Cam curve design method for cap screwing machine based on polynomial fitting

A polynomial fitting, cam curve technology, applied in the field of mechanical design, can solve the problems of large noise of capping machine, high polynomial power, large dynamic stress of components, etc., to achieve improved dynamic performance, good smoothness, and noise reduction and vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention proposes a method for designing a cam curve of a capping machine based on polynomial fitting, comprising the following steps:

[0032] Step 1. Take the data that the cam follower of the capping machine reaches the corresponding displacement point at the corresponding angle as the key points; these key points generally support the capping machine to complete functions such as capping, bottle feeding, and capping;

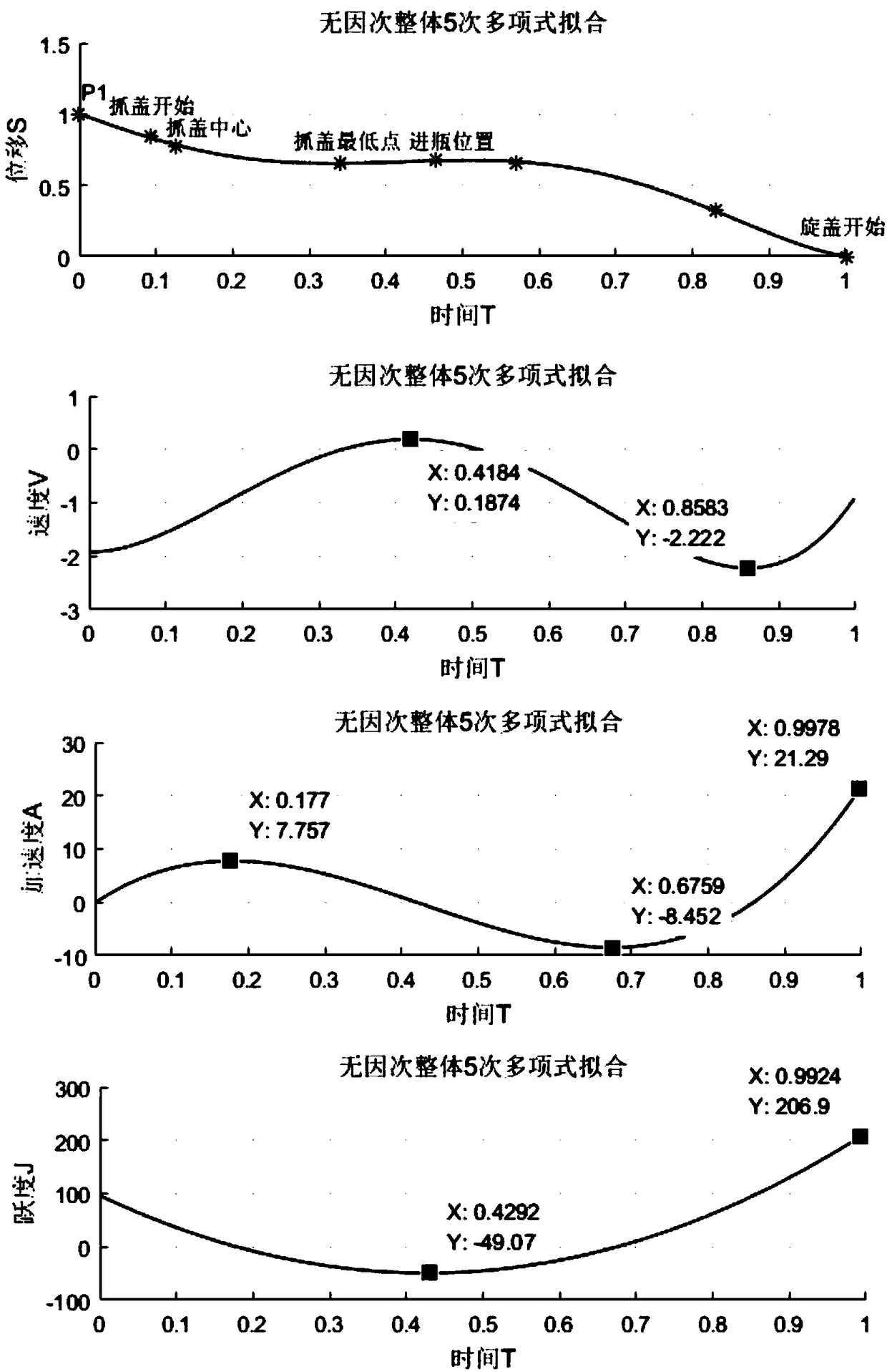

[0033] Step 2. Dimensionalize the key point data to obtain dimensionless time T and dimensionless displacement S;

[0034] Step 3, write the polynomial fitting program by MATLAB, combine the constraint condition to key point displacement, utilize least squares method, obtain n degree polynomial fitting cam curve displacement function expression and graph, described n degree polynomial fitting cam curve displacement The function expression is: S=C 0 +C 1 T+...+C n T n , where n is 5, 6 or 7, C 0 , C 1 ,...,C n is a coefficient; in o...

Embodiment 2

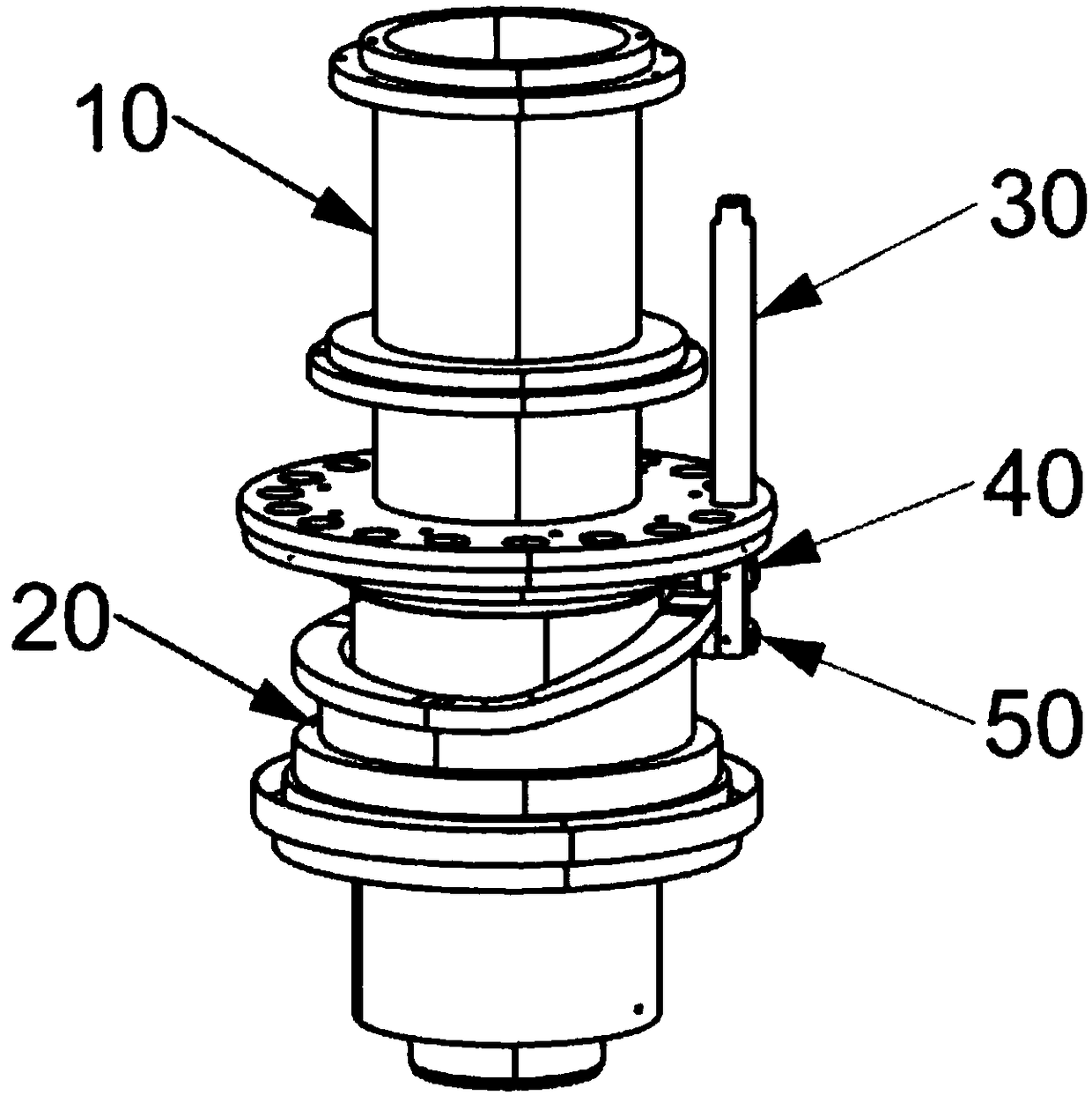

[0056] Such as figure 1 As shown, the capping machine cam mechanism used in the present invention is mainly composed of cam central shaft 10, cam 20, follower 30, follower upper roller 40 and follower lower roller 50 and other components. During operation, the cam portion remains fixed, the cam central shaft 10 rotates 20 relative to the cam, and the upper roller 40 and the lower roller 50 of the follower roll around the cam central shaft 10 along the cam profile, pushing the cam follower 30 to move up and down along the hub.

[0057] Such as figure 2 As shown, the cam follower of the capping machine used needs to reach the corresponding displacement point at the corresponding angle to complete the actions from bottle output, cap grasping, bottle feeding to cap screwing. These displacement points are referred to as key points, and the allowable design error at the key points is specified to be 1mm. It is known that the cam mechanism exits the bottle position point (0°) to P1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com