Heat exchanger for vehicle

A technology for heat exchangers and vehicles, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problem of low heat exchange performance, high manufacturing cost of shell and tube heat exchangers, and heat exchange tubes separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. For reference, the size of components and the thickness of lines in the drawings may be exaggerated for ease of understanding. In addition, the terms used in the description of the present invention may be different depending on a user, an operator's intention, or a user's consideration of functions in the present invention. Therefore, terms should be defined according to the overall disclosure herein.

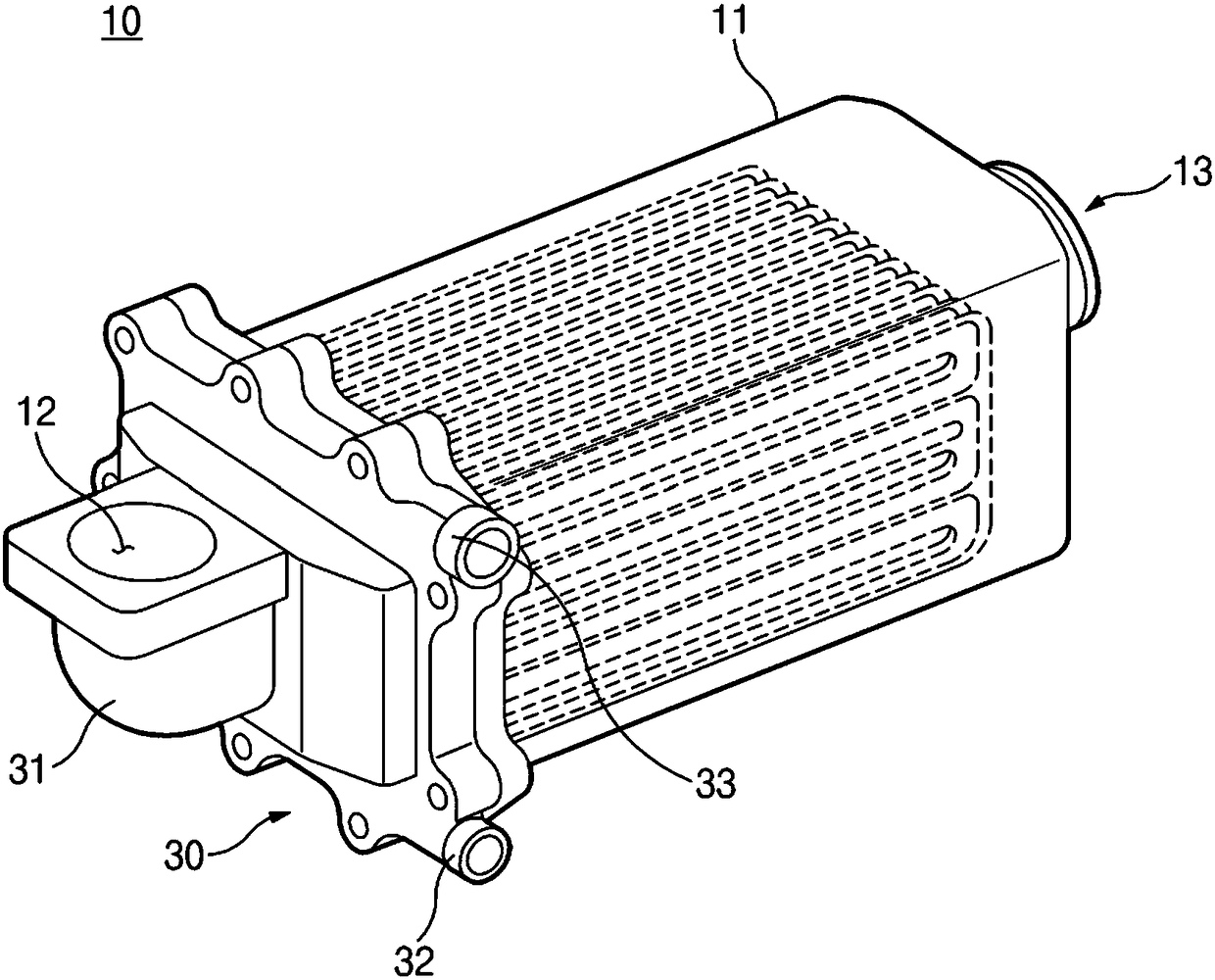

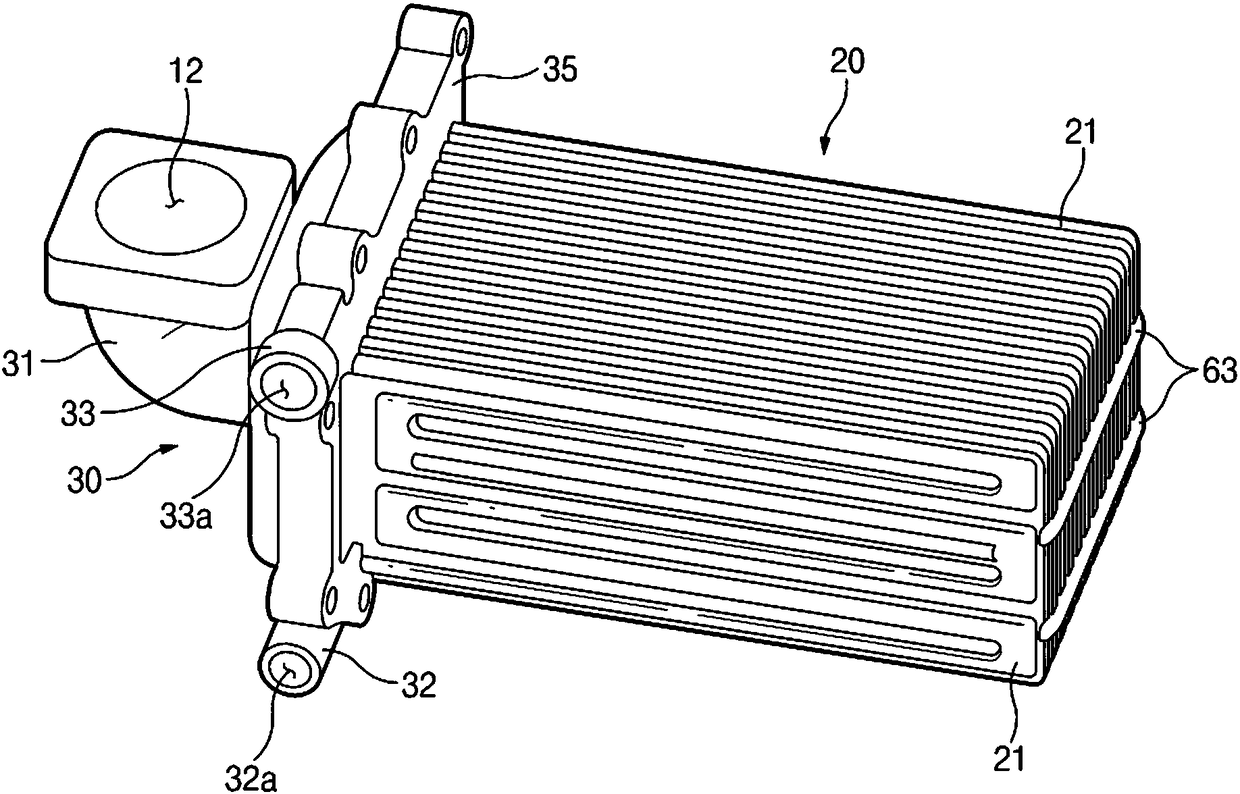

[0046] refer to Figure 1 to Figure 10 , the heat exchanger 10 for a vehicle according to various embodiments of the present invention may include a case 11 and a heat exchange core 20 installed in the case 11 .

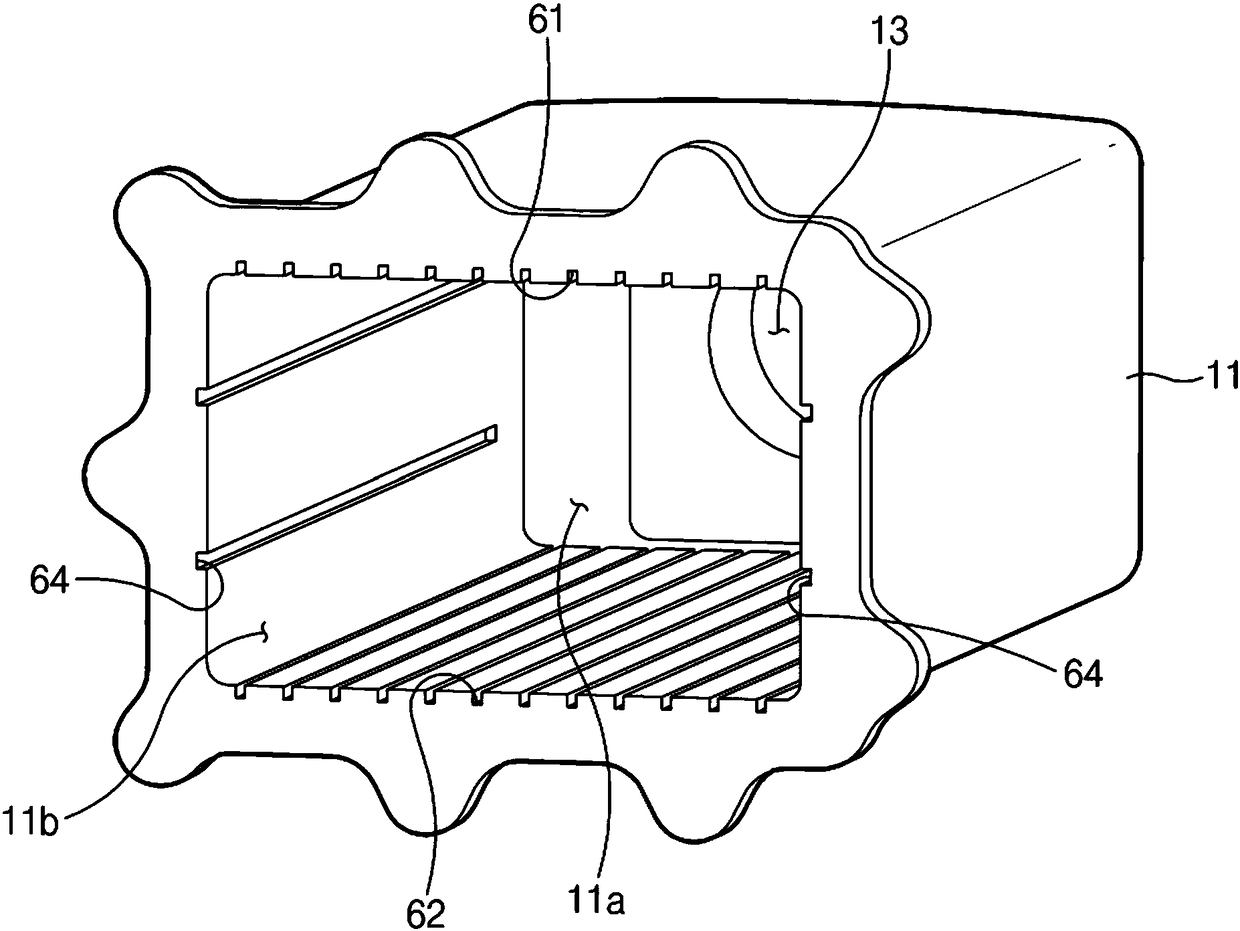

[0047] refer to figure 1 and image 3 , the housing 11 may have an inner space 11a through which the first fluid passes. The opening 11b can be installed at one end of the housing 11, the end 30 can be installed at the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com