Preparation method and application of phosphate-group-containing low-molecular-weight water reducing agent for concrete

A concrete water-reducing agent and low-molecular-weight technology, applied in the field of concrete admixtures, can solve the problem of low density of adsorption groups, achieve excellent retardation, increase density and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

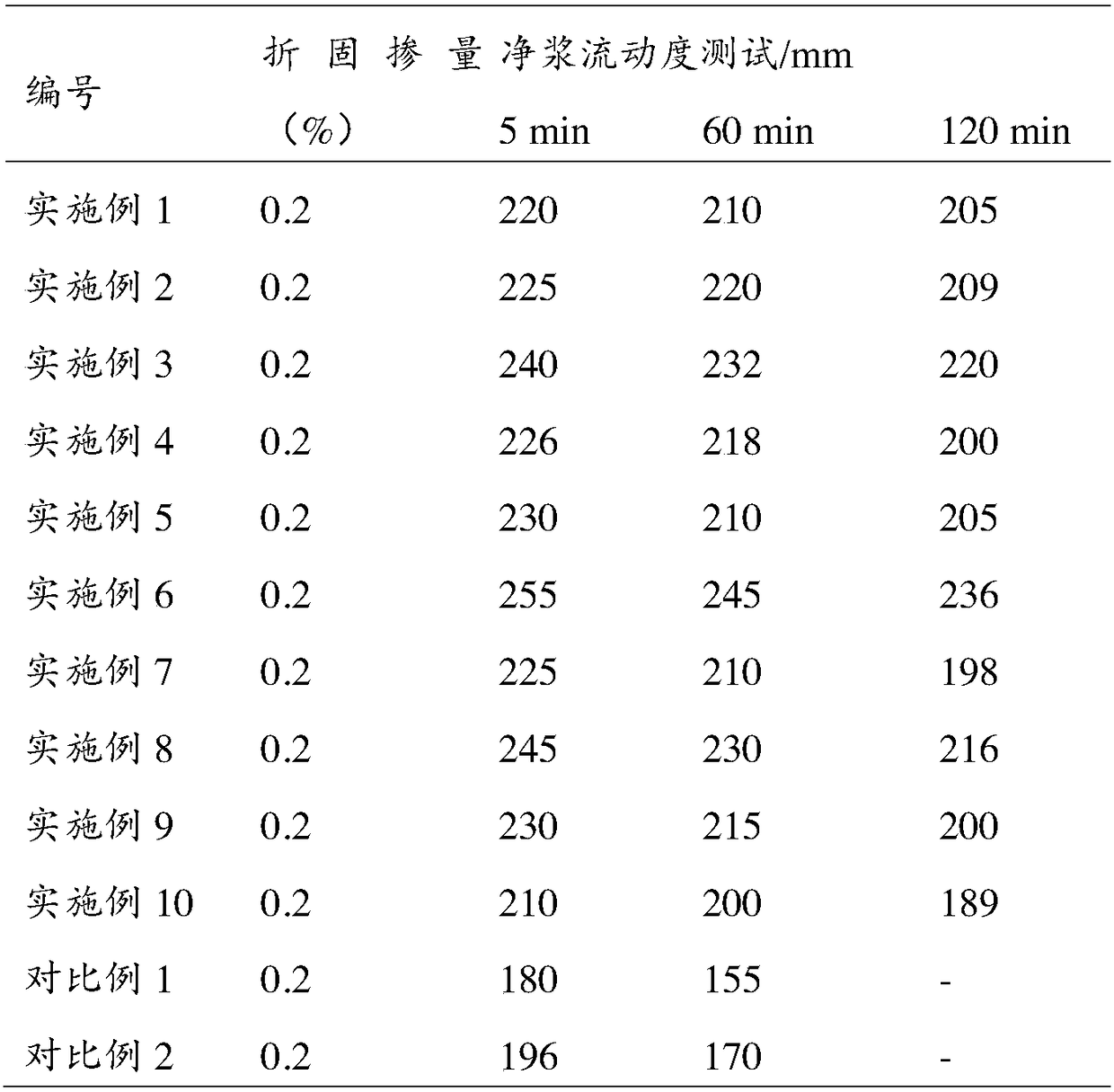

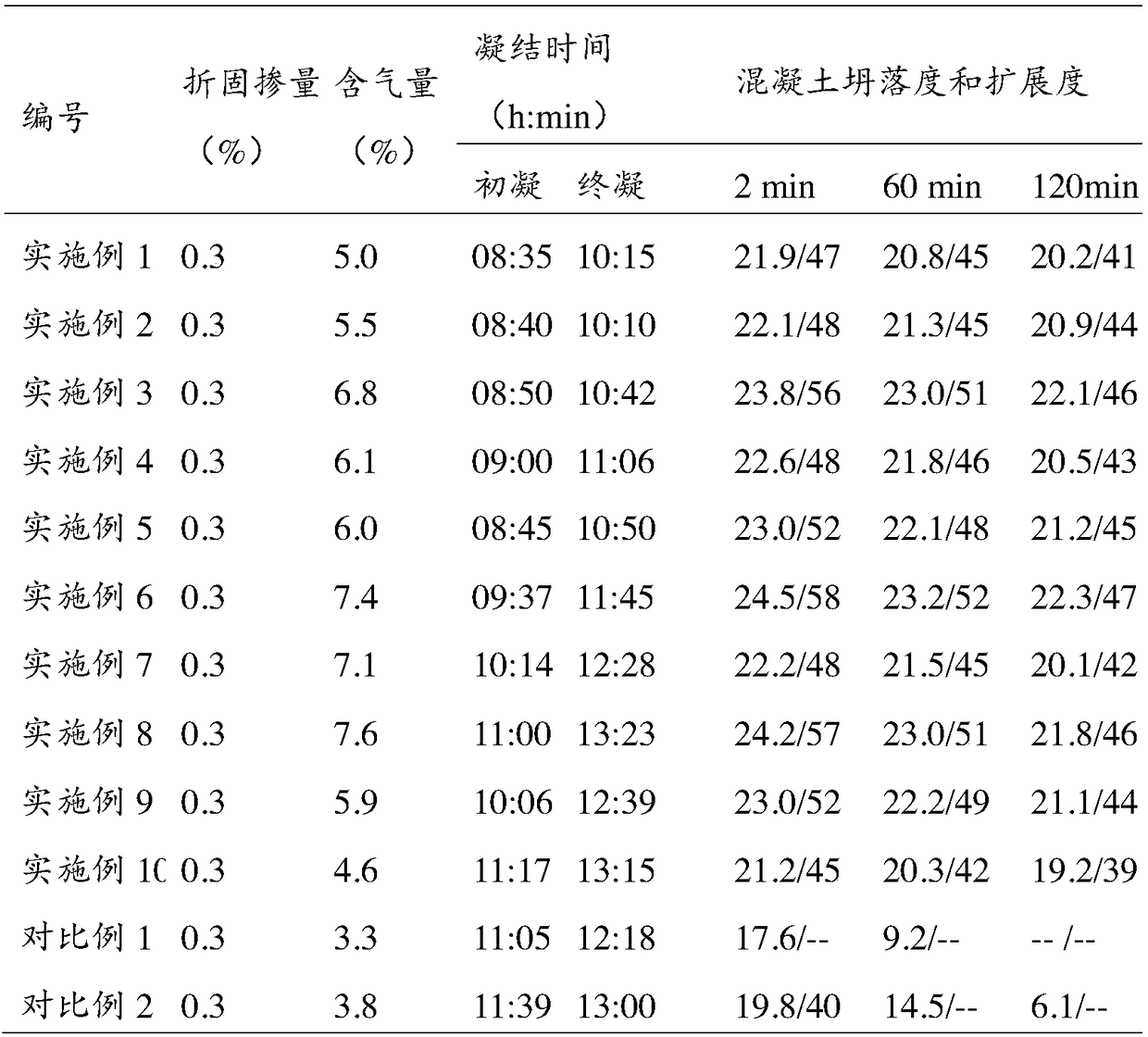

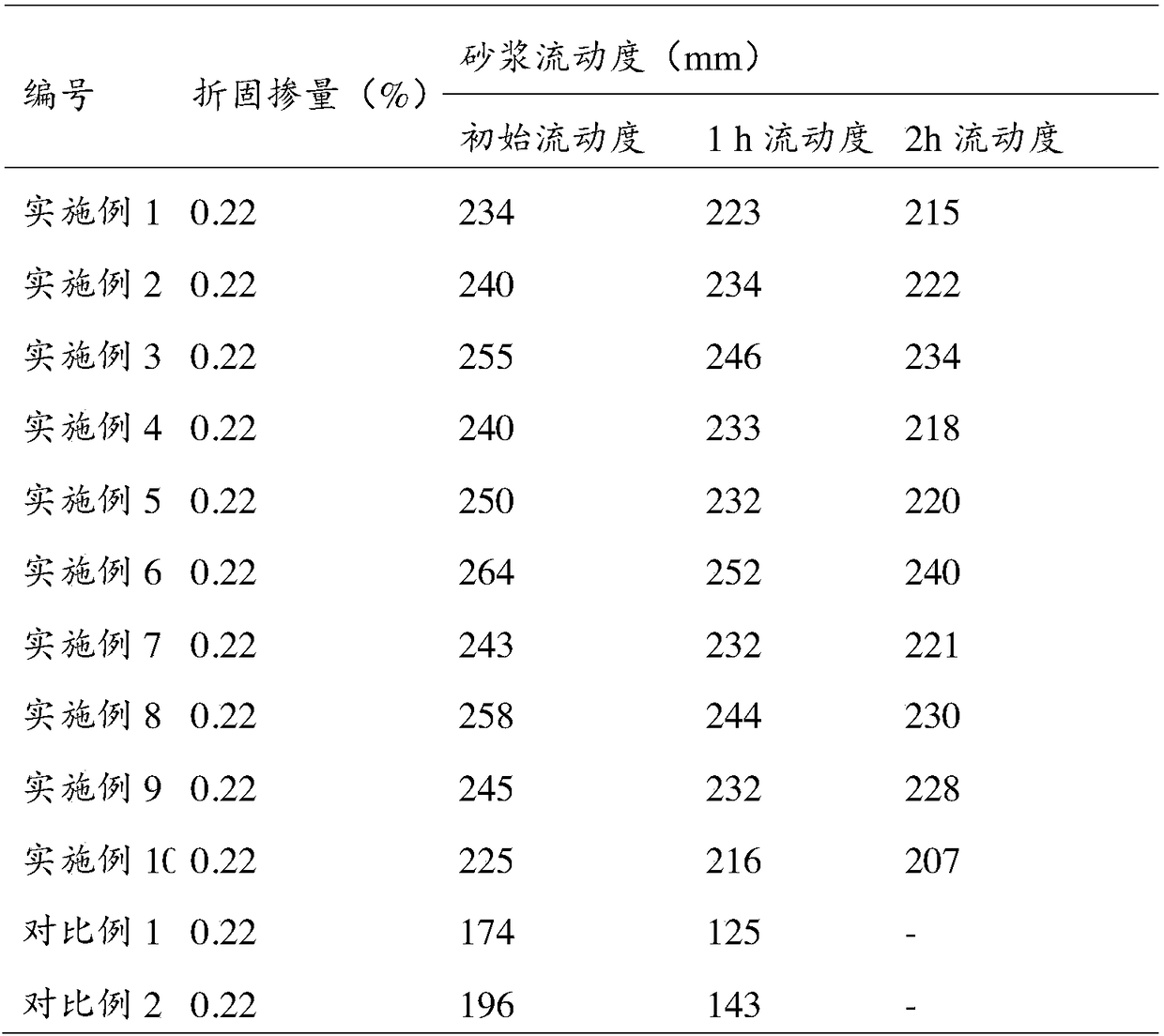

Examples

Embodiment 1

[0055] The synthesis process of polyether polyol with a molecular weight of 400 (pentaerythritol as the initiator) is as follows: Weigh 136.2 parts of pentaerythritol and 50-100 parts of ethylene glycol dimethyl ether, add them into the reactor and stir evenly, then add 2.7 parts of NaH, continue Under the condition of stirring, 263.8 parts of ethylene oxide was introduced, and the temperature was raised to 80-120°C to carry out the reaction, and the reaction was stopped after the pressure of the system no longer decreased. Then distill under reduced pressure at 80-90°C to remove ethylene glycol dimethyl ether to obtain polyether polyol. The molecular weight measured by GPC is 405, and the molecular weight distribution is 1.03.

[0056] The molar ratio of polyether polyol with a molecular weight of 400 (pentaerythritol as the initiator) and sodium is 1:1.1, the molecular weight of MPEG-Cl is 600, and the molar ratio of MPEG-Cl to polyether polyol is 1.1:1 , the molar ratio of...

Embodiment 2

[0058] The synthetic process of the polyether polyol (pentaerythritol as the initiator) with a molecular weight of 400 is the same as above.

[0059] The molar ratio of polyether polyol with a molecular weight of 400 (pentaerythritol as the initiator) and sodium is 1:1.05, the molecular weight of MPEG-Cl is 1000, and the molar ratio of MPEG-Cl to polyether polyol is 1.2:1 , the molar ratio of phosphorylation reagent to polyether polyol is 3.2:1. Weigh 200 parts of polyether polyol into a three-necked flask, slowly add 12 parts of metal sodium under nitrogen protection and stirring, raise the temperature to 130°C, and react for 3 hours. After the above reaction was completed, the temperature of the reaction system was lowered to 80° C., 600 parts of MPEG-Cl was added, and the reaction was continued for 6 hours. After the above reaction is completed, reduce the temperature of the reaction system to 50-70°C and maintain the temperature range, add 184.4 parts of phosphorylation r...

Embodiment 3

[0061] The synthesis process of polyether polyol with a molecular weight of 450 (xylitol as the initiator) is as follows: Weigh 152.2 parts of xylitol and 50-100 parts of ethylene glycol dimethyl ether, add them into the reactor and stir evenly, and then add 2.7 parts NaH, 297.8 parts of ethylene oxide was introduced under the condition of continuing to stir, and the temperature was raised to 80-120°C to carry out the reaction, and the reaction was stopped after the pressure of the system no longer decreased. Then distill under reduced pressure at 80-90°C to remove ethylene glycol dimethyl ether to obtain polyether polyol. The molecular weight measured by GPC is 458, and the molecular weight distribution is 1.04.

[0062]The molar ratio of polyether polyol with a molecular weight of 450 (xylitol is the initiator) and sodium is 1:1.15, the molecular weight of MPEG-Cl is 1000, and the molar ratio of MPEG-Cl to polyether polyol is 1.2 :1, the molar ratio of phosphorylation reage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com