Pharmaceutical intermediate 2,5-dichlorobenzoic acid synthesis method

A technology for the synthesis of dichlorobenzoic acid and its synthesis method is applied in the field of synthesis of pharmaceutical intermediate 2,5-dichlorobenzoic acid, which can solve the problems of low final yield and complicated process, shorten the reaction time and reduce intermediate link, the effect of improving the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

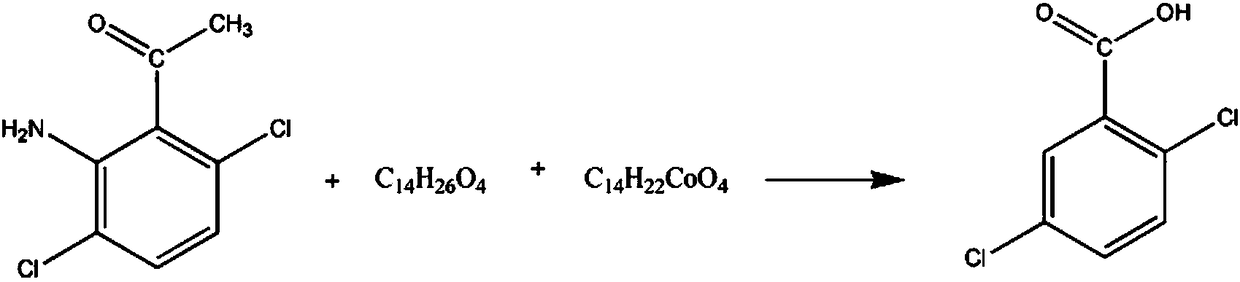

Image

Examples

example 1

[0010] Add 2mol of 2,5-dichloro-6-aminobenzoic acid and 3mol mass fraction of 70% diisobutyl adipate solution in the reaction vessel, raise the solution temperature to 70°C, control the stirring speed to 130rpm, divide Add 3 mol of cobalt naphthenate 3 times, the interval between each time is 30min, continue the reaction for 90min, add 1200ml of potassium chloride solution with a mass fraction of 15%, the solution is layered, reduce the solution temperature to 10°C, and add a mass fraction of 20 % oxalic acid solution to adjust pH to 4, mass fraction is 10% potassium sulfate solution washing, mass fraction is 80% methyl tert-butyl ether solution washing, mass fraction is 90% 2-methyltetrahydrofuran solution washing, 15kPa Distilled under reduced pressure, collected fractions at 110°C, and dehydrated with anhydrous sodium sulfate dehydrating agent to obtain 351.44 g of finished product 2,5-dichlorobenzoic acid with a yield of 92%.

example 2

[0012] Add 2mol of 2,5-dichloro-6-aminobenzoic acid and 4mol mass fraction of 73% diisobutyl adipate solution in the reaction vessel, raise the solution temperature to 75°C, control the stirring speed to 140rpm, divide Add 3.5mol of cobalt naphthenate 4 times, each interval is 35min, continue to react for 110min, add 1200ml of potassium chloride solution with a mass fraction of 18%, the solution is layered, reduce the solution temperature to 12°C, add a mass fraction of 22% oxalic acid solution to adjust pH to 4.5, mass fraction is 14% potassium sulfate solution washing, mass fraction is 80% methyl tert-butyl ether solution washing, mass fraction is 93% 2-methyltetrahydrofuran solution washing, Distilled under reduced pressure at 18kPa, collected fractions at 115°C, and dehydrated with a dehydrating agent to obtain 359.08g of finished product 2,5-dichlorobenzoic acid with a yield of 94%.

example 3

[0014] Add 2mol of 2,5-dichloro-6-aminobenzoic acid and 5mol mass fraction of 76% diisobutyl adipate solution in the reaction vessel, raise the solution temperature to 78°C, control the stirring speed to 160rpm, divide Add 4 mol of cobalt naphthenate 5 times, the interval between each time is 40min, continue the reaction for 120min, add 1200ml of potassium chloride solution with a mass fraction of 22%, the solution is layered, reduce the temperature of the solution to 15°C, and add a mass fraction of 25% % oxalic acid solution to adjust pH to 5, mass fraction is 18% potassium sulfate solution washing, mass fraction is 85% methyl tert-butyl ether solution washing, mass fraction is 96% 2-methyltetrahydrofuran solution washing, 20kPa minus Pressure distillation, collecting fractions at 120°C, and dehydrating with a dehydrating agent, yielded 370.54 g of finished product 2,5-dichlorobenzoic acid with a yield of 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com