A kind of go/sio 2 Preparation method of modified nanocomposite film

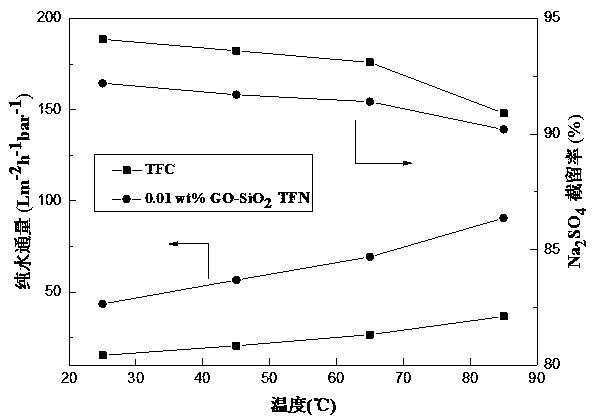

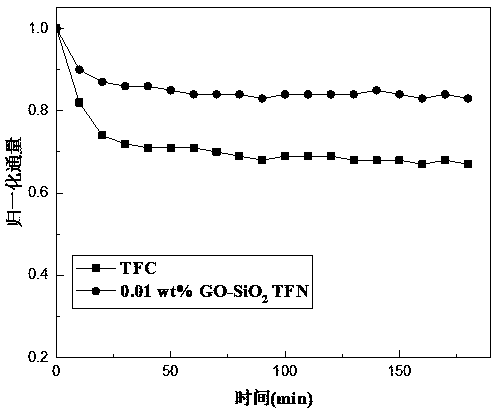

A nano-composite and thin-film technology, applied in the field of nano-composite thin film preparation, can solve the problems of easy agglomeration and easy pollution of NF membrane, and achieve the effects of enhanced thermal stability, increased hydrophilicity, and good thermo-mechanical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

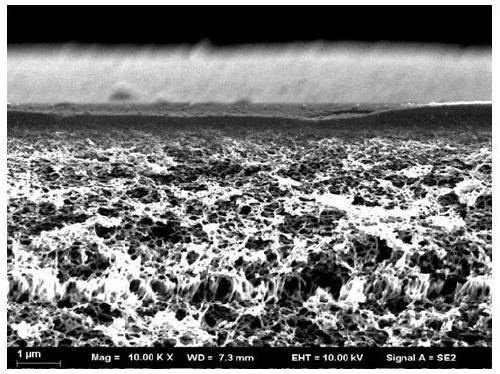

Image

Examples

Embodiment 1

[0031] (1) Preparation of polysulfone ultrafiltration membrane:

[0032]Mix 18g PSF and 2g PVP in 80g DMF respectively, stir the blended system at 60°C for 5h to dissolve into a homogeneous solution, and let it stand at room temperature for 12h to defoam to obtain a casting solution. Use a self-made scraper to scrape the casting solution on the glass plate to form a film by casting method, and quickly put it into the prepared coagulation bath for phase separation and forming (the ratio of the coagulation bath is: distilled water 2000g, dodecyl SDS5g, DMF20g ), after soaking for 30min, take it out and rinse with a large amount of distilled water, and store it in distilled water. The thickness of the prepared PSF ultrafiltration membrane is about 200 μm. The rejection rate of the prepared PSF ultrafiltration membrane is more than 90%, reaching the standard of ultrafiltration membrane.

[0033] Among them, PVP is used as a porogen; SDS in the coagulation bath is used as a surfa...

Embodiment 2

[0039] (1) Preparation of polysulfone ultrafiltration membrane:

[0040] Mix 18g PSF and 2g PVP in 80g DMF respectively, stir the blended system at 60°C for 5h to dissolve into a homogeneous solution, and let it stand at room temperature for 12h to defoam to obtain a casting solution. Use a self-made scraper to scrape the casting solution on the glass plate to form a film by casting method, and quickly put it into the prepared coagulation bath for phase separation and forming (the ratio of the coagulation bath is: distilled water 2000g, dodecyl SDS5g, DMF20g ), after soaking for 30min, take it out and rinse with a large amount of distilled water, and store it in distilled water. The thickness of the prepared PSF ultrafiltration membrane is about 200 μm. The rejection rate of the prepared PSF ultrafiltration membrane is more than 90%, reaching the standard of ultrafiltration membrane.

[0041] (2) Preparation of graphene oxide / silica composite nanomaterials (GO / SiO 2 ):

[...

Embodiment 3

[0048] (1) Preparation of polysulfone ultrafiltration membrane:

[0049] Take 15g PSF and 5g PVP and mix them in 80g DMF respectively, stir the blended system at 60°C for 5h to dissolve into a homogeneous solution, and let it stand at room temperature for 12h to defoam to obtain a casting solution. Use a self-made scraper to scrape the casting solution on the glass plate to form a film by casting method, and quickly put it into the prepared coagulation bath for phase separation and forming (the ratio of the coagulation bath is: distilled water 2000g, dodecyl SDS5g, DMF20g ), after soaking for 30min, take it out and rinse with a large amount of distilled water, and store it in distilled water. The thickness of the prepared PSF ultrafiltration membrane is about 100 μm. The rejection rate of the prepared PSF ultrafiltration membrane is more than 90%, reaching the standard of ultrafiltration membrane.

[0050] (2) Preparation of graphene oxide / silica composite nanomaterials (GO / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com