Making method of freeze-dried seven-kind fish balls

A technology for drying seven-star fish and fish balls, which is applied to the preparation field of freeze-dried seven-star fish balls, can solve the problems of light flavor, yellowish color, heavy fishy smell and the like, and achieves the effects of fresh and smooth taste, scientific proportion and delicious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method for freeze-dried seven-star fish balls, comprising the steps of:

[0026] (1) Select 7 kinds of fresh freshwater fish, silver carp: catfish: grass carp: snakehead carp: bighead carp: herring: tilapia, remove the internal organs of the fish, wash, peel, bone, and meat;

[0027] (2) Soak the fish in pure water at 4°C for more than 8 hours, remove and drain;

[0028] (3) According to 100 parts by mass of catfish: grass carp: black carp: bighead carp: herring: tilapia = 3:2:1:1:1:1:1 mixed fish meat, put it into a beater at 4 ° C, beat 6min, the speed is 330rpm, add 10 parts by mass of frozen egg white and continue beating for 3min, the speed is 400rpm; continue to add 30 parts by mass of a mixture of cornstarch and yam powder, the mixing ratio is 1:1, and continue beating;

[0029] (4) Add the above mixed fish mixture to the mixed seasoning and mix well;

[0030] (5) Inject minced meat into the filling through the machine;

[0031] (6) Put the stuff...

Embodiment 2

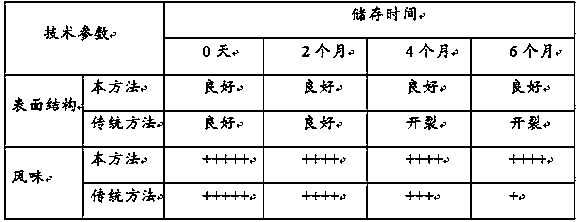

[0039] The freeze-dried fish balls of Example 1 were stored at normal temperature for 6 months, the surface structure was observed every month, and the product flavor was measured with the PEN3 model electronic nose of the German AIRSENSE company. The fish balls made by this method had no flavor after 6 months. Compared with freshwater fish balls that do not use this method, the flavor loss is serious (see the table below for data).

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com