Shear spring

A technology of shearing springs and elastic materials, applied in springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve the problems of small force, vibration intensity, inapplicability, and low rubber strength, etc. To achieve the effect of safe and reliable use, long life and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

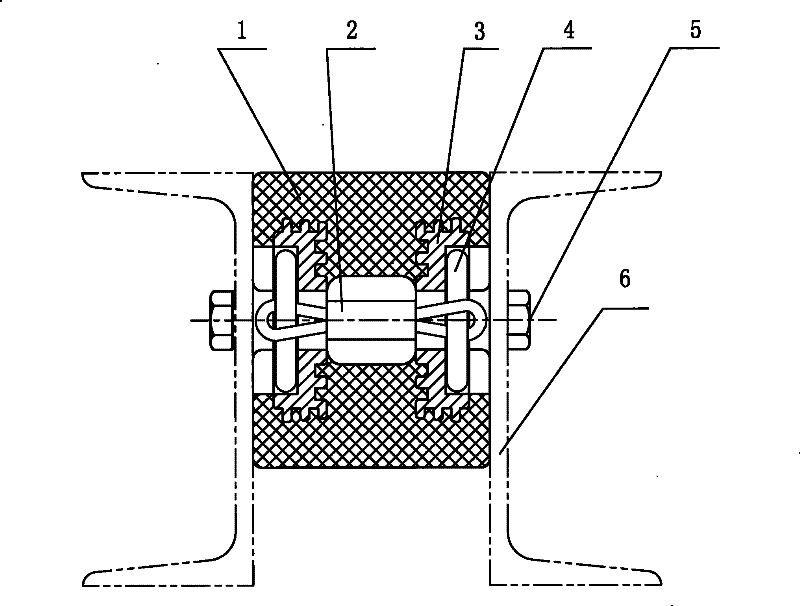

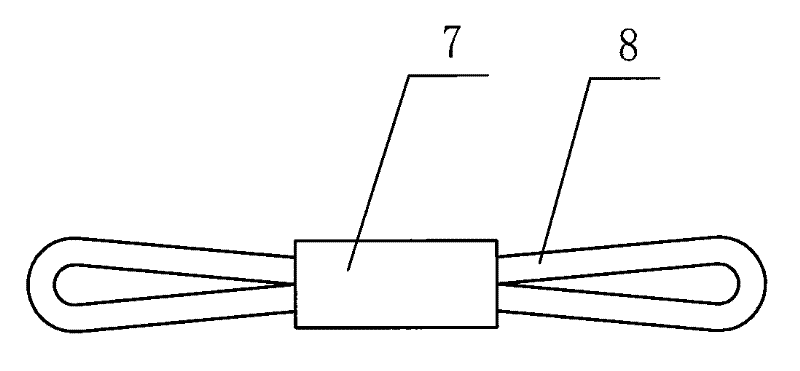

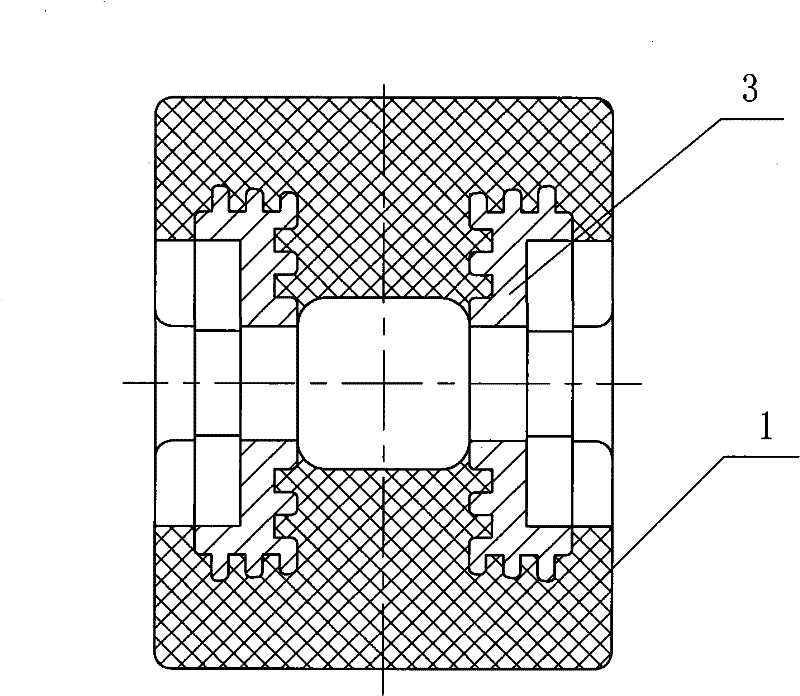

[0008] The embodiment of the present invention will now be described in conjunction with the accompanying drawings. The shear spring body 1 is a cylinder formed of polyurethane material with a hole in the middle, and two metal mounting claws 3 are pre-embedded near the two ends of the interior. 3. Threaded holes 9 for installation are processed on the top; grooves or columnar protrusions that can increase the contact surface with the polyurethane spring body are processed on the circumference and end faces. The two mounting jaws 3 are connected together by a safety wire ring 2, and the two ends are fixed by positioning pins 4. Insurance wire ring 2 is to be made by multi-strand wire rope 8, and two ends are bent to be ring-shaped, and the center is locked by pressing joint 7. When the shear spring is in use, the two end faces of the spring can be connected with the corresponding parts 6 with connecting bolts 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com