Fly ash mercury removal device and mercury removal method

A fly ash and mercury removal technology, which is applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of cyclic accumulation of mercury concentration in fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

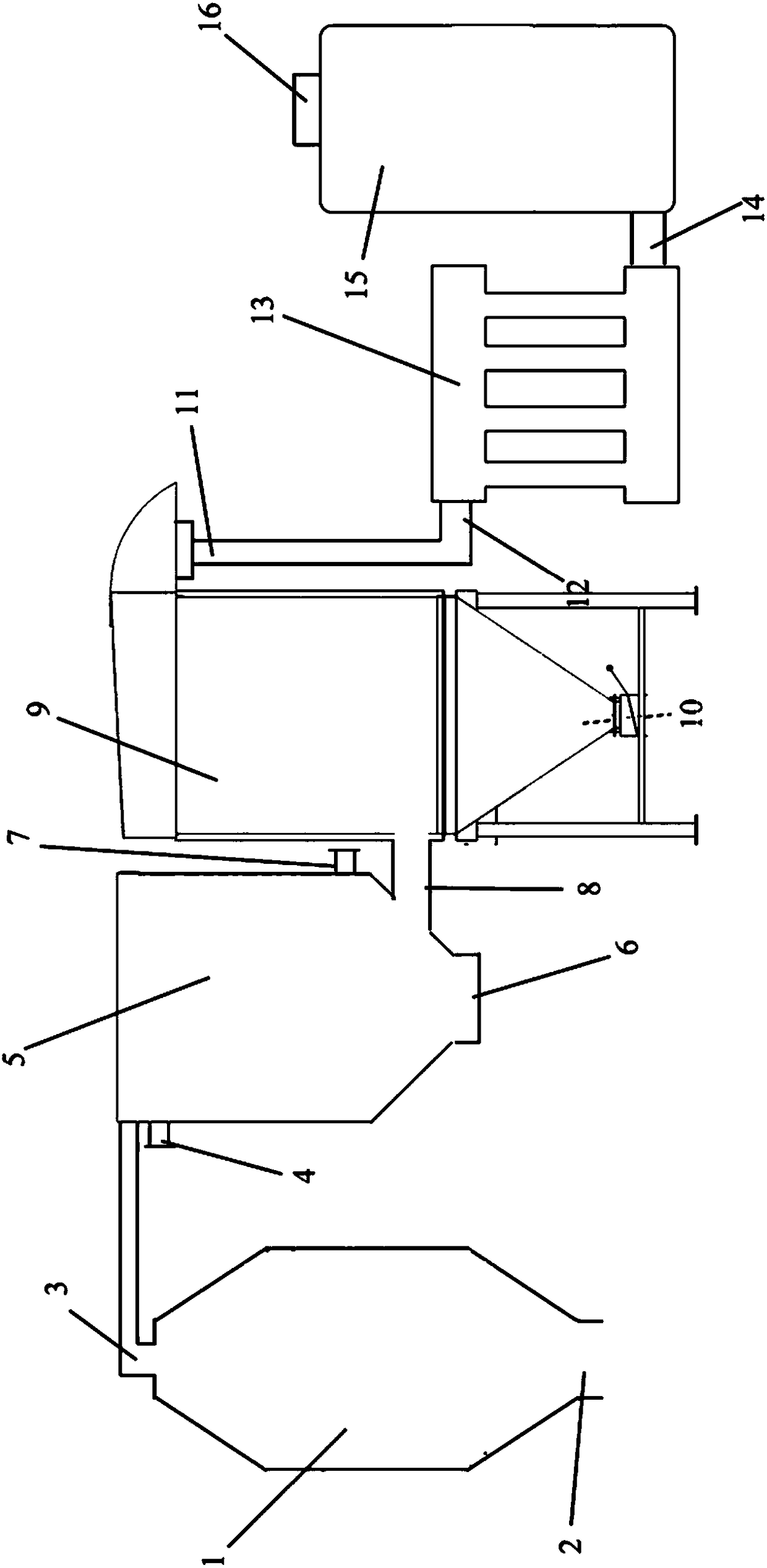

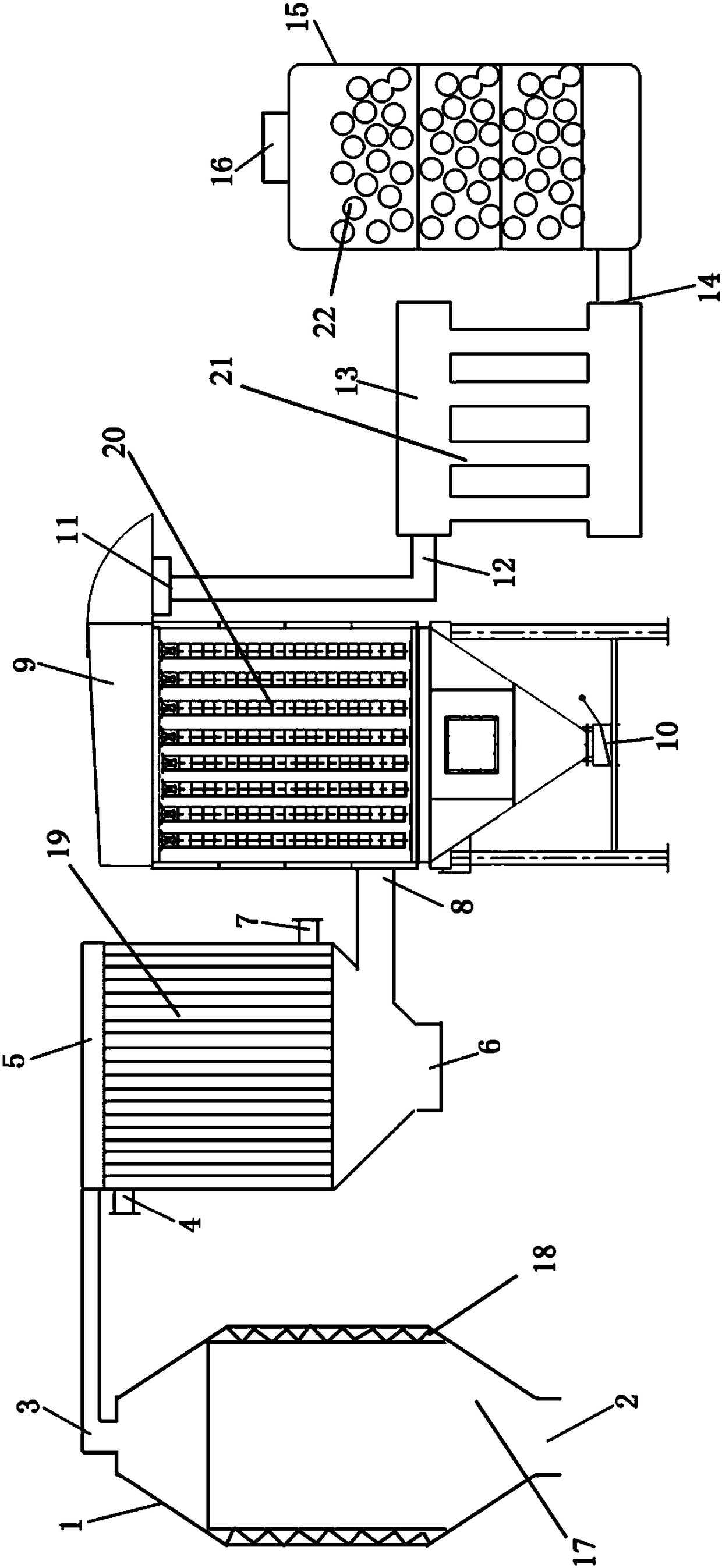

[0022] Such as figure 1 As shown, the fly ash mercury removal device includes a thermal analysis unit 1 , a plasma reactor 13 and an adsorption unit 15 .

[0023] In this embodiment, the thermal analysis unit 1 is a drum-type heating furnace as an example. The drum 17 is made of heat-resistant stainless steel, and electric heating is adopted. The electric heating wire 18 is arranged on the outer periphery of the drum 17 . The maximum heating temperature of the heating furnace is set to 800°C, and the drum 17 can be in direct contact with the material. After the material leaves the furnace, it is naturally cooled in the cooling section of the drum 17. The solid is discharged through the receiving port 2, and the dusty gas is discharged through the exhaust port 3. The thermal desorption unit 1 may also include additives, such as at least one of sublimated sulfur, sodium su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com