Light spot changing mechanism and 3D printing equipment provided with light spot changing mechanism

A technology of changing the light spot and adjusting the mechanism, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of slow forming speed, restricting the speed and low efficiency of 3D printing rapid prototyping, and achieve the offset of focus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

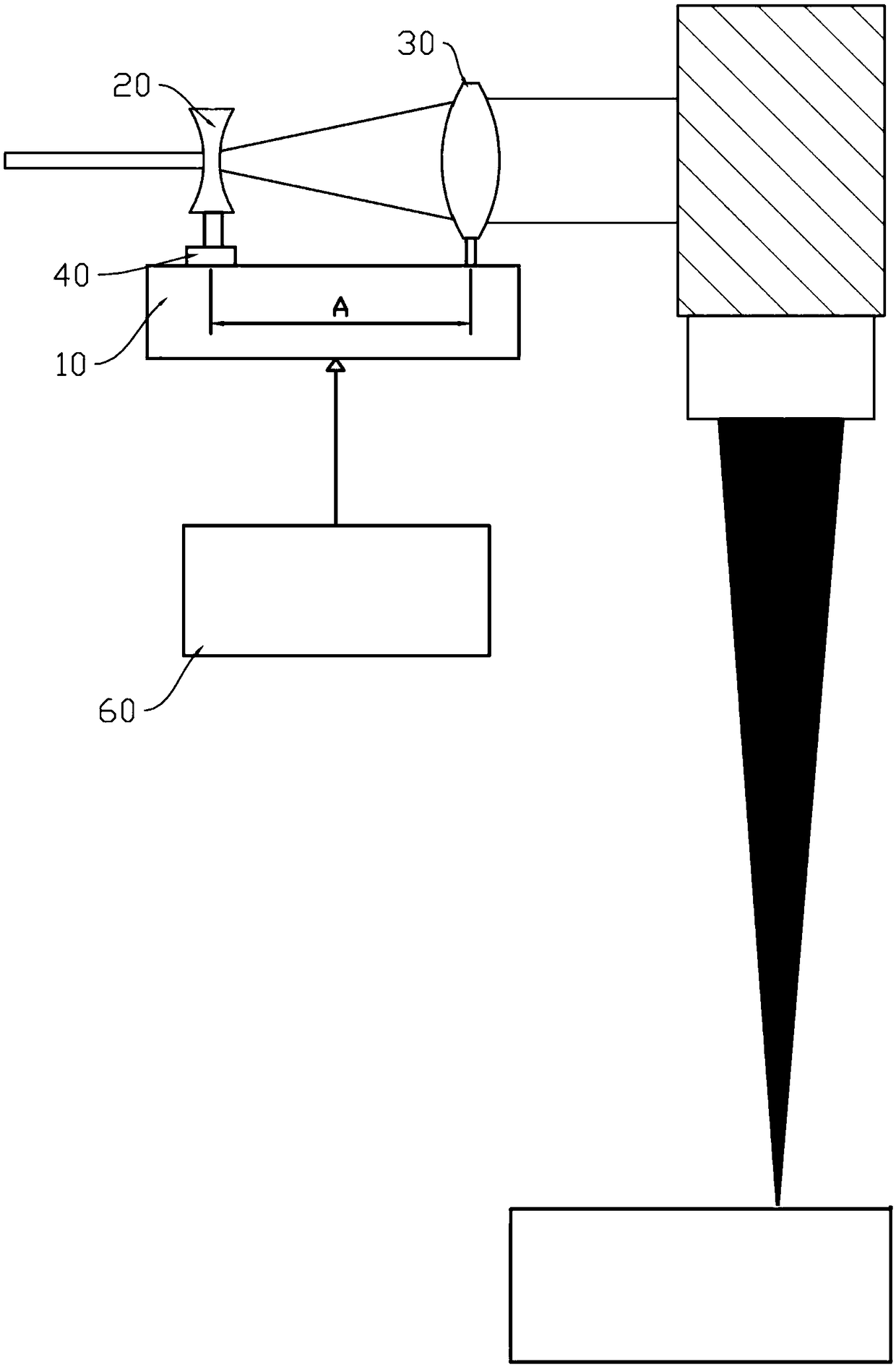

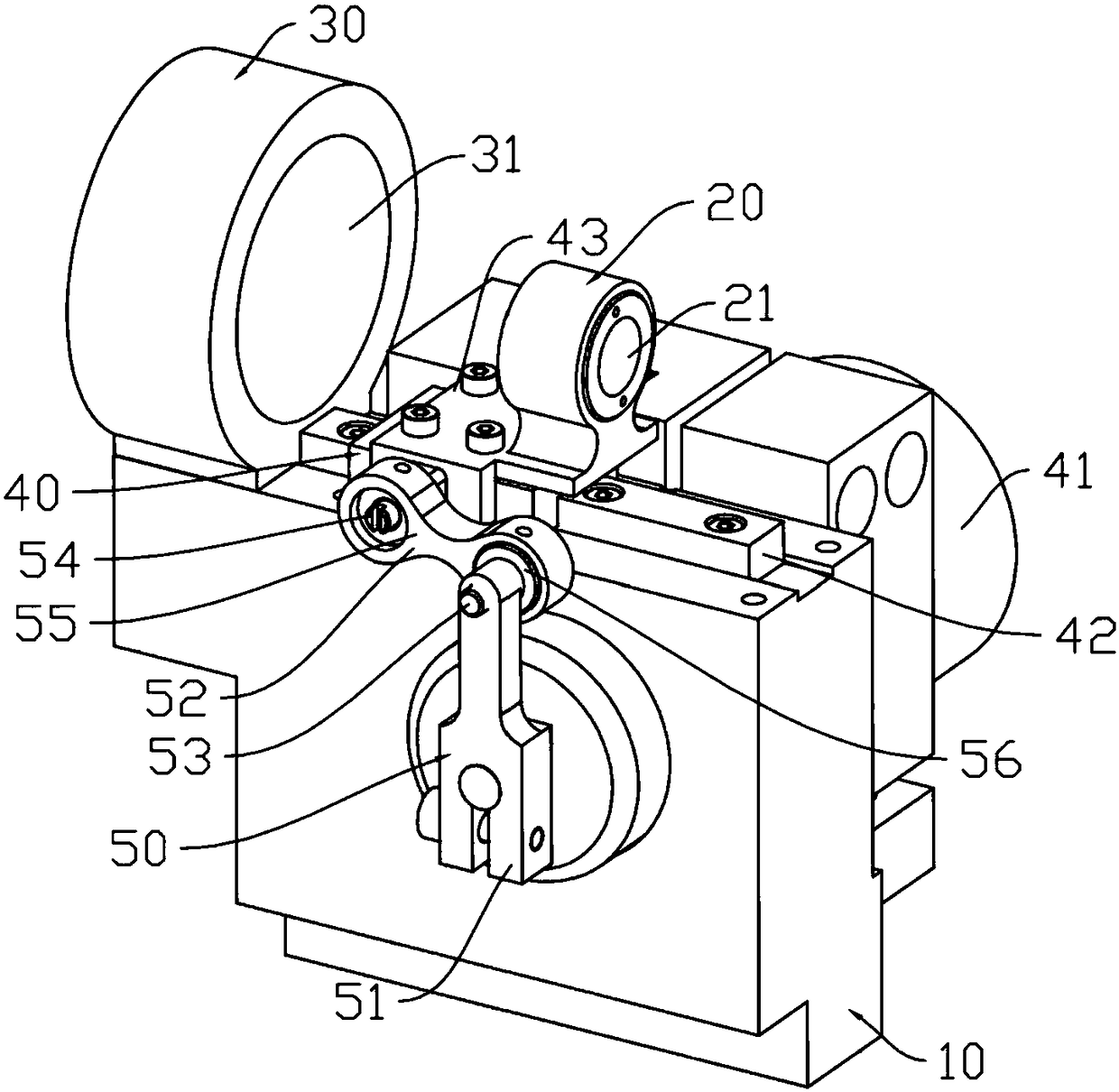

[0024] Such as figure 1 , figure 2 As shown, a 3D printing equipment facula variable mechanism includes a base 10 on which a first optical lens group 21, a second optical lens group 31 and an adjustment mechanism 40 are arranged. The adjustment mechanism 40 includes a power device 41, a transmission device 50. The guide rail 42 and the adjustment block 43 arranged on the guide rail 42, the power device is connected with the transmission device, the transmission device is connected with the adjustment block, the adjustment block is connected with the first optical lens group, and the power device drives the transmission device to drive the adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com