A method for identifying and diagnosing faults of a gear with single tooth cracks and broken teeth

A technology of fault identification and diagnosis method, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc. It can solve problems such as characterizing fault distances, achieve high identification and diagnosis accuracy, and avoid expansion and enlargement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A detailed description will be given below in conjunction with the accompanying drawings and the specific implementation method of the present invention on the fault detection of the gear box of the running part of the locomotive.

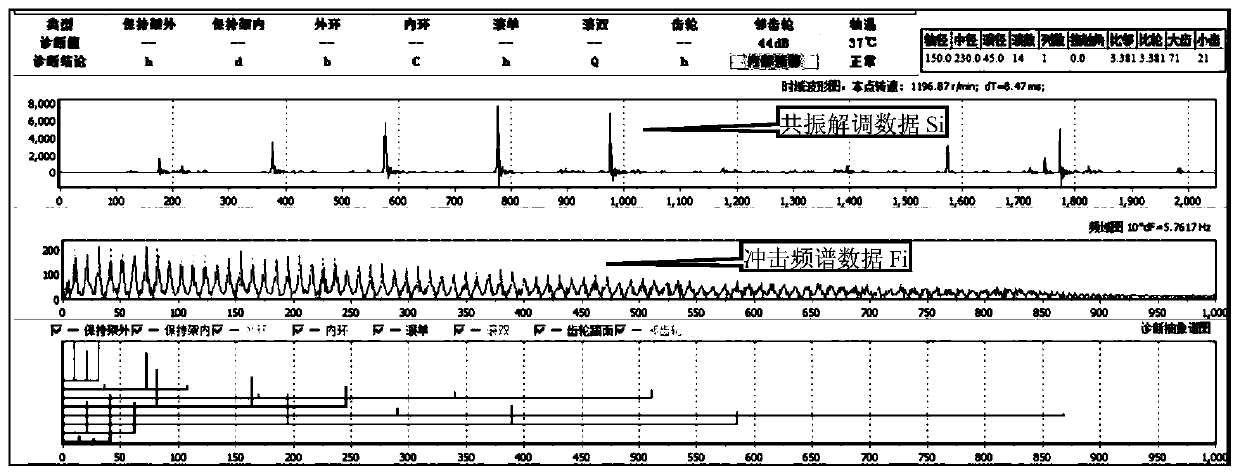

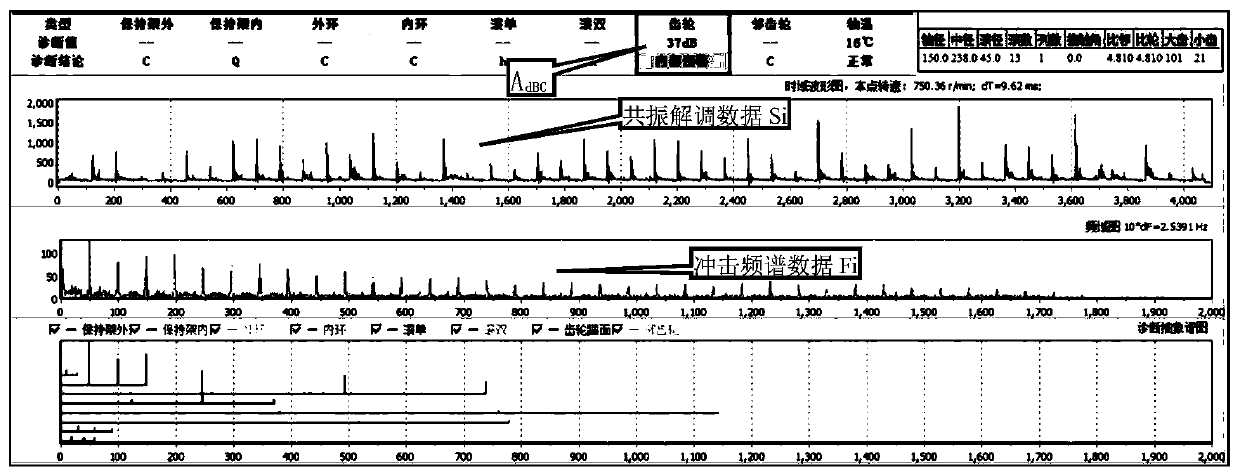

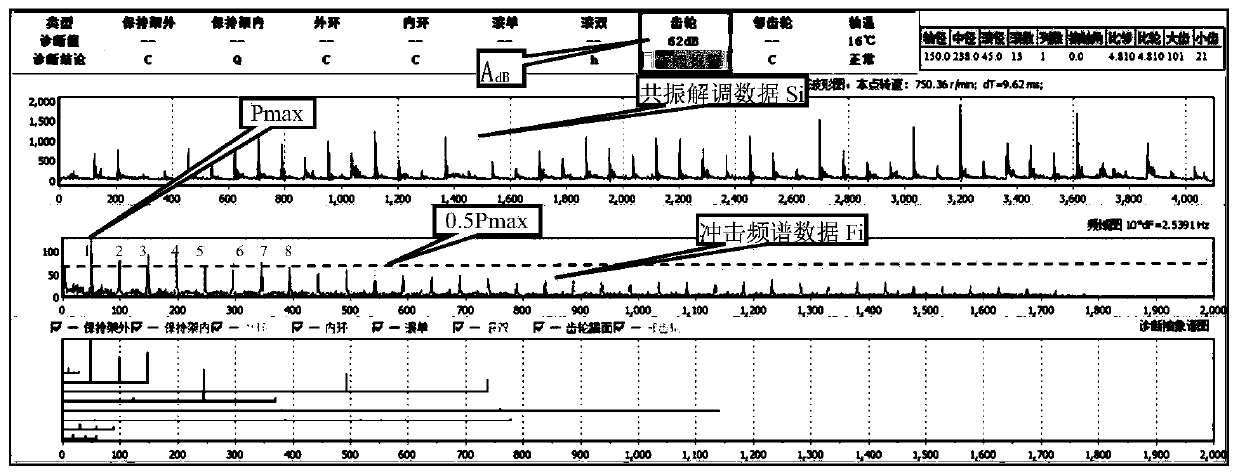

[0024] When the gears of the gear box of the running part of the locomotive are meshing, if a single tooth crack or broken tooth fault occurs, the impact process is characterized by a short time and high impact intensity; after resonance demodulation, the impact cluster is narrow and thin , but the shock amplitude is large. At the same time, this kind of impact information appears periodically according to the rotation frequency of the shaft where the gear is located. After Fourier transform, the frequency spectrum shows that the rotation frequency of the faulty gear shaft is the first-order frequency, and a large number of high-order spectra with regular attenuation appear, as shown in the attached figure 1 shown. According to Parseval's e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com