Automatic edge removal machine for rubber product

A technology of rubber products and edge removal machines, which is applied in the direction of using gaseous coolants for modification, cooling/ventilation/heating modification, electrical components, etc., which can solve the problems of low heat dissipation efficiency of equipment, low working stability, and unfavorable equipment use. , to achieve the effect of convenient movement, guaranteed performance and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

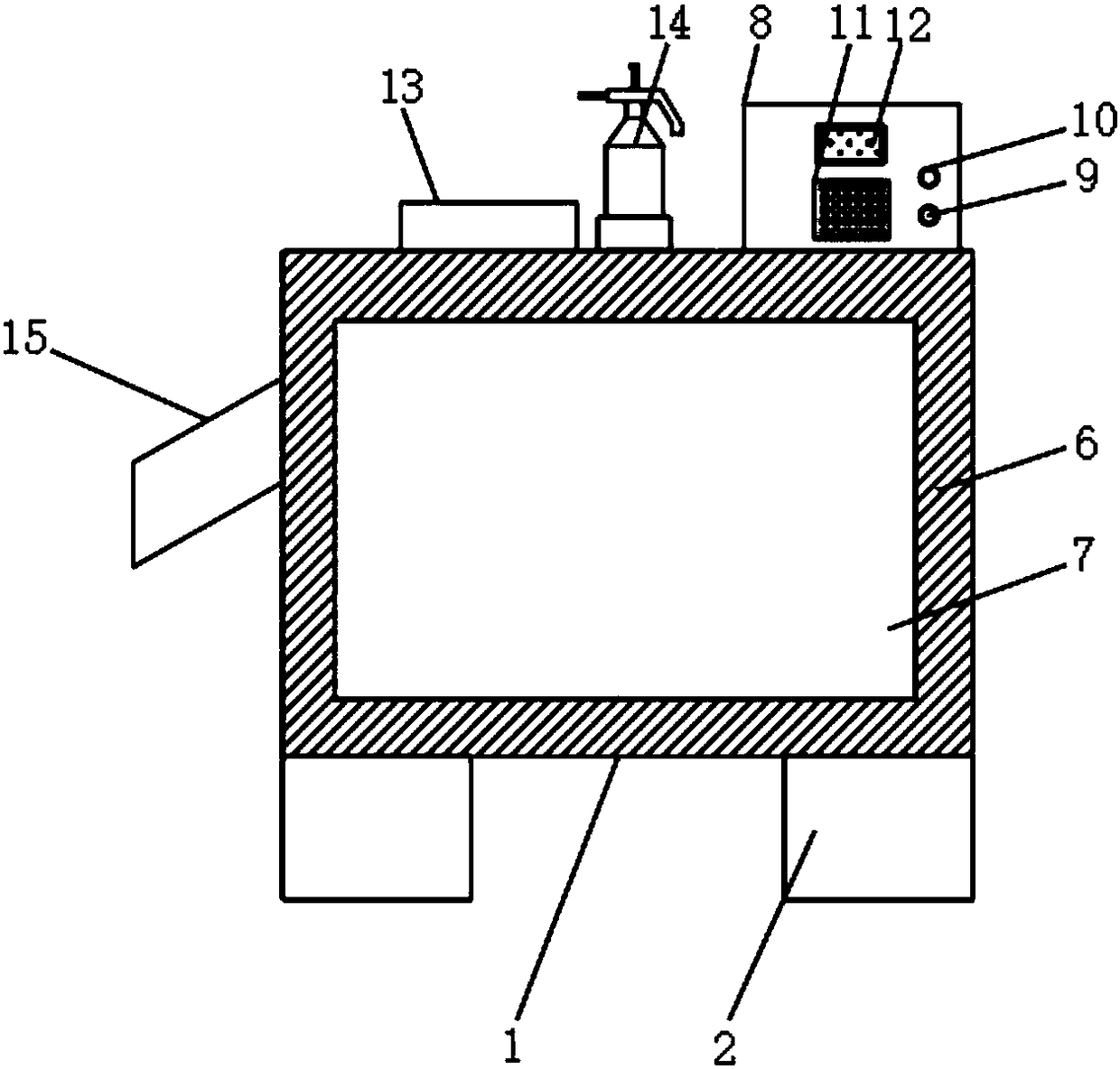

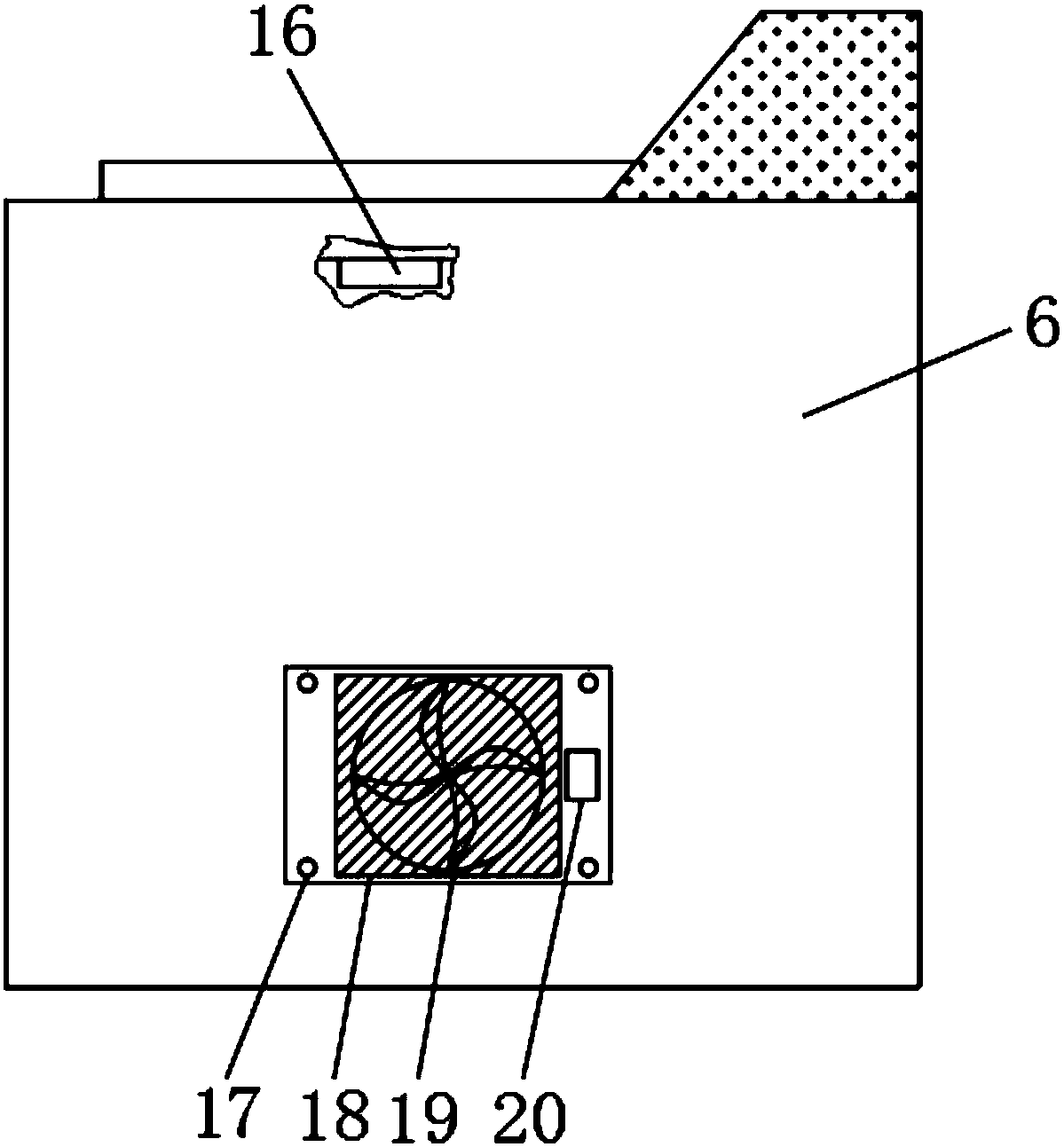

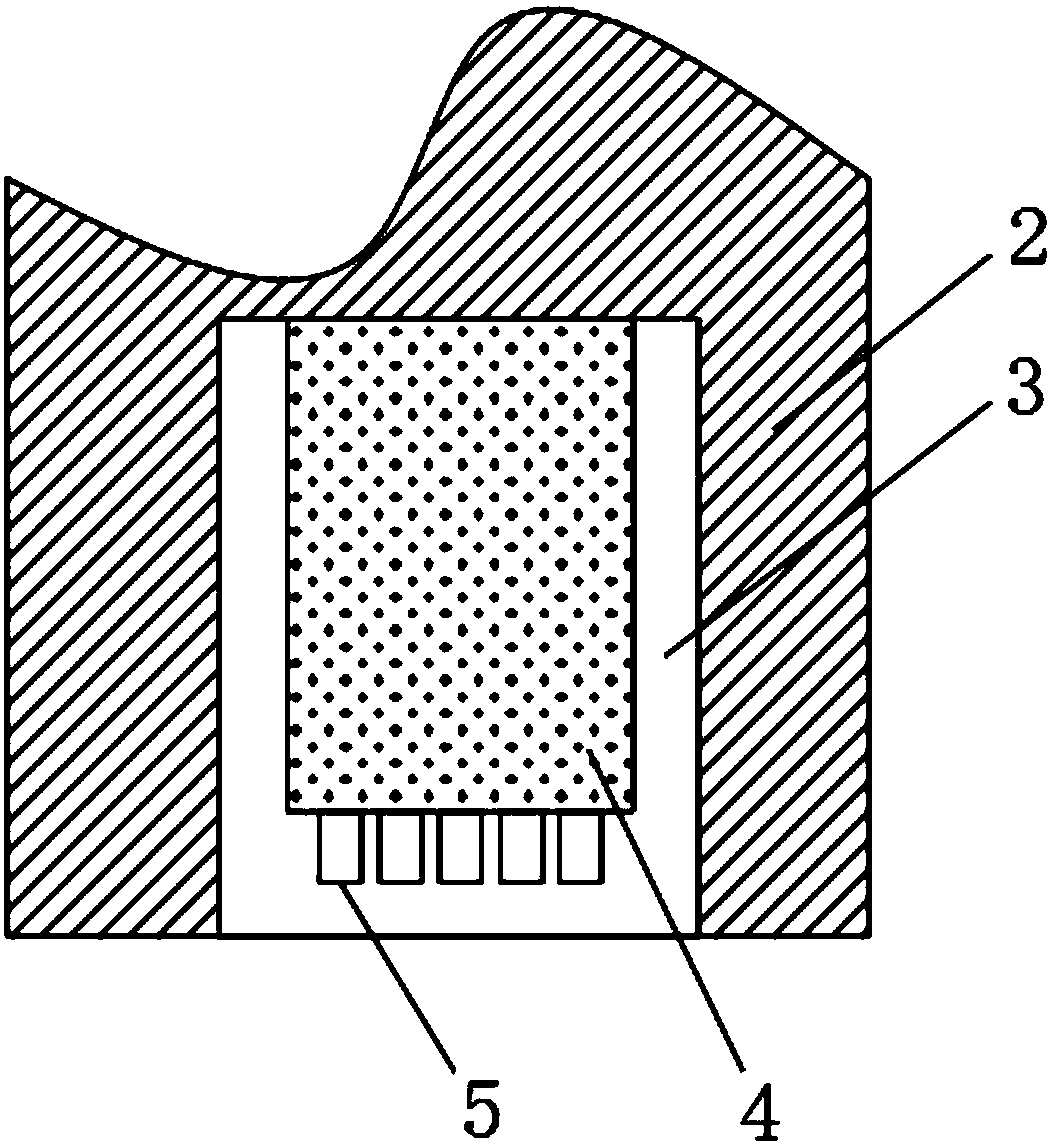

[0017] see Figure 1-3 , the present invention provides a technical solution: an automatic edge removal machine for rubber products, including an edge removal machine body 1, a leg 2, a groove 3, an electro-hydraulic rod 4, a pulley 5, a housing 6, a door 7, an electric Control box 8, power button 9, emergency stop button 10, TH6350 control panel 11, display screen 12, cylinder body 13, water spray bottle 14, discharge port 15, temperature sensor 16, fixing bolt 17, dust-proof net 18, cooling fan 19 and PLC controller 20, the bottom end of the edge removal machine body 1 is equipped with a leg 2, the inside of the leg 2 is provided with a groove 3, the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com