Ash blowing explosion tank with rotatable partition plates

A technology of rotating clapboard and explosion tank is applied in the field of boiler pulse soot blowing, which can solve the problems of low filling degree of mixed gas, insufficient explosion power, low temperature dew point corrosion, etc., and achieve the effect of preventing low temperature dew point corrosion and improving the effect of soot blowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

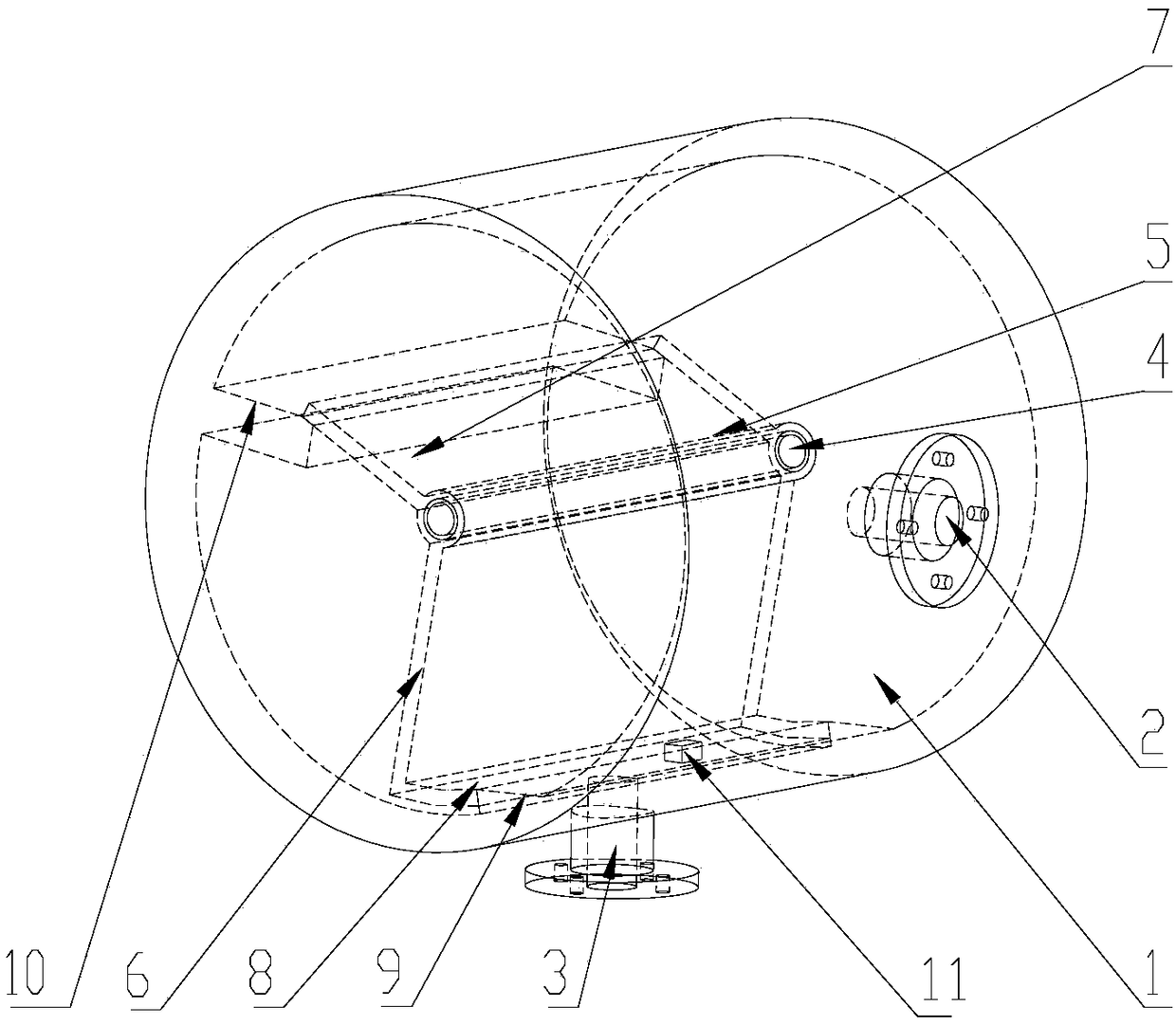

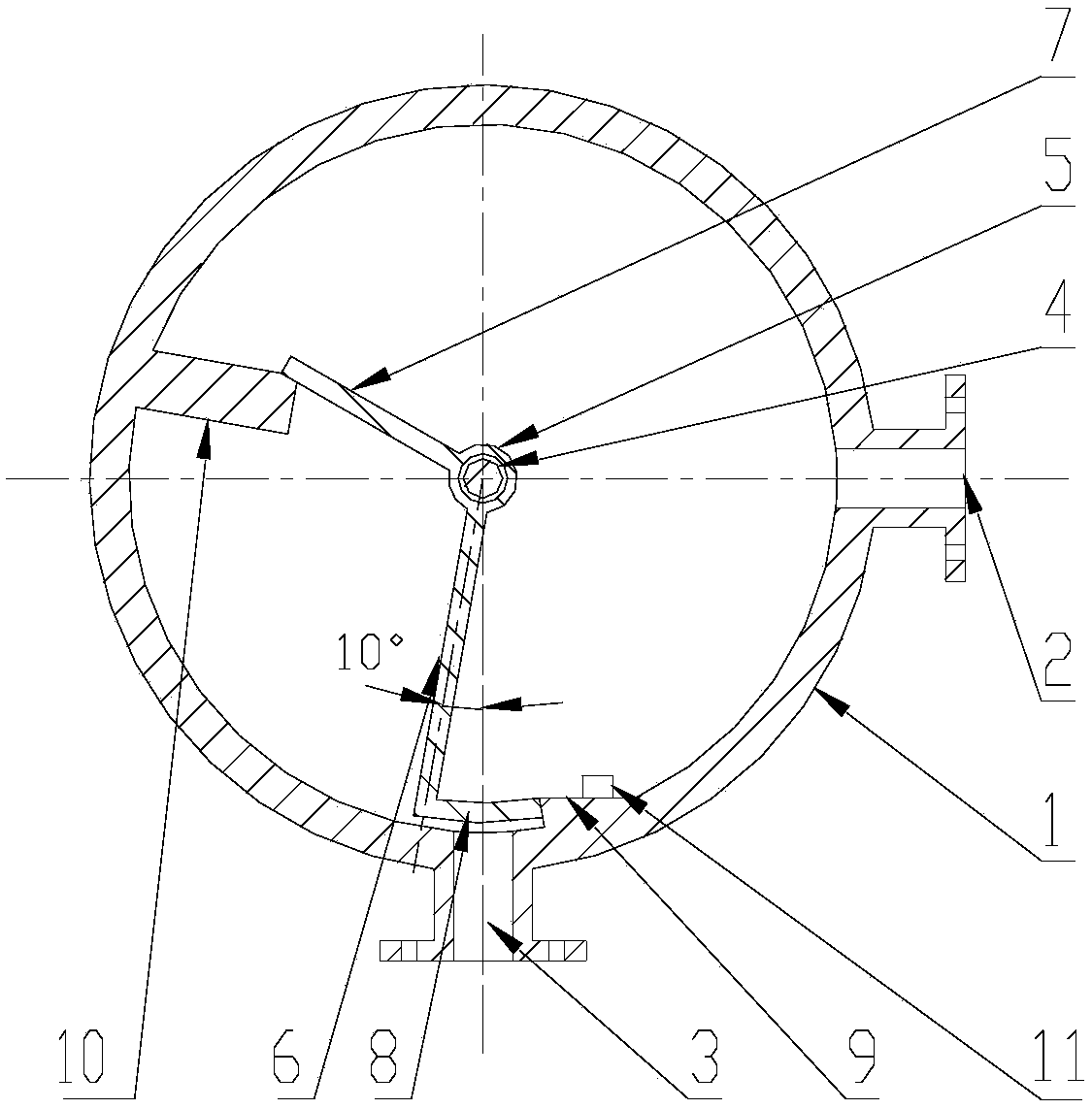

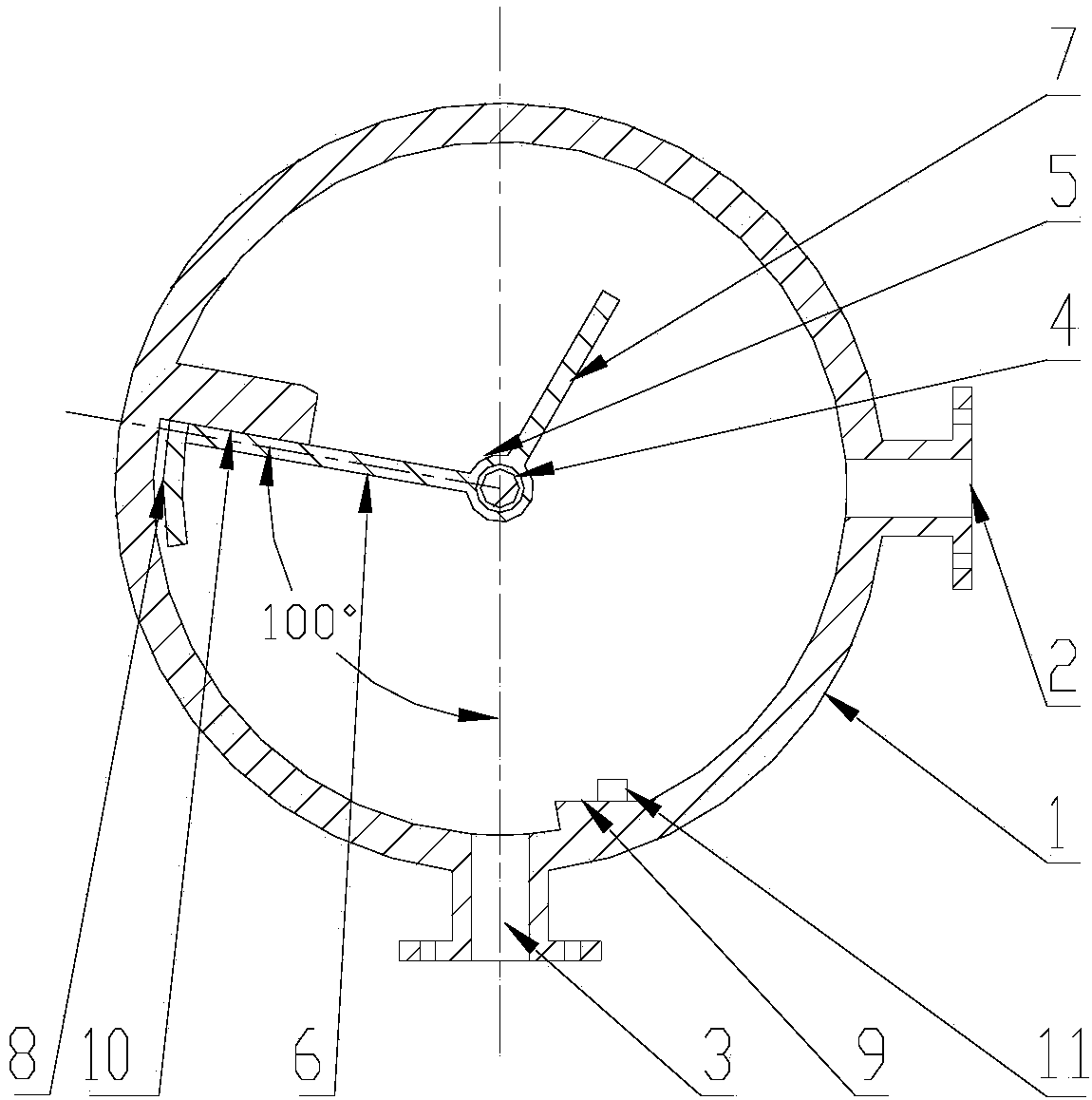

[0022] Such as figure 1 As shown, a soot blowing explosion tank with a rotatable partition in the present invention includes a tank body 1, an air inlet 2, an air outlet 3, and an ignition device 11; it also includes a shaft 4, a sleeve 5, and a first partition 6. The second partition 7 , the arc plate 8 , the first boss 9 , and the second boss 10 . The tank body 1 is a cylindrical structure with a chamber, arranged horizontally; an air inlet 2 and an air outlet 3 are arranged on the side wall of the tank body 1. As a preferred embodiment of the present invention, the direction of the air outlet 3 is vertical Downward, the air inlet 2 is perpendicular to the direction of the air outlet 3 . The shaft 4 is fixed to the tank body 1 and is located at the axis of the cylinder, and the sleeve 5 can freely rotate around the shaft 4 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com