3D (Three-dimensional) printing device for printing buildings

A 3D printing and ceramsite technology, which is used in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problem that the uniformity of concrete cannot be guaranteed, the integrity of the layered structure wall is poor, and the amount of concrete extrusion is difficult to control. and other problems, to ensure the integrity and stability, facilitate later decoration, and ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

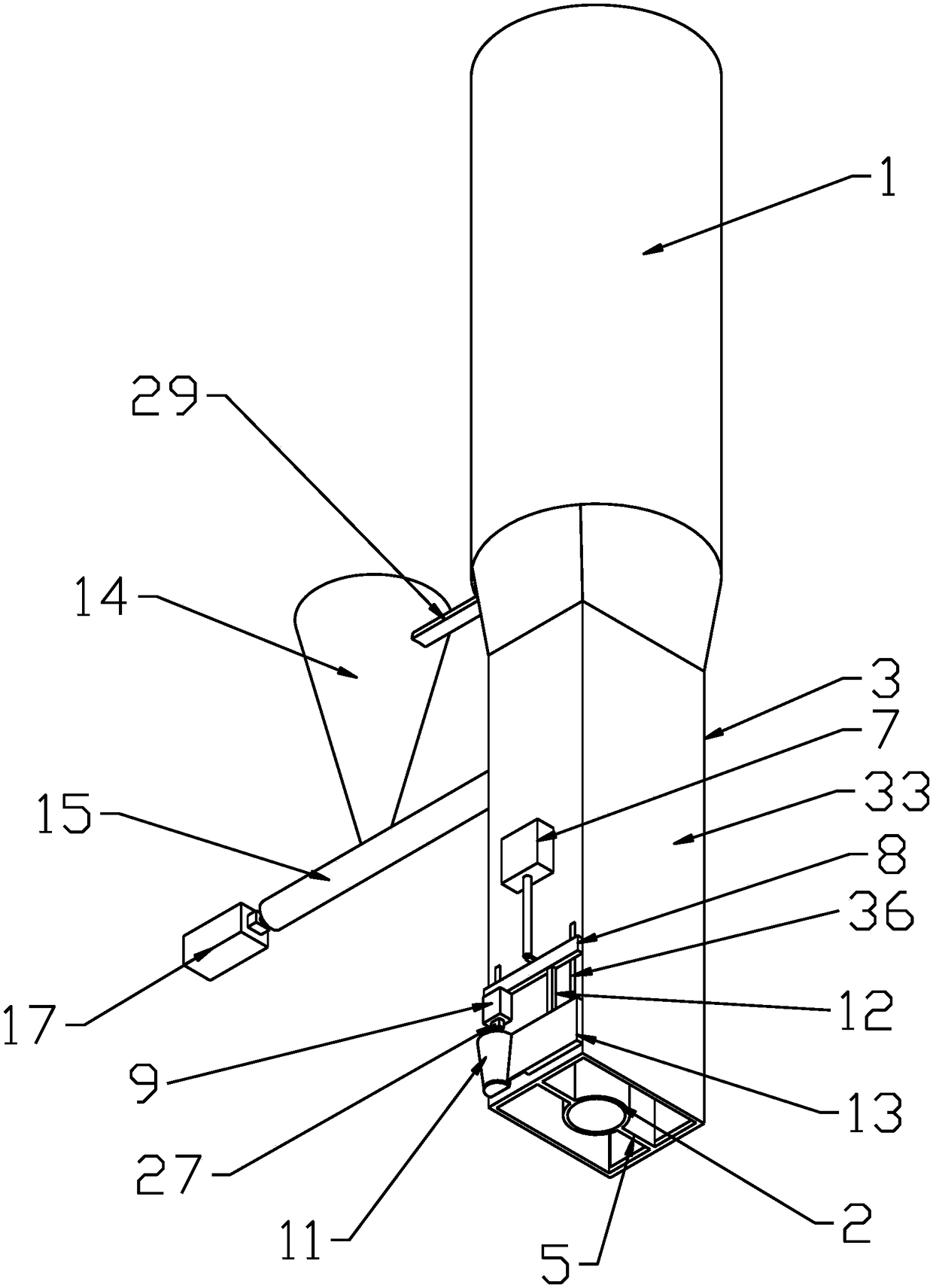

[0035] Below in conjunction with accompanying drawing and embodiment the technical scheme of the invention is further described:

[0036] Such as Figure 1 to Figure 10 As shown, a 3D printing construction device includes a spray head 1 and a smoothing mechanism 30, wherein it also includes a ceramsite conveying mechanism, a screw drive device 4 is provided in the spray head 1, and the screw drive device 4 includes The screw driving rod 41 and the motor d42, the motor d42 is connected with the transmission d43, the speed changer d43 is connected with the upper end of the screw driving rod 41, the lower end of the spray head 1 is provided with the nozzle 3, and the lower end of the screw driving rod 41 extends to the nozzle 3, and the nozzle 3 is connected by the opposite It is surrounded by two parallel end plates and two opposite side plates 31, the two end plates are perpendicular to the movement direction of the nozzle 3, and the two end plates are provided with multiple The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com