Numerical control grinding machine motorized spindle capable of automatically adjusting bearing pretightening force

A bearing preload, CNC grinding machine technology, applied in the direction of manufacturing tools, metal processing equipment, grinding machine parts, etc., can solve the problems of low machining accuracy, thermal deformation of bearings, unadjustable spring preload, etc., to achieve optimization Cooling and lubricating structure, ensuring support accuracy, reducing the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

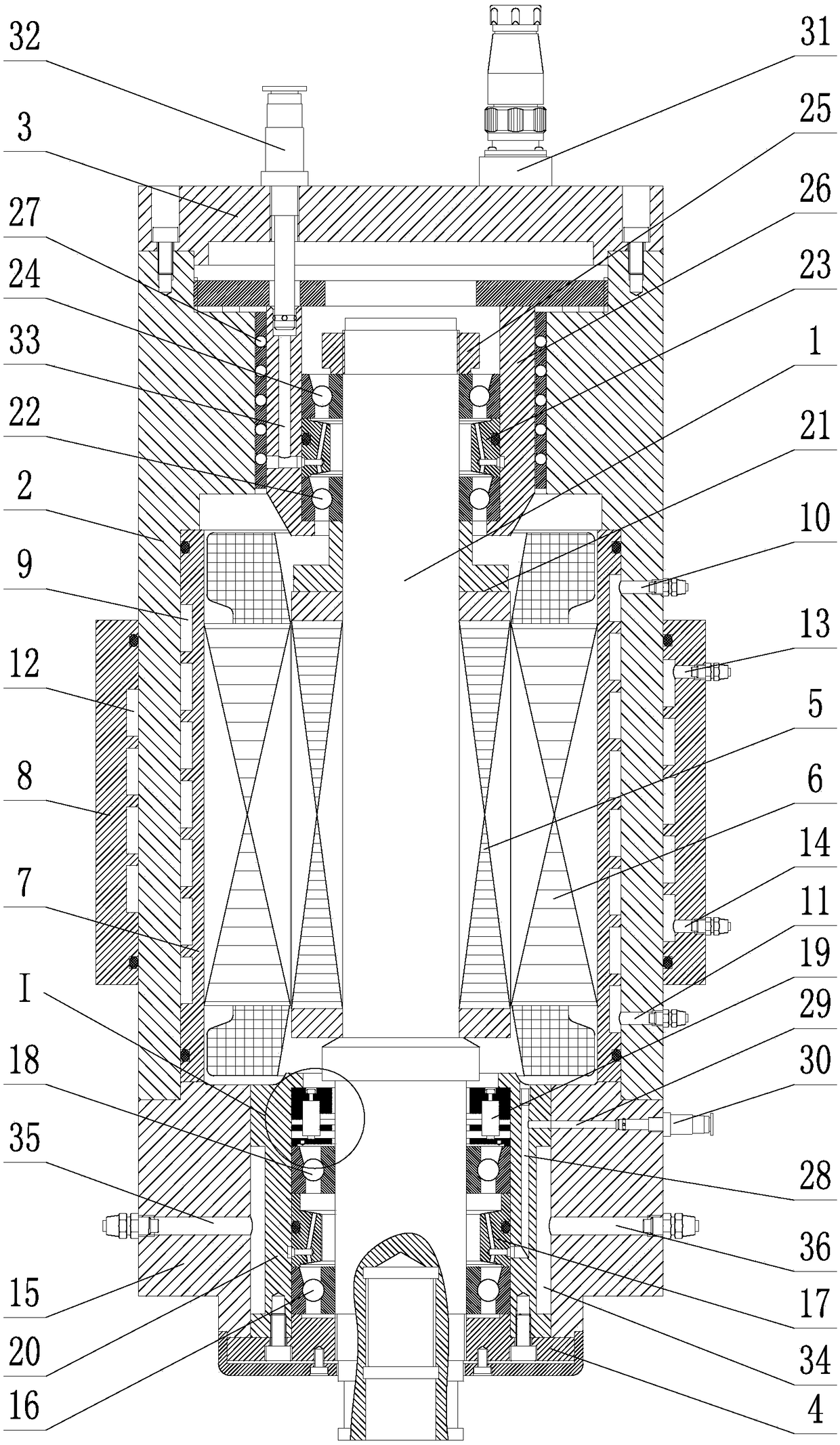

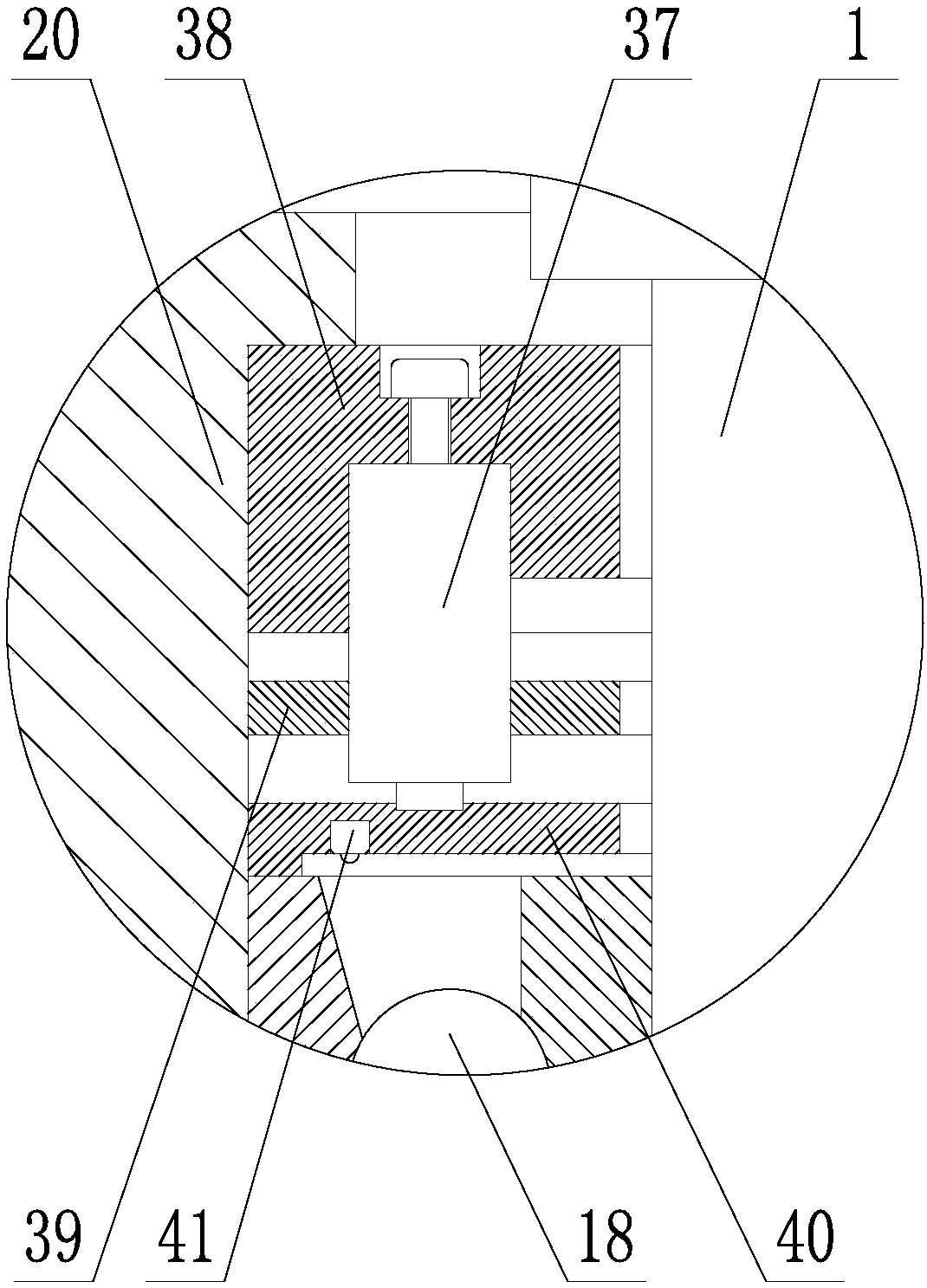

[0016] Such as figure 1 , 2 As shown, a CNC grinding machine electric spindle with automatic adjustment of bearing pretightening force includes a spindle 1, a housing 2, an upper end cover 3, a lower end cover 4, a rotor coil 5 and a stator coil 6; the rotor coil 5 is fixedly set on In the middle of the main shaft 1, the stator coil 6 is fixedly installed on the inner surface of the housing 2, and a first cooling water jacket 7 is installed between the stator coil 6 and the housing 2, at the axial position of the first cooling water jacket 7 The outer surface of the shell 2 is equipped with a second cooling water jacket 8; a first spiral cooling water channel 9 is arranged in the first cooling water jacket 7, and the first spiral cooling water channel water inlet 10 and the first spiral cooling water channel outlet The water ports 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com