A polymer lithium ion battery for high energy density mobile power supply

A high-energy-density, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of affecting the service life of the battery, the battery is easy to bloat, and the battery price is high, so as to reduce the phenomenon of fragmentation, increase flexibility, The effect of shortening the batching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

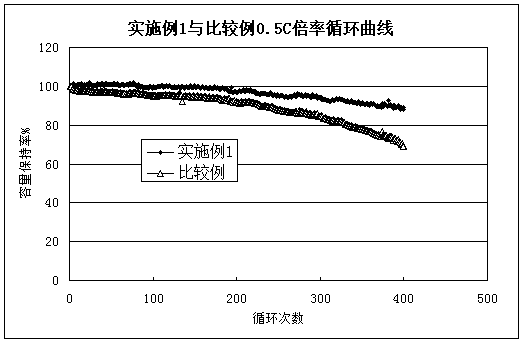

Embodiment 1

[0042] A kind of high energy density polymer lithium ion battery of the present embodiment, its preparation comprises the following steps:

[0043] (1) Preparation of positive electrode sheet:

[0044] The mass percentage of each component of the positive electrode is positive active material: carbon nanotube: KS-6 (conductive graphite): PVDF (polyvinylidene fluoride) = 97.8:0.5:0.4:1.3, as follows:

[0045] A. Add polyvinylidene fluoride and N-methylpyrrolidone into the high-speed shear disperser at a ratio of 0.08:1, the vacuum degree is -0.09MPa, the revolution is 70rmp, the rotation is 2400rmp, and the adhesive glue is obtained by stirring for 120min;

[0046] B. Add carbon nanotube conductive agent and micron-sized conductive graphite KS-6 into the glue solution, the vacuum degree is -0.09MPa, the revolution is 70rmp, the rotation is 2400rmp, and the stirring is 90min to obtain the nano-micron composite conductive agent;

[0047] C. Add 50% of the total amount of high-vo...

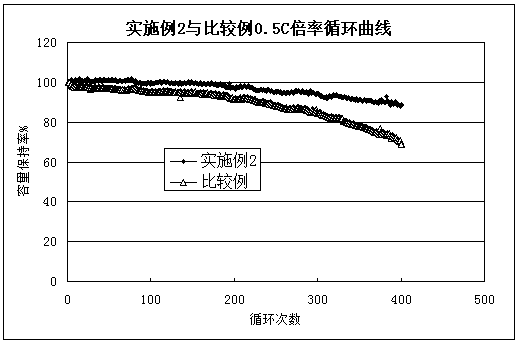

Embodiment 2

[0062] A kind of high energy density polymer lithium ion battery of the present embodiment, its preparation comprises the following steps:

[0063] (1) Preparation of positive electrode sheet:

[0064] The mass percentage of each component of the positive electrode is positive active material: carbon nanotube: KS-6 (conductive graphite): PVDF (polyvinylidene fluoride) = 96.8:0.8:0.7:1.7, as follows:

[0065] A. Add polyvinylidene fluoride and N-methylpyrrolidone into the high-speed shear disperser at a ratio of 0.08:1, the vacuum degree is -0.10MPa, the revolution is 60rmp, the rotation is 2300rmp, and the adhesive glue is obtained by stirring for 90min;

[0066] B. Add carbon nanotube conductive agent and micron-sized conductive graphite KS-6 into the glue solution, the vacuum degree is -0.10MPa, the revolution is 60rmp, the rotation is 2300rmp, and the stirring is 120min to obtain the nano-micron composite conductive agent;

[0067] C. Add 50% of the total amount of high-vo...

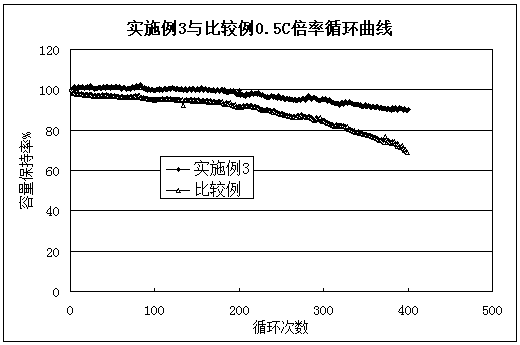

Embodiment 3

[0082] A kind of high energy density polymer lithium ion battery of the present embodiment, its preparation comprises the following steps:

[0083] (1) Preparation of positive electrode sheet:

[0084] The mass percentage of each component of the positive electrode is positive active material: carbon nanotube: KS-6 (conductive graphite): PVDF (polyvinylidene fluoride) = 96.0:1.3:1.0:1.7, as follows:

[0085] A. Add polyvinylidene fluoride and N-methylpyrrolidone into the high-speed shear disperser at a ratio of 0.08:1, the vacuum degree is -0.08MPa, the revolution is 65rmp, the rotation is 2500rmp, and the adhesive glue is obtained by stirring for 105min;

[0086] B. Add carbon nanotube conductive agent and micron-sized conductive graphite KS-6 into the glue solution, the vacuum degree is -0.08MPa, the revolution is 65rmp, the rotation is 2500rmp, and the stirring is 105min to obtain the nano-micron composite conductive agent;

[0087] C. Add 50% of the total amount of high-v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com