Waste paper treatment device for carton green printing

A processing device and waste paper technology, which is applied in paper/cardboard containers, packaging, papermaking, etc., can solve problems such as leftovers sticking, adhesive cannot be coated normally, and carton surface cleanliness is poor, so as to achieve the effect of high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

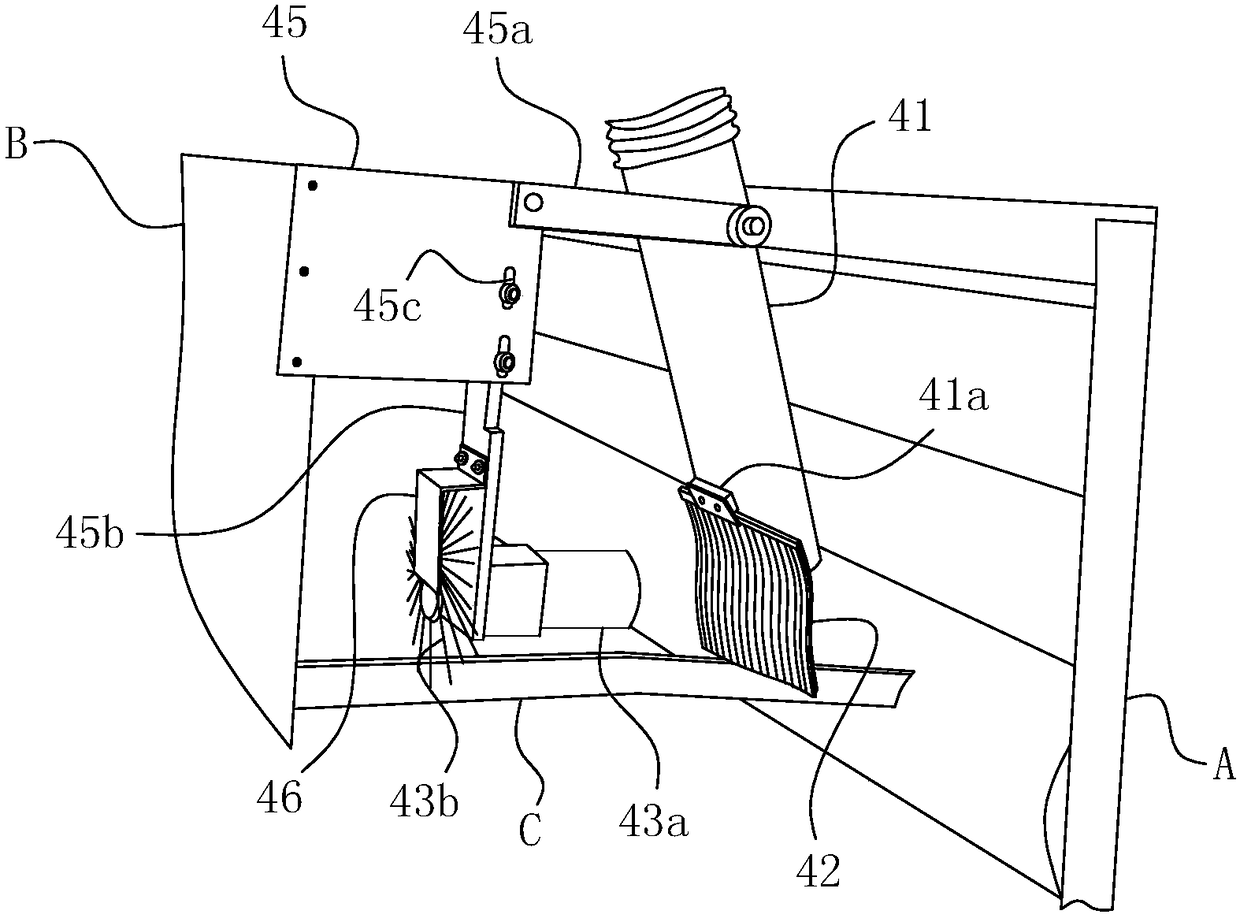

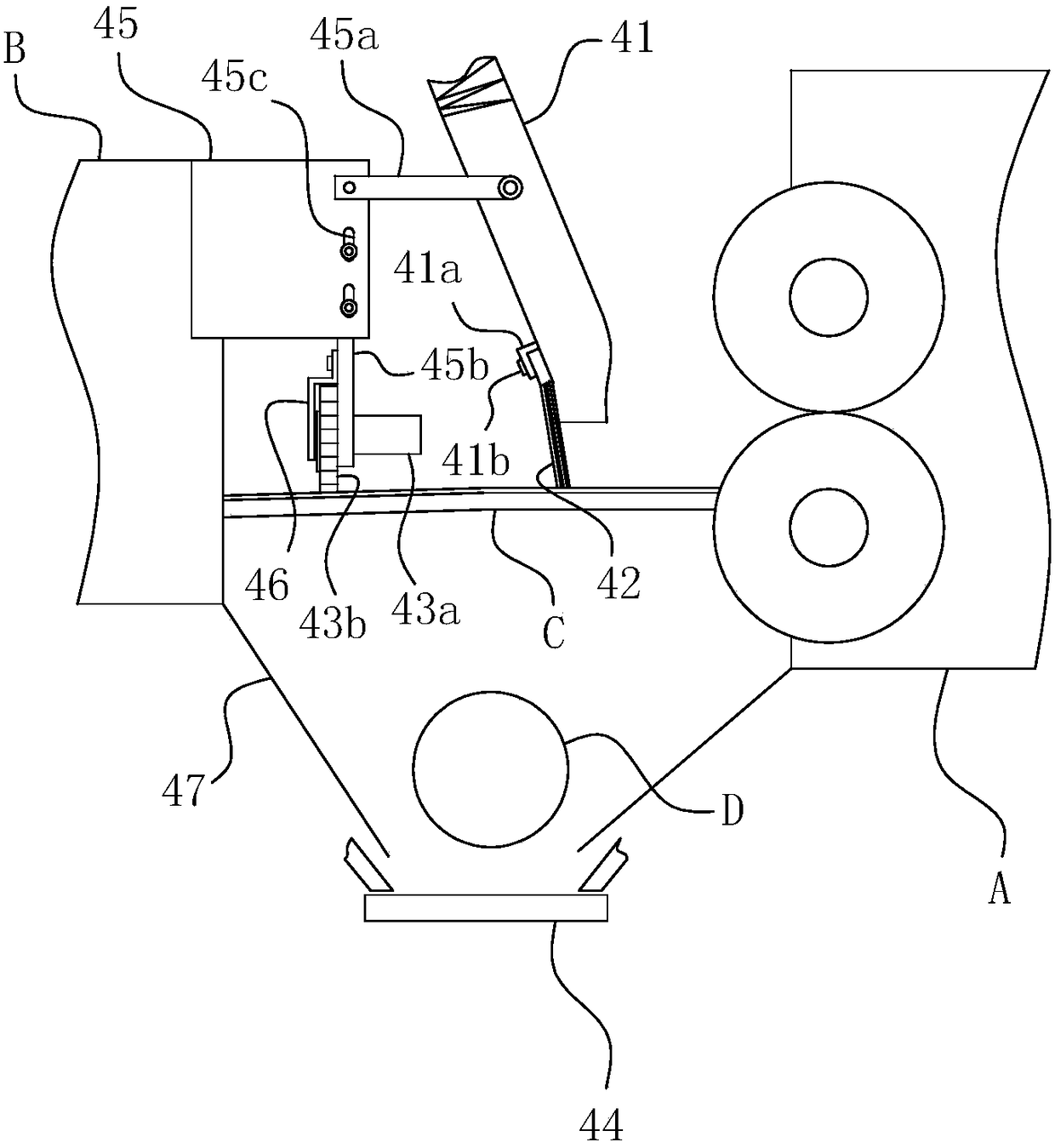

[0026] For ease of understanding, here in conjunction with accompanying drawing, the concrete structure of the present invention and working mode are further described as follows:

[0027] The specific structure of the present invention refers to Figure 1-2 As shown, it is arranged between the printing machine A and the splicing machine B of the existing printing production line. The structure of the present invention includes a fixing assembly, a blowing assembly and a dusting assembly, wherein:

[0028] The blowing assembly includes an air duct 41 and a cleaning broom 42. The air duct 41 is drawn from an external air supply device, and the air outlet of the air duct 41 points to the discharge guide rail C between the printing machine A and the splicer B. The air duct 41 is fixed on the fixed plate 45 by the horizontal rod 45a, and the fixed plate 45 forms a fixed connection between the frames at the feeding port of the paper splicer B. The dust-cleaning broom 42 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com