An infrared LED light source

A technology of LED light source and near-infrared light, which is applied in the field of infrared LED light source, can solve the problems of difficulty in obtaining high-efficiency infrared LED light source, low phosphor efficiency, low efficiency, etc., achieve high luminous brightness, improve luminous efficiency, and high emission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

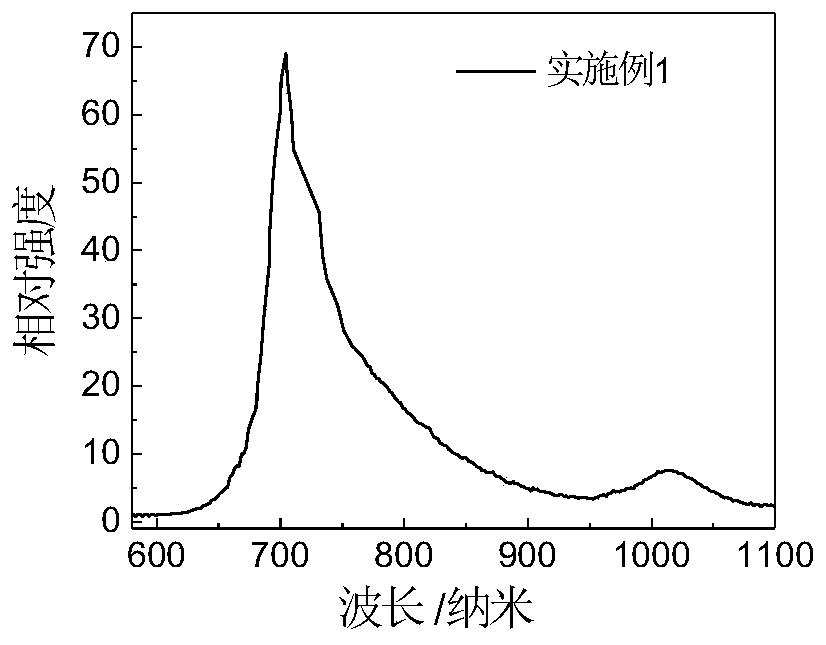

Embodiment 1

[0076]A patch-type bracket is selected, and the blue LED chip with a wave peak range of 450-452nm is fixed in the bracket bowl cup through a crystal-bonding process, and the wire welding is completed. Weigh 5g of Zn 3 Ga 1.98 GeO 8 :Cr 0.02 After the phosphor powder is mixed with 6g of organic silica gel, it is poured into the bowl cup through the dispensing process, and then through the curing process, a patch-type infrared LED light source with a spectral coverage of 700-850nm can be obtained. The luminous brightness is 120% of that of Comparative Example 1.

Embodiment 2

[0078] The in-line bracket is selected, and the blue LED chip with a wave peak range of 450-452nm is fixed in the bracket bowl cup through the crystal bonding process, and the wire welding is completed. Weigh 3.5g of Zn 3 Ga 1.9788 GeO 8 :Cr 0.02, Nd 0.0012 After the phosphor powder is mixed with 6g of organic silica gel, it is poured into the bowl through the dispensing process, and then the in-line infrared LED light source with a spectral coverage of 700-850nm can be obtained through the curing process. The luminous brightness is 118% of that of Comparative Example 1.

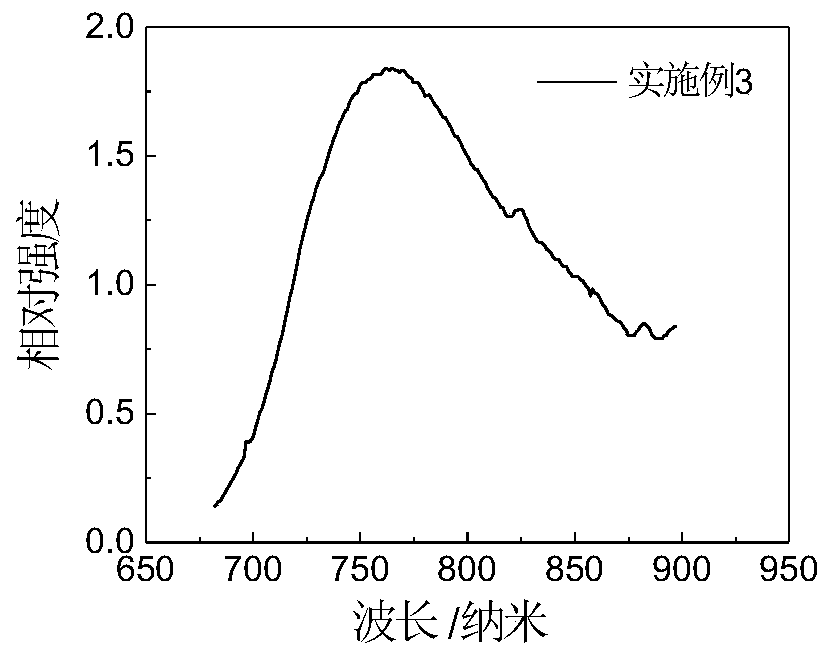

Embodiment 3

[0080] A patch-type bracket is selected, and the blue LED chip with a wave peak range of 455-460nm is fixed in the bracket bowl cup through a crystal-bonding process, and the wire welding is completed. Weigh 5g of Zn 3 Ga 1.946 Ge 2 o 10 :Cr 0.054, After the phosphor powder is mixed with 8.3g of organic silica gel, it is poured into the bowl through the dispensing process, and then through the curing process, a patch-type infrared LED light source with a spectral coverage of 750-850nm and a peak wavelength of about 770nm can be obtained. The luminous brightness is 135% of that of Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com