be obtained;

[0026] Wherein, the nano-hydrophobic agent is selected from NM-V15, and the polytetrafluoroethylene powder has a particle size of 3 μm.

Embodiment 2

[0028] A self-cleaning insulator, comprising an insulator body, the outer surface of the above-mentioned insulator body is provided with a paint coating formed by a super-hydrophobic super-self-cleaning composite coating, the thickness of the coating is 60 μm, and the super-hydrophobic super-self-cleaning composite coating is The preparation method comprises the following steps:

[0029] 1) Add 3.5 parts of polytetrafluoroethylene powder to 12 parts of nano-hydrophobic agent under stirring, and stir for 5 minutes to make it evenly mixed;

[0030] 2) Add 0.5 parts of polyazide silane paint to the mixed solution obtained in step 1) under stirring, stir for 7 minutes to make it evenly mixed, and then the super-hydrophobic and super-self-cleaning composite paint can be obtained;

[0031] Wherein, the nano-hydrophobic agent is selected from NM-V15, and the particle size of polytetrafluoroethylene powder is 7 μm.

Embodiment 3

[0033] A self-cleaning insulator, including an insulator body, the outer surface of the above-mentioned insulator body is provided with a paint coating formed by a super-hydrophobic super-self-cleaning composite coating, the thickness of the coating is 70 μm, and the super-hydrophobic super-self-cleaning composite coating is The preparation method comprises the following steps:

[0034] 1) Add 6 parts of polytetrafluoroethylene powder to 15 parts of nano-hydrophobic agent under stirring state, stir for 7 minutes to make it evenly mixed;

[0035] 2) Add 0.8 parts of polyazoxysilane paint to the mixed solution obtained in step 1) under stirring, stir for 5 minutes to make it evenly mixed, and then obtain the super-hydrophobic and super-self-cleaning composite paint;

[0036] Wherein, the nano-hydrophobic agent is selected from NM-V15, and the polytetrafluoroethylene powder has a particle size of 15 μm.

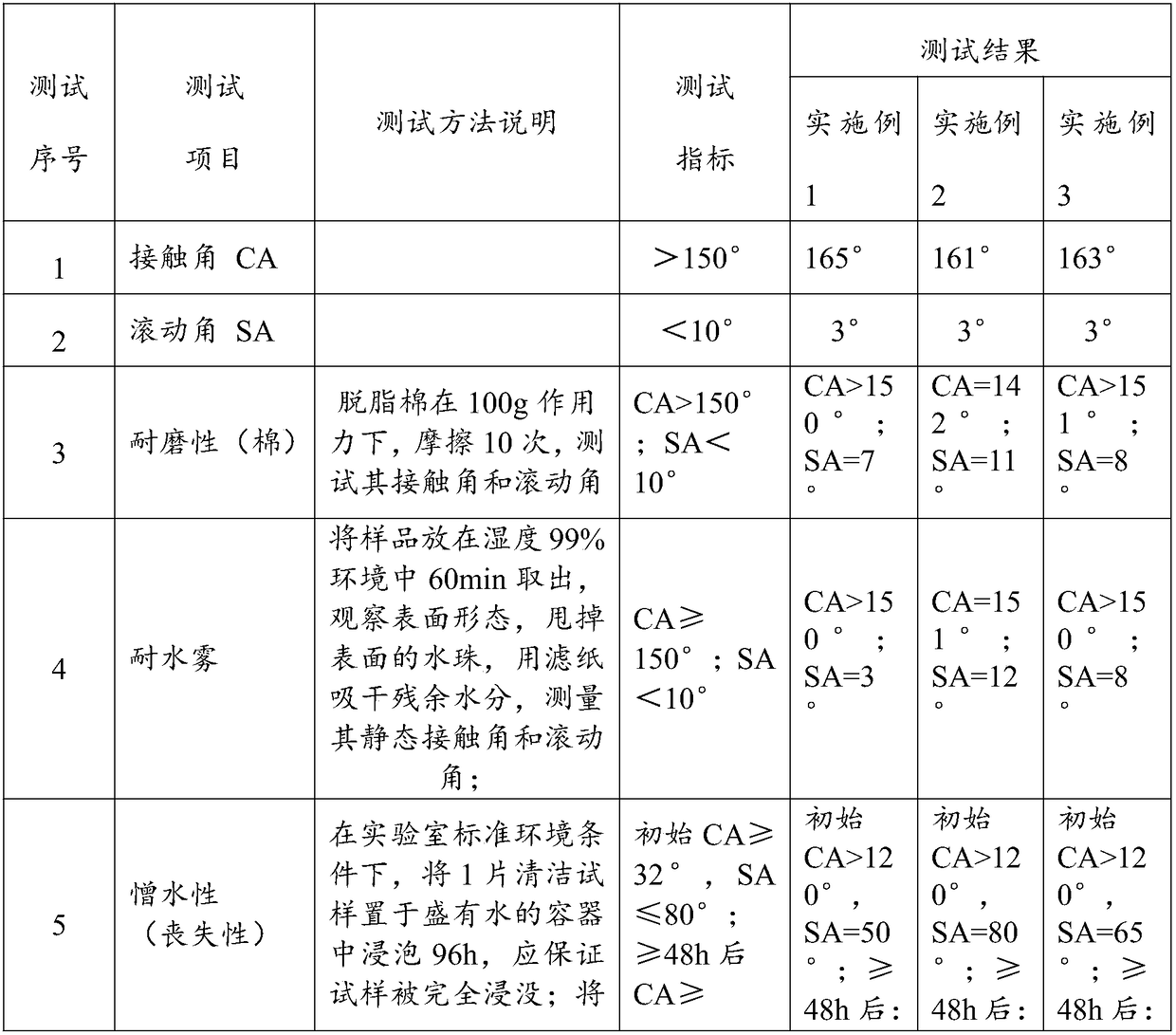

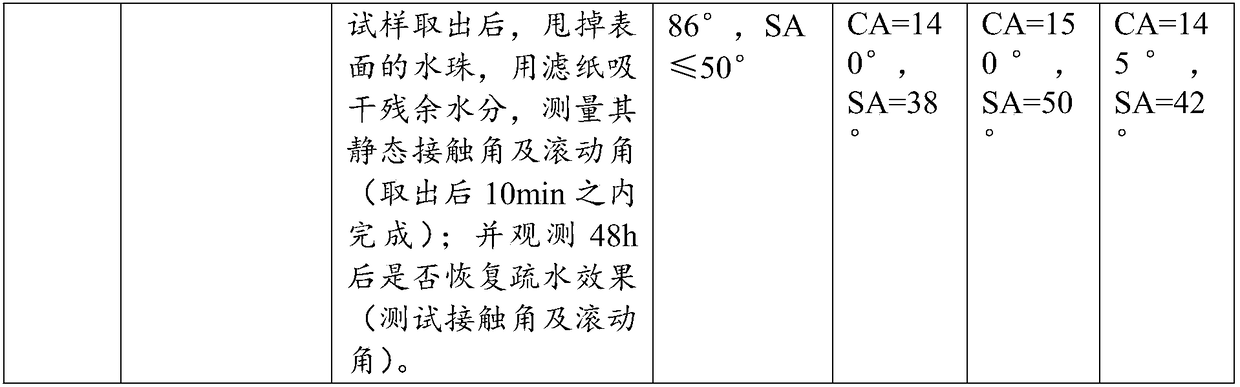

[0037] The performance tests of the self-cleaning insulators provided in E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com