A substation contact grinding mechanism, grinding robot, system and method

A grinding mechanism and substation technology, applied in the field of robotics, can solve the problems of inability to grind the isolation switch contacts, inability to carry out live maintenance operations, and inability to replace the working tools in real time for the isolation switch contacts, so as to improve conversion efficiency and conversion stability High performance, simplified structure, and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

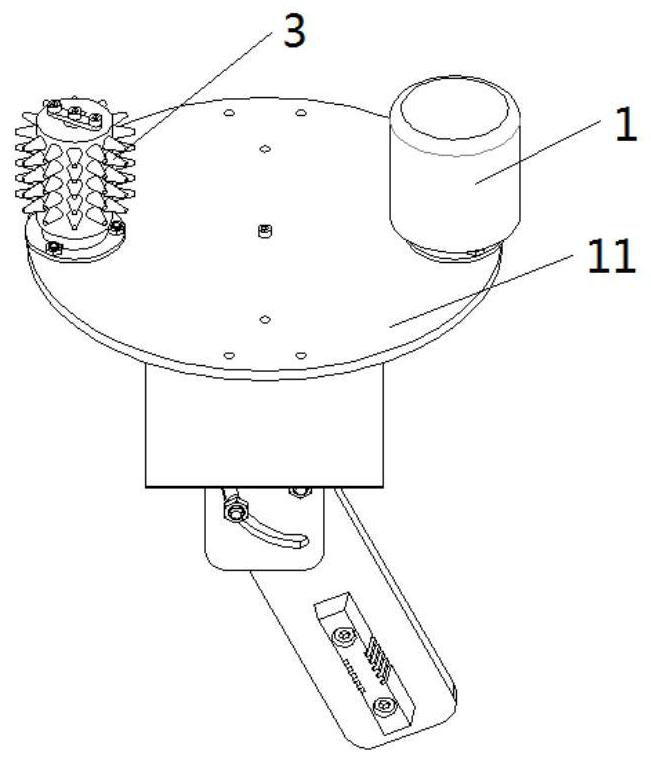

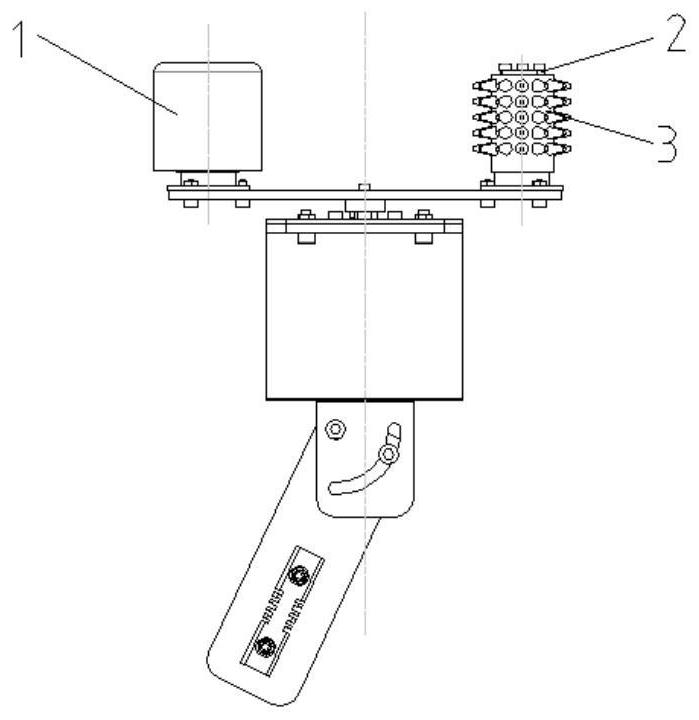

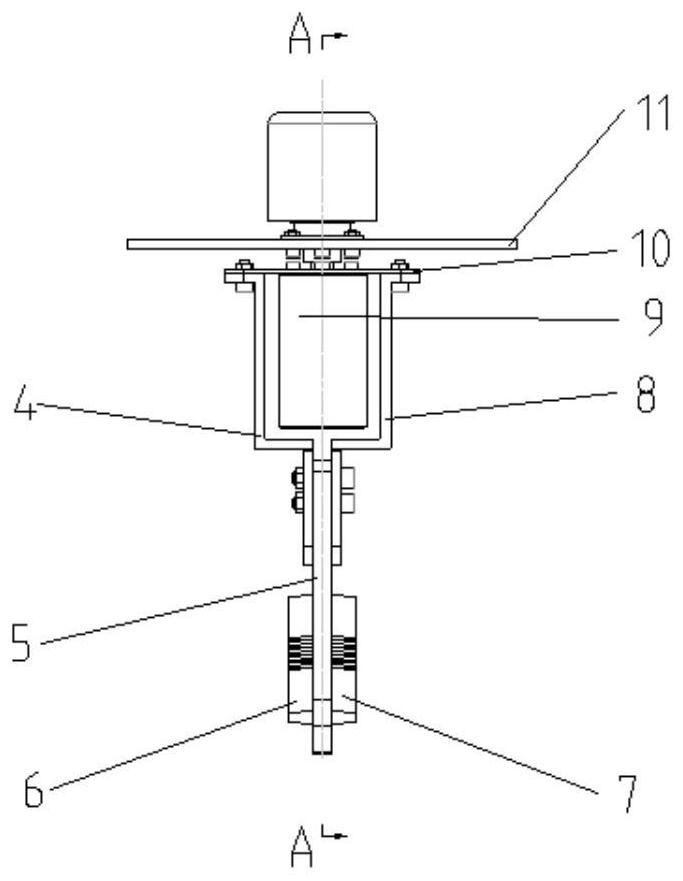

[0053] Such as figure 1 As shown, a kind of substation contact grinding mechanism of this embodiment includes:

[0054] The grinding part includes a grinding head module and a cleaning module; the grinding head module is used for grinding the disconnector switch contact to be polished; the cleaning module is used for grinding the disconnector switch contact cleaning job;

[0055] The control unit is configured to receive the finishing signal of the grinding operation of the grinding head module, switch to the cleaning module and start the cleaning work;

[0056] a connecting part, which is configured to connect the grinding part and the robotic arm of the robot, and adjust the angle between the grinding part and the mechanical arm of the robot within a preset angle range to match the position of the contact of the isolating switch knife switch to be polished, Realize the live operation of the substation contact grinding mechanism.

[0057] Such as Figure 2-Figure 4 As sho...

Embodiment 2

[0078] Such as Figure 5-Figure 7 As shown, a grinding robot of this embodiment includes the substation contact grinding mechanism as described in Embodiment 1.

[0079] It should be noted that the mechanical arms included in a grinding robot in this embodiment are all existing structures.

Embodiment 3

[0081] A polishing robot system in this embodiment includes the polishing robot described in Embodiment 2.

[0082] The working method of the grinding robot system of the present embodiment includes:

[0083] Adjust the angle between the grinding part and the robotic arm of the robot, so that the angle matches the grinding position of the contact of the isolating switch knife switch to be ground;

[0084] Control the grinding head module to perform the grinding operation on the isolating switch knife switch contact to be polished, and send the grinding operation end signal to the control department when the grinding head module finishes the grinding operation;

[0085] Receive the grinding operation end signal of the grinding head module, switch to the cleaning module and start the cleaning work. The robot is equipped with laser, vision, ultrasonic and leakage current sensors, which can monitor the status of the robot, tools and equipment during the grinding operation at any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com