Preparation method of clay mud inhibitor, as well as product and application thereof

A technology of mud inhibitor and clay, applied in the field of preparation of clay mud inhibitor, can solve the problems of uncontrollable setting time of concrete, slow adsorption rate, weak adsorption, etc., and achieve great application value, reduce sensitivity, and optimize performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

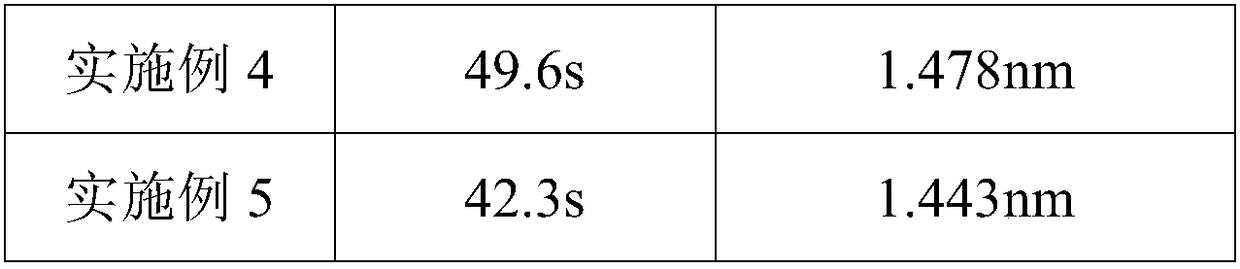

Examples

Embodiment 1

[0027] A kind of clay mud inhibitor, number average molecular weight is 3500, and its preparation method is as follows:

[0028] (1) Heating maleic rosin to 130°C and premixing polyethylene glycol with a molecular weight of 400 according to a molar ratio of 1:1.1, and performing an esterification reaction at a constant temperature of 155°C for 3 hours to obtain an intermediate product;

[0029] (2) adding anhydrous sodium carbonate to the intermediate product obtained in step (1), the quality of anhydrous sodium carbonate and the mol ratio of step (1) maleic rosin are 0.9:1, keep the temperature constant and continue to react for 6min to obtain clay Desilter.

Embodiment 2

[0031] A kind of clay mud inhibitor, number average molecular weight is 8000, and its preparation method is as follows:

[0032] (1) Heating maleic rosin to 170°C and premixing polyethylene glycol with a molecular weight of 6000 according to a molar ratio of 1:2.6, and performing an esterification reaction at a constant temperature of 180°C for 1 hour to obtain an intermediate product;

[0033] (2) adding anhydrous sodium carbonate to the intermediate product obtained in step (1), the quality of anhydrous sodium carbonate and the mol ratio of step (1) maleic rosin are 2.2:1, keep the temperature constant and continue to react for 20min to obtain clay Desilter.

Embodiment 3

[0035] A kind of clay mud inhibitor, number average molecular weight is 4850, and its preparation method is as follows:

[0036] (1) Heating maleic rosin to 140°C and premixing polyethylene glycol with a molecular weight of 4000 at a molar ratio of 1:1.8, and esterifying at a constant temperature of 165°C for 2.5 hours to obtain an intermediate product;

[0037] (2) adding anhydrous sodium carbonate to the intermediate product obtained in step (1), the quality of anhydrous sodium carbonate and the mol ratio of step (1) maleic rosin are 1.2:1, keep the temperature constant and continue to react for 8min to obtain clay Desilter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com