Abrasion monitoring instrument of digital displaying bearing

A bearing wear and monitoring instrument technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of motor burnout, poor precision, bearing wear, etc., and achieve the effect of preventing equipment accidents and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

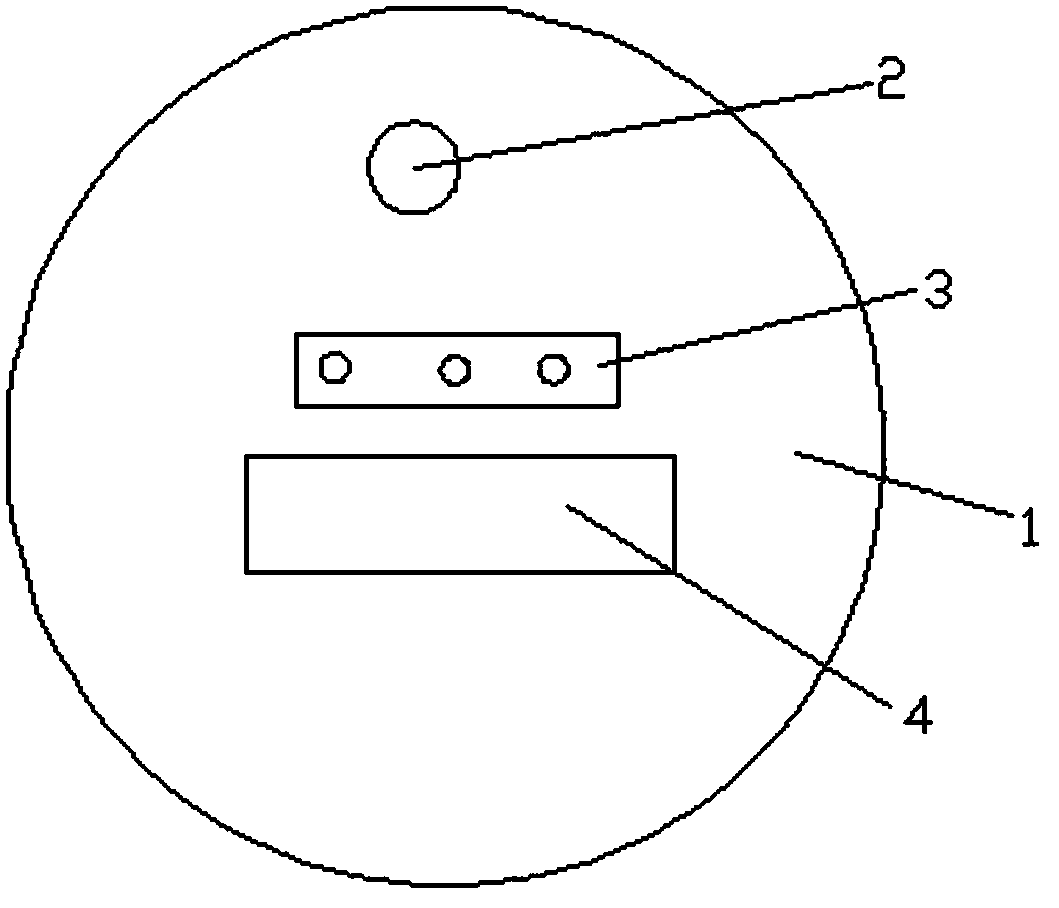

[0028] see figure 1 , this embodiment relates to a digital display bearing wear monitoring instrument, including a housing 1, the housing 1 is provided with a phase sequence alarm indicator light 2, a wear status indicator light 3 and a wear amount display area 4, and the housing 1 is internally provided with There is an integrated circuit, which directly converts the G1 and G2 AC signals drawn from the motor into digital signals, and the integrated circuit includes a main control circuit, a display circuit, a phase sequence indicating circuit, and a power input and current output circuit;

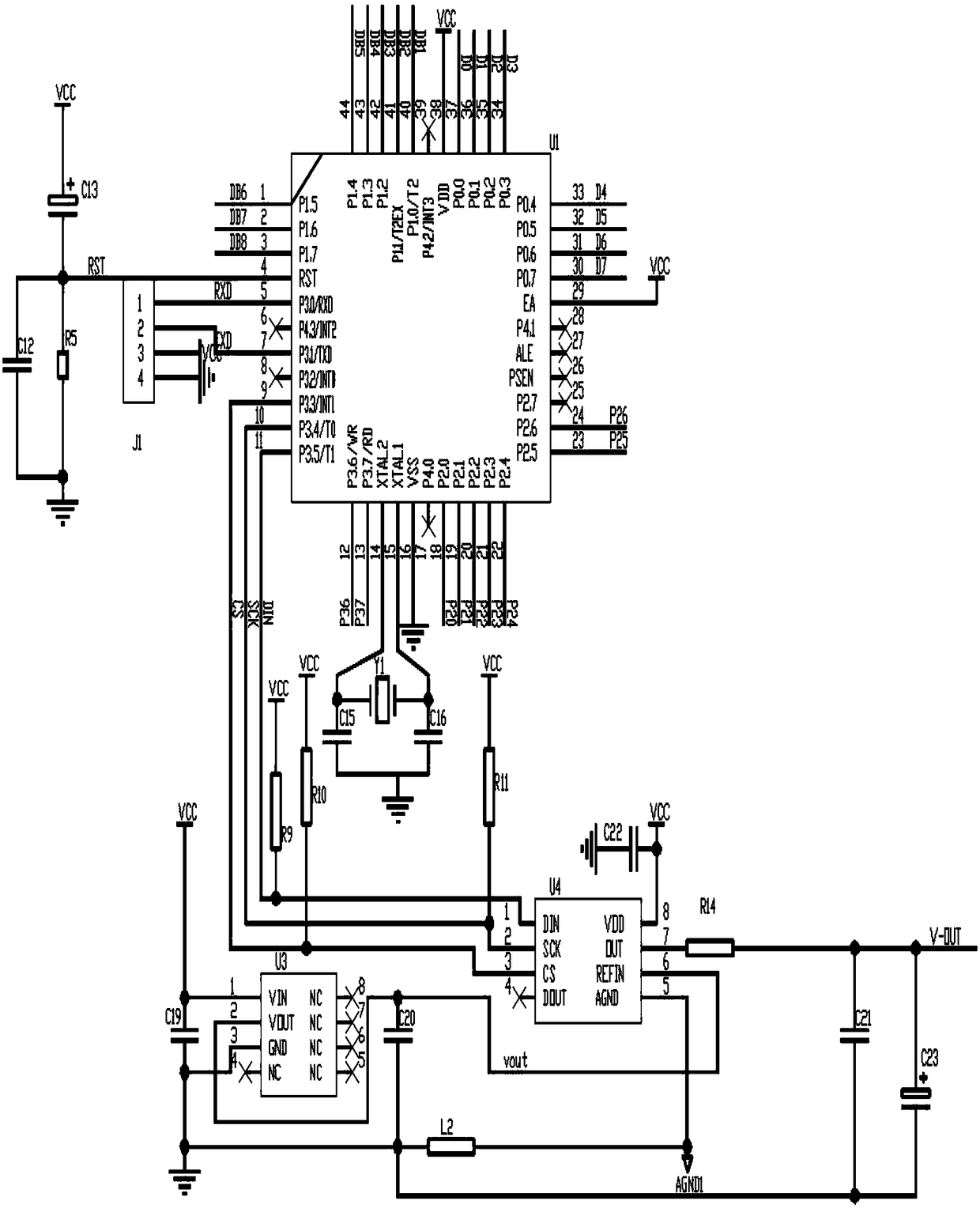

[0029] The main control circuit includes an analog quantity acquisition filter circuit and a DAC signal conversion circuit,

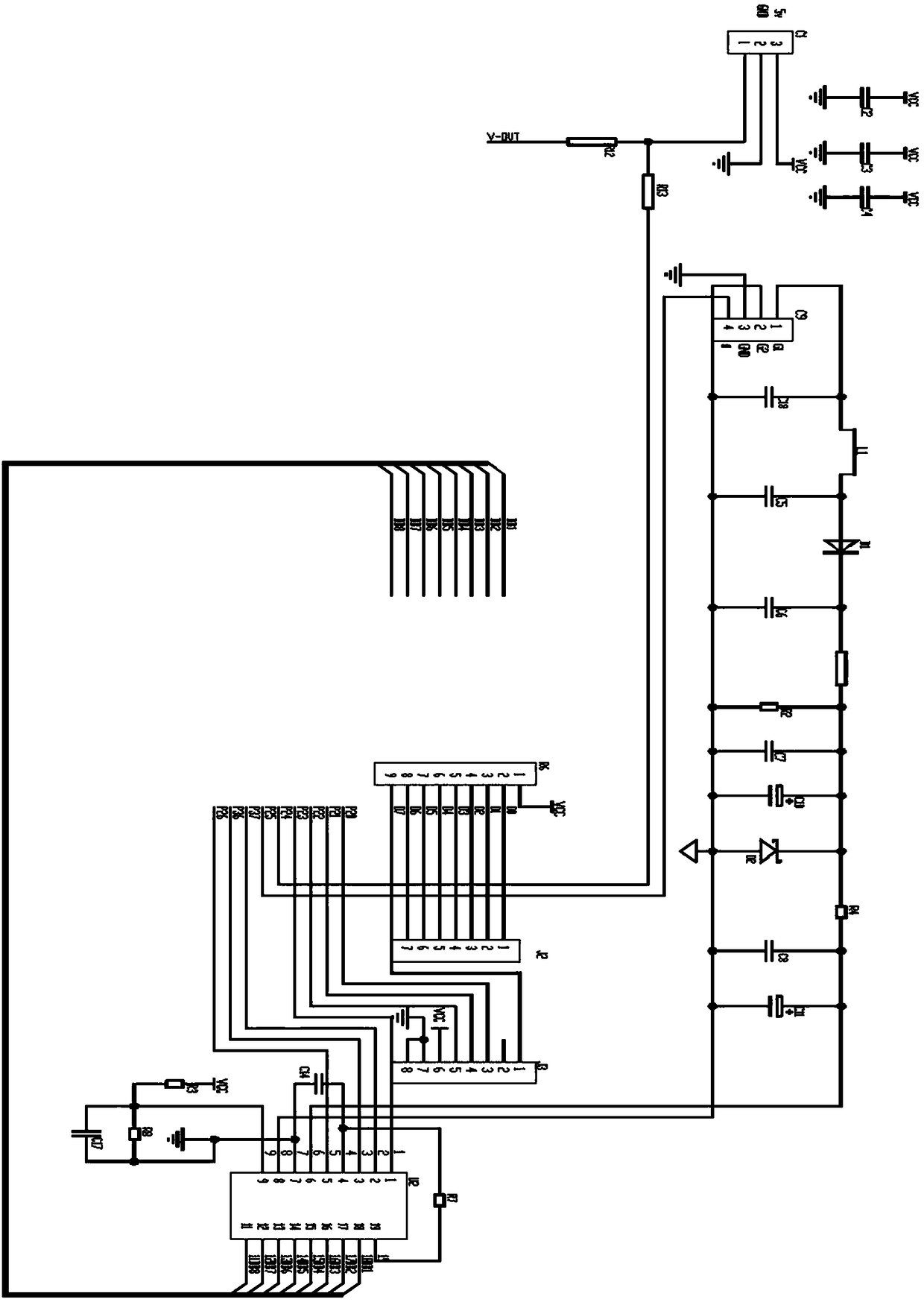

[0030] see figure 2 , the analog acquisition filter circuit inputs the voltage signal from the LC filter circuit composed of C18, L1, and C5, and then rectifies and filters the C10 through D1 to output a stable DC voltage signal, and then enters the digital quanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com