PVDC coating material with high barrier performance and preparation method thereof

A coating material and high barrier technology, applied in coatings, antifouling/underwater coatings, paints containing biocide, etc., can solve the problems of poor thermal stability and barrier failure of PVDC latex, and achieve strong light redox Function, anti-sedimentation and coagulation, strong bactericidal and anti-mildew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

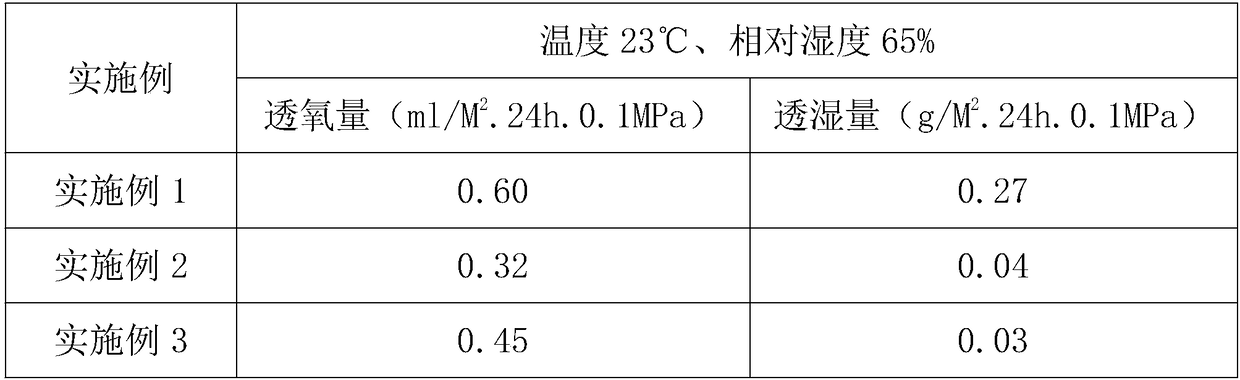

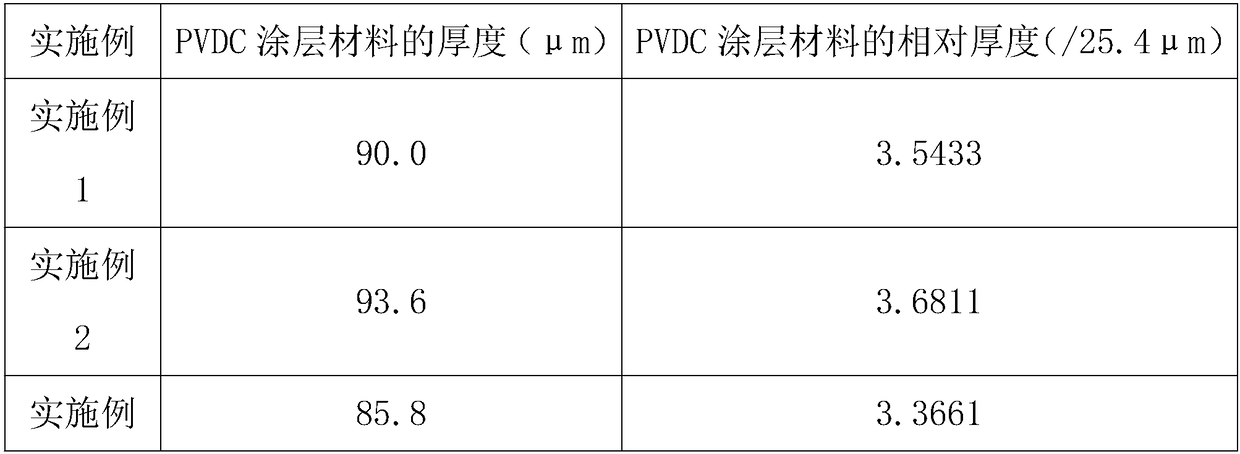

Examples

Embodiment 1

[0050] (1) Evenly disperse 10 parts by mass of silica nanoparticles with a particle size of 30nm in 50 parts by mass of ultrapure water, heat to 80°C, stir for 5min, and then add 0.05 parts by mass of ammonia water and 0.4 parts by mass of Aminopropyltriethoxysilane, fully stirred for 6 hours, cooled to room temperature, centrifuged, rinsed with deionized water three times, washed the unreacted substances to obtain a solid, and put the obtained solid into a ball mill for 12 hours , to obtain amino-modified silica powder;

[0051] (2) Add 0.5 g of amino-modified silica powder to 20 parts by mass of ultrapure water, stir and dissolve fully, add 2 parts by mass of piperazine aqueous solution with a mass fraction of 2%, and add 3 parts by mass after stirring and dissolving The mass fraction of one part is 3% triethylamine, after stirring and dissolving, the aqueous phase solution is prepared;

[0052] (3) Dissolve 10 parts by mass of trimesoyl chloride light yellow solid powder i...

Embodiment 2

[0068] (1) Evenly disperse 12 parts by mass of silica nanoparticles with a particle size of 50nm in 55 parts by mass of ultrapure water, heat to 90°C, stir for 8min, and then add 0.08 parts by mass of ammonia water and 0.8 parts by mass of Aminopropyltriethoxysilane, fully stirred for 6 hours, cooled to room temperature, centrifuged, rinsed with deionized water three times, washed the unreacted substances to obtain a solid, and put the obtained solid into a ball mill for 12 hours , to obtain amino-modified silica powder;

[0069] (2) Add 0.8 g of amino-modified silica powder to 25 parts by mass of ultrapure water. After fully stirring and dissolving, add 4 parts by mass of piperazine aqueous solution with a mass fraction of 2%. After stirring and dissolving, add 5 parts by mass of The mass fraction of one part is 3% triethylamine, after stirring and dissolving, the aqueous phase solution is prepared;

[0070] (3) dissolving 15 parts by mass of trimesoyl chloride light yellow ...

Embodiment 3

[0086] (1) Evenly disperse 15 parts by mass of silica nanoparticles with a particle size of 60nm in 60 parts by mass of ultrapure water, heat to 100°C, stir for 10 minutes, and then add 0.08 parts by mass of ammonia water and 1 part by mass of Aminopropyltriethoxysilane, fully stirred for 6 hours, cooled to room temperature, centrifuged, rinsed with deionized water three times, washed the unreacted substances to obtain a solid, and put the obtained solid into a ball mill for 12 hours , to obtain amino-modified silica powder;

[0087] (2) Add 1.0 g of amino-modified silica powder to 30 parts by mass of ultrapure water. After fully stirring and dissolving, add 5 parts by mass of piperazine aqueous solution with a mass fraction of 2%. After stirring and dissolving, add 7 mass parts The mass fraction of one part is 3% triethylamine, after stirring and dissolving, the aqueous phase solution is prepared;

[0088] (3) Dissolve 15 parts by mass of trimesoyl chloride light yellow soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com