Piano shell high-pressure airless spraying device

A high-pressure airless, spraying device technology, applied in the direction of spraying devices, liquid spraying devices, etc., to achieve the effect of saving spraying time, reducing pollution, and reducing health injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below.

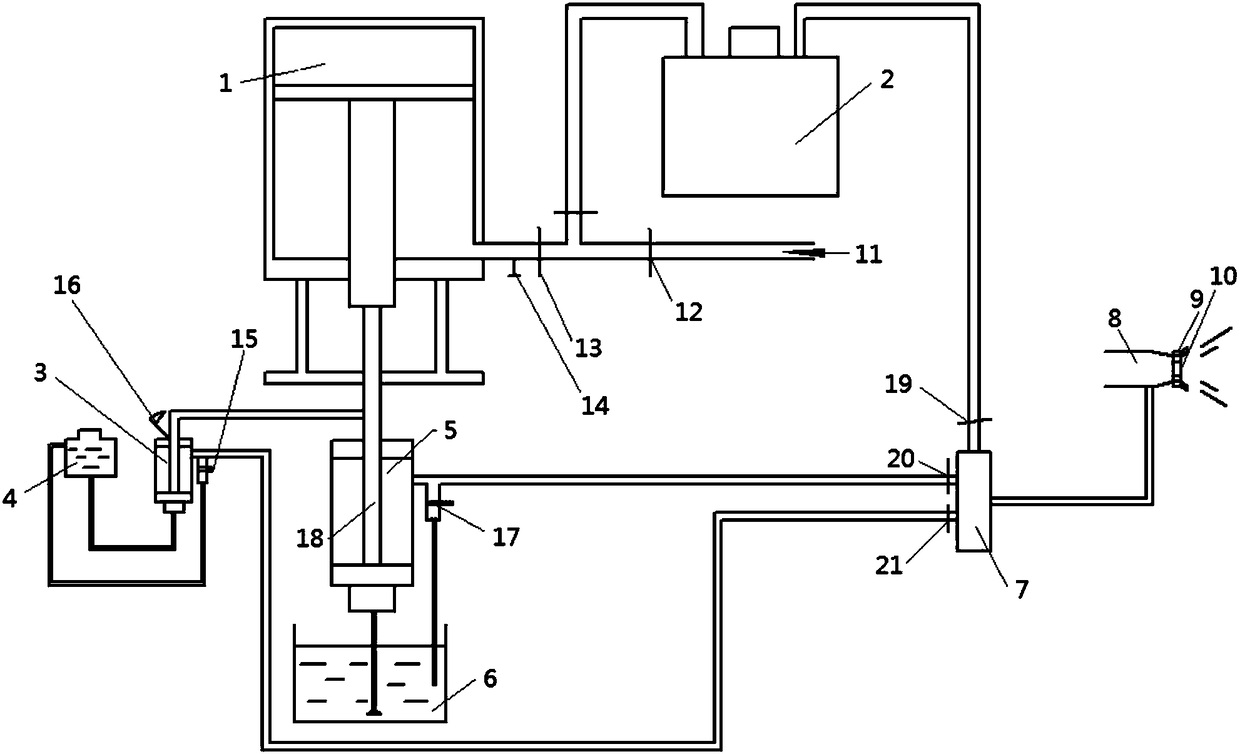

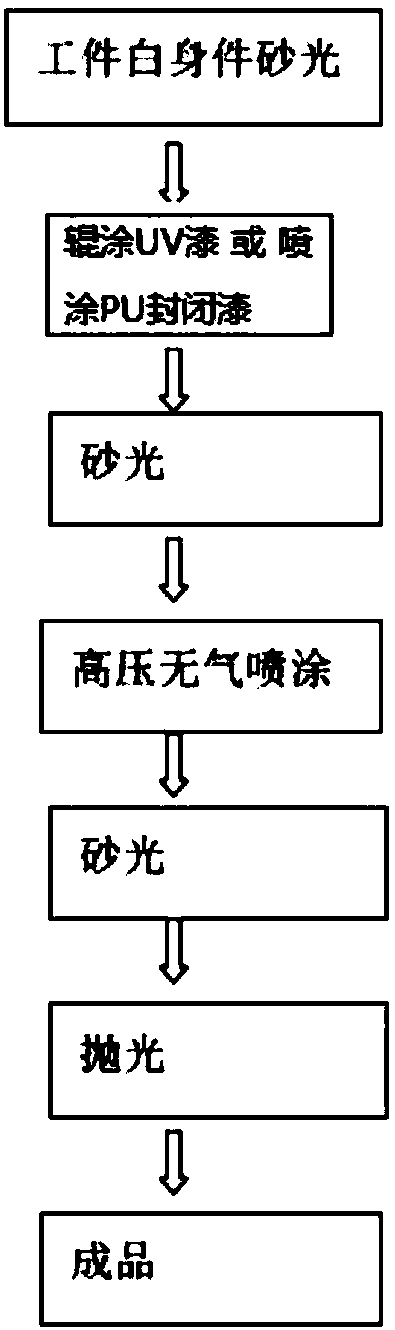

[0028] A high-pressure airless spraying device for piano shells, including an air source, a gas booster, a material pump, a material barrel, a curing agent pump, a curing agent barrel, a static mixer, a spray gun, a spray cap, a nozzle, two return valves, and a pressure tank , General air intake switch, pneumatic air source switch, air source regulating valve, pressure tank air source switch, cleaning switch, A switch, B switch.

[0029] The air booster is an air motor, which is used to transmit and pressurize the gas, and finally drive the material pump and curing agent pump to run. Both the material pump and the curing agent pump are live column pumps, which are used to change low-pressure liquid into high-pressure liquid, including gas inlet, low-pressure liquid inlet, and high-pressure liquid outlet. The function of the static mixer is to mix two high-pressure liquids evenly. The nozzle is a 417 ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com