400-volt combined terminal box component

A technology of combining junction boxes and components, applied in the parts, measuring devices, instruments and other directions of electrical measuring instruments, can solve the problems of error-prone wiring, cross-phase wiring, messy circuit layout, etc., to achieve clear and clear phases and easy operation. Quickly and achieve the effect of live work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

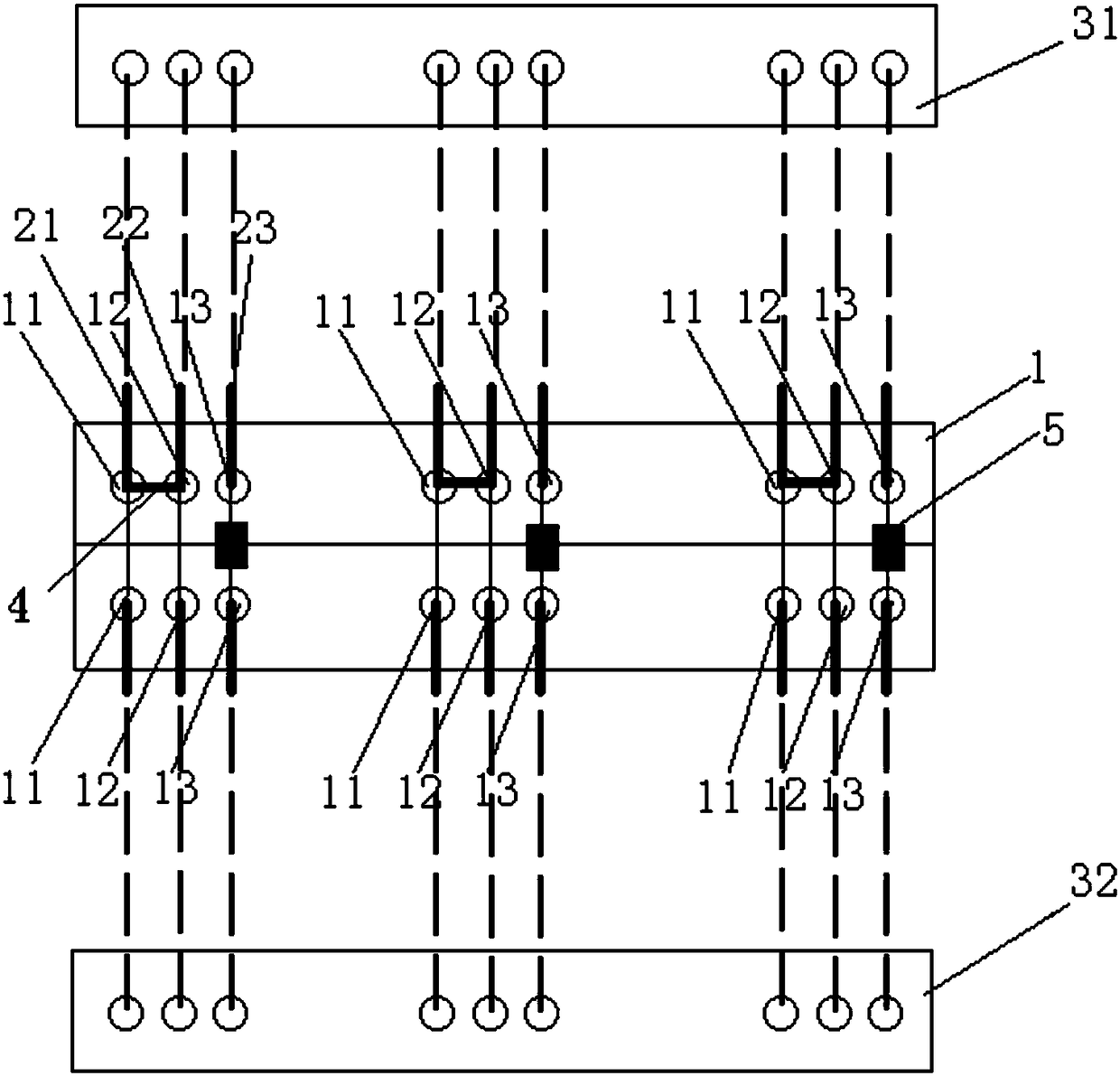

[0012] see figure 1 , a 400-volt combined junction box assembly of the present invention includes a combined junction box base 1 and a phase-splitting lead-out device.

[0013] The current transformers are installed in groups of three, so when connecting the lead wires of the current transformers to the meter, they should also be installed in groups of three. The lead-out lines of any current transformer are divided into P1 current-phase lead-out lines, P2 current-phase lead-out lines and voltage-phase lead-out lines. For these three phases, three P1 current-phase phase-splitting holes 11, three P2 current-phase phase-splitting holes 12, and three voltage-phase phase-splitting holes 13 are opened on the upper and lower sides of the joint junction box base 1, and one P1 The curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com