Ultrasonic knife handle with electrodes

A tool holder and ultrasonic technology, which is applied in the field of ultrasonic tool holders, can solve problems such as leakage, easy pollution of dust, and non-waterproof, etc., to achieve the effects of tool change, surface quality improvement, and cutting force reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

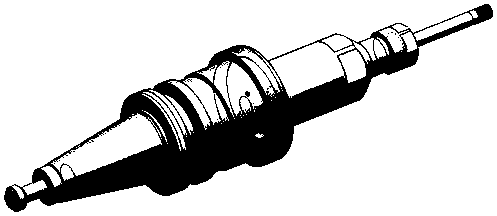

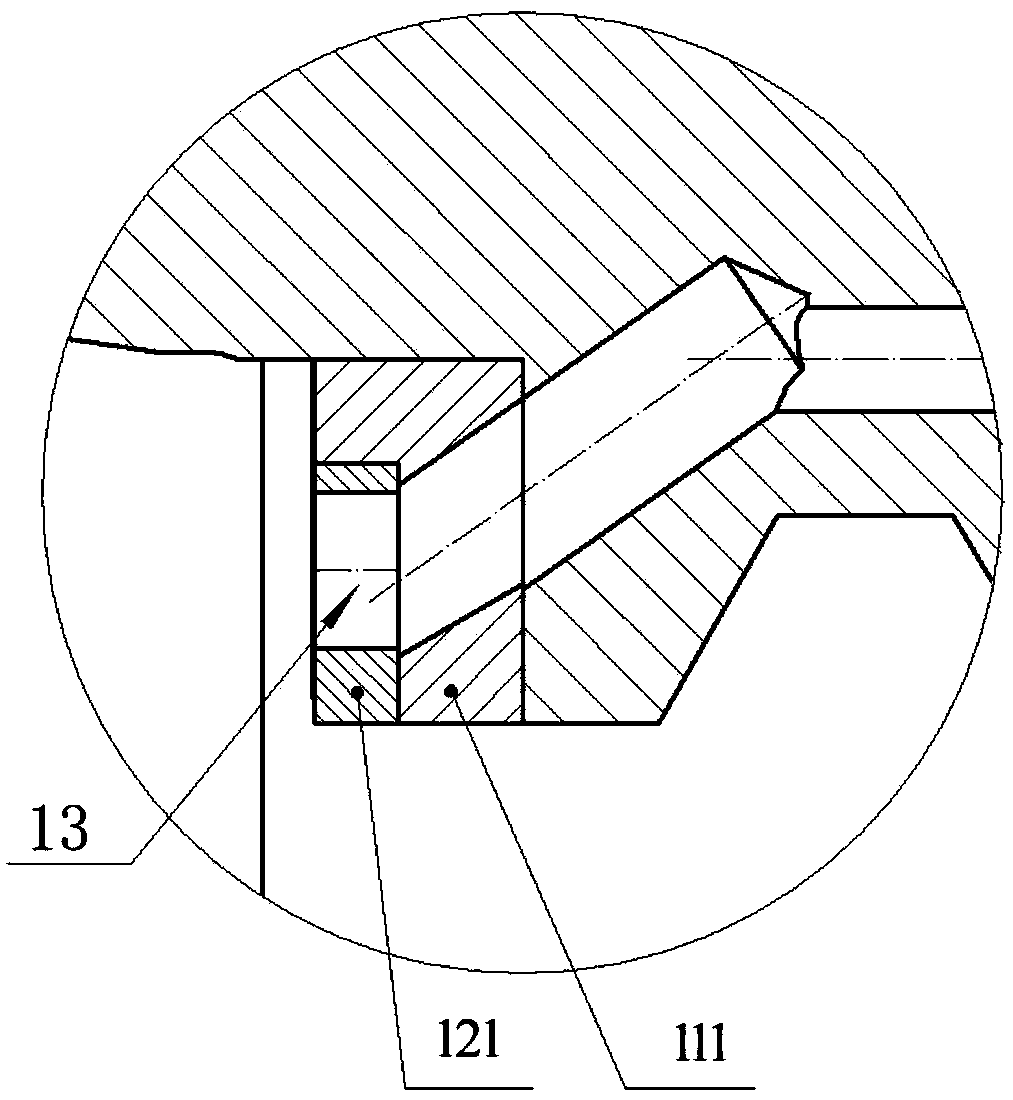

[0026] This embodiment provides an ultrasonic knife handle with electrodes. figure 1 Shown is the ultrasonic tool holder with electrodes of the present invention connected with the CNC machine tool spindle 1, and image 3 A three-dimensional appearance view of the ultrasonic tool holder with electrodes of the present invention that is not connected with the spindle 1 of the CNC machine tool is shown. Such as figure 1 As shown, the ultrasonic knife holder with electrodes of the present invention is composed of a knife holder 2 and a transducer, and the transducer is composed of a horn 7, two piezoelectric ceramics 5, a transducer pressing block 4, and a compression screw 3 components, the transducer as a whole and the tool handle 2 adopt an interference fit, and are press-fitted into one body by extrusion, and the compression screw 3 is sequentially connected to the transducer pressing block 4, piezoelectric ceramics 5 and horn 7 , and the connection is fastened through the h...

Embodiment 2

[0032] This embodiment provides a replaceable ultrasonic knife handle with electrodes.

[0033] The difference from Embodiment 1 is that in this embodiment, the insulating sleeve 11 is made of plastic material, the conductive sheet 12 is a conductive nickel sheet, and there are 4 piezoelectric ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com