Single-camera motion detection method and device for the number of ultra-high stacked and ultra-thin cigarette labels

A motion detection, single-camera technology, used in image data processing, image analysis, image enhancement, etc., can solve problems such as increased cost, increased number of cameras, and inability to balance, and achieve improved accuracy and error, high detection accuracy, and real-time performance. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

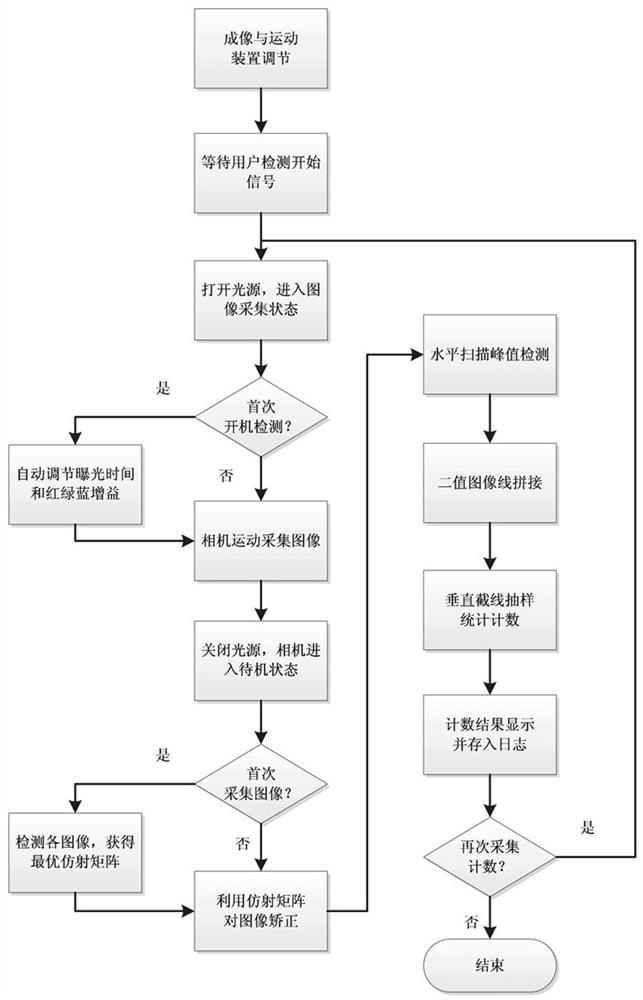

[0036] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

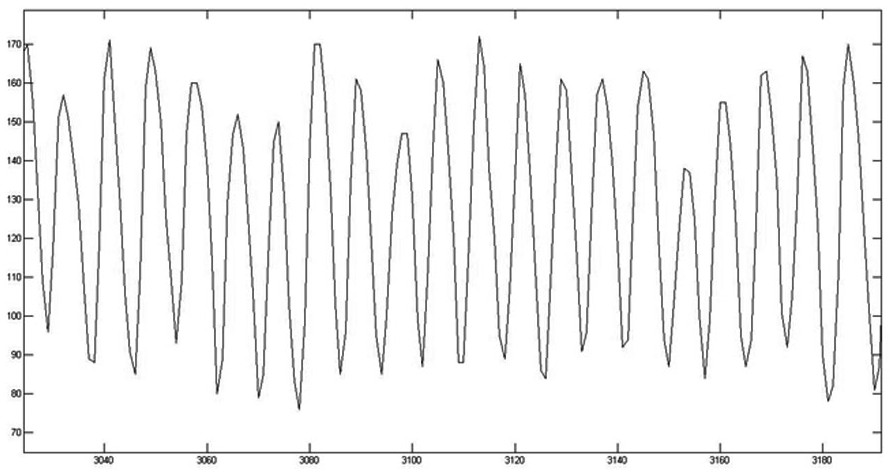

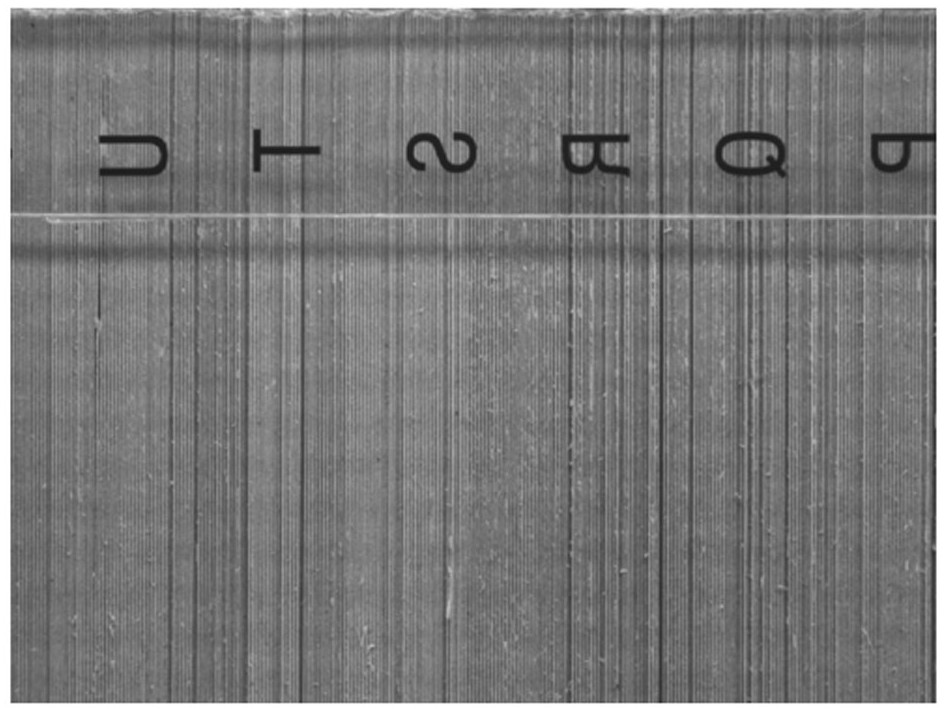

[0037] like figure 1 As shown, a single-camera motion detection method for the number of ultra-high laminated and ultra-thin cigarette labels of the present invention, the steps are:

[0038] S1: Set up the imaging and movement device: adjust the focal length of the camera according to the imaging resolution requirements of the cigarette label, and then adjust the movement position of each measuring station of the camera according to the thickness of the cigarette label stack, so that the images collected by the movement have enough overlapping areas; it mainly includes Focus the lens, adjust the aperture and adjust the range, and under the condition of ensuring that there is enough overlapping area between the images collected by two adjacent camera movements, initialize the movement device according to the actual situation, which incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com